Ethylene-acrylic bonded piston without oven post curing

一种丙烯酸聚合物、活塞的技术,应用在活塞、筒状活塞、柱塞等方向,能够解决制造成本阻碍自动变速器活塞生产等问题,达到减少环境足迹、节省制造成本、减少天气然的消耗的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

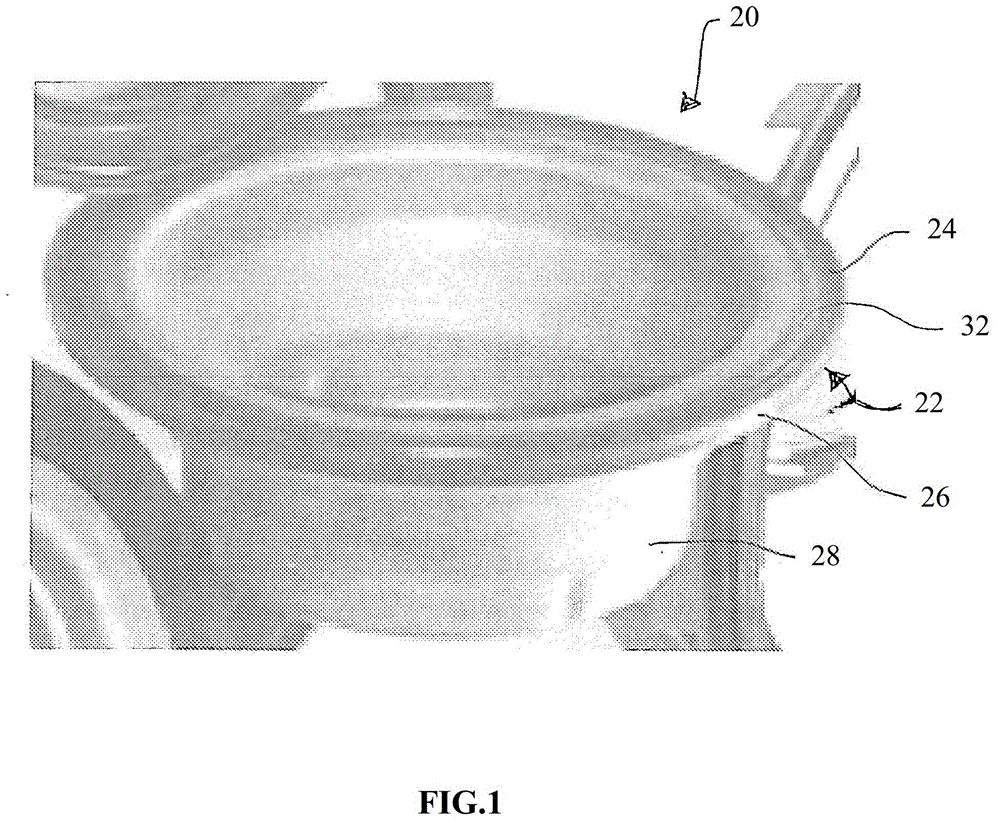

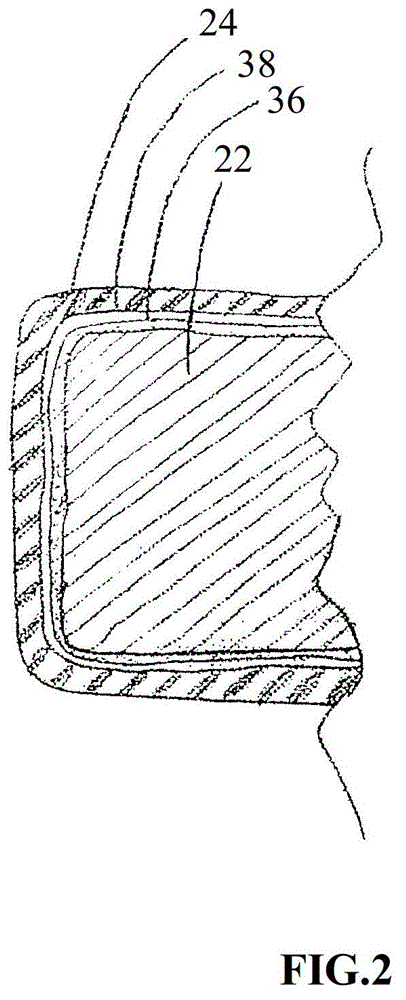

[0015] As shown in FIG. 1 , a typical piston 20 for an automatic transmission includes a cylindrical portion 22 made of a metal material and an elastic body 24 coupled to the cylindrical portion 22 . The method of making piston 20 involves coupling the elastomer to cylindrical portion 22 without going through a post-curing step.

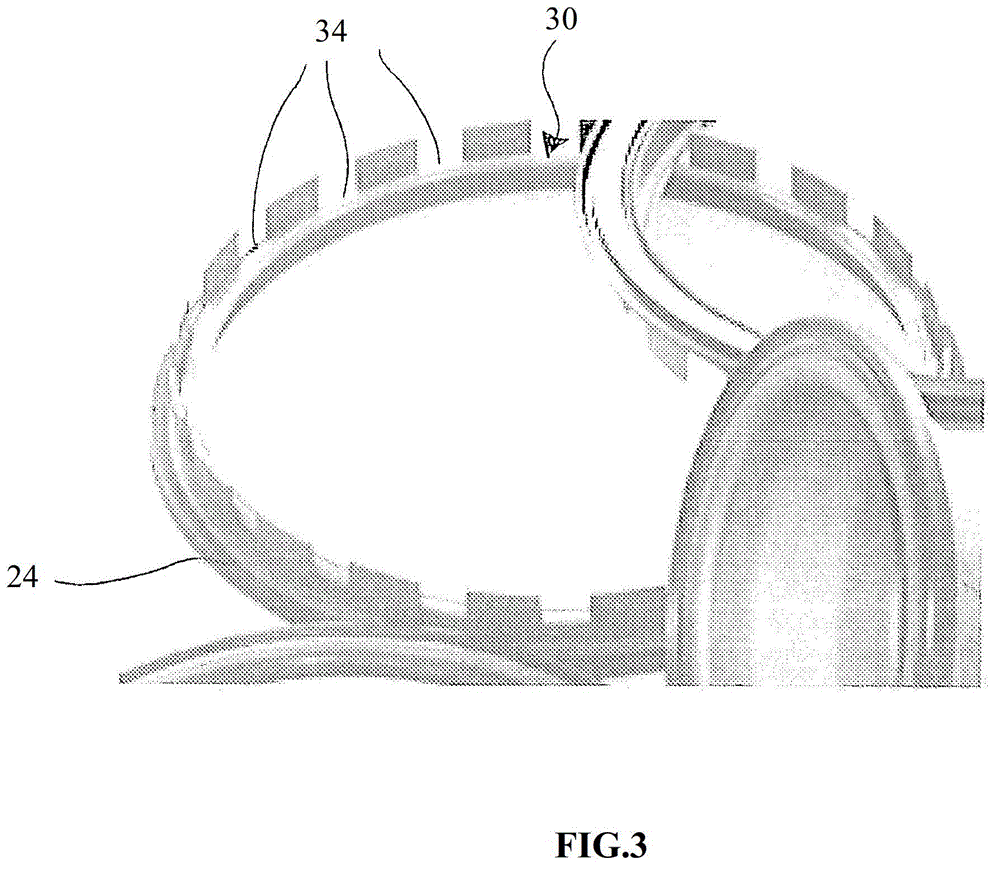

[0016] The cylindrical portion 22 of the piston 20 is made of a metallic material such as steel 1010 . The cylindrical portion 22 can also be made of other kinds of steel, aluminum, aluminum alloy or other metal materials. As shown in FIG. 1 , the cylindrical portion 22 of the piston 20 may include a crown 26 and a skirt 28 surrounding the central opening. As shown in Figures 3 and 4, the cylindrical portion 22 may also include a cylindrical ring 30, or other designs suitable for automatic transmission systems. Cylindrical portion 22 generally includes a top surface, an inner surface, and an outer surface.

[0017] As shown in FIG. 1 , the cylindr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com