Control system and control method of surface air speed of fume hood

A control system and fume hood technology, which are applied in cleaning methods and utensils, chemical instruments and methods, and smoke and dust removal, etc., can solve the problems such as the inability to open and effectively adjust the size of the fume hood cabinet surface, reduce energy consumption, and improve the experimental environment. , the effect of reducing wind noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

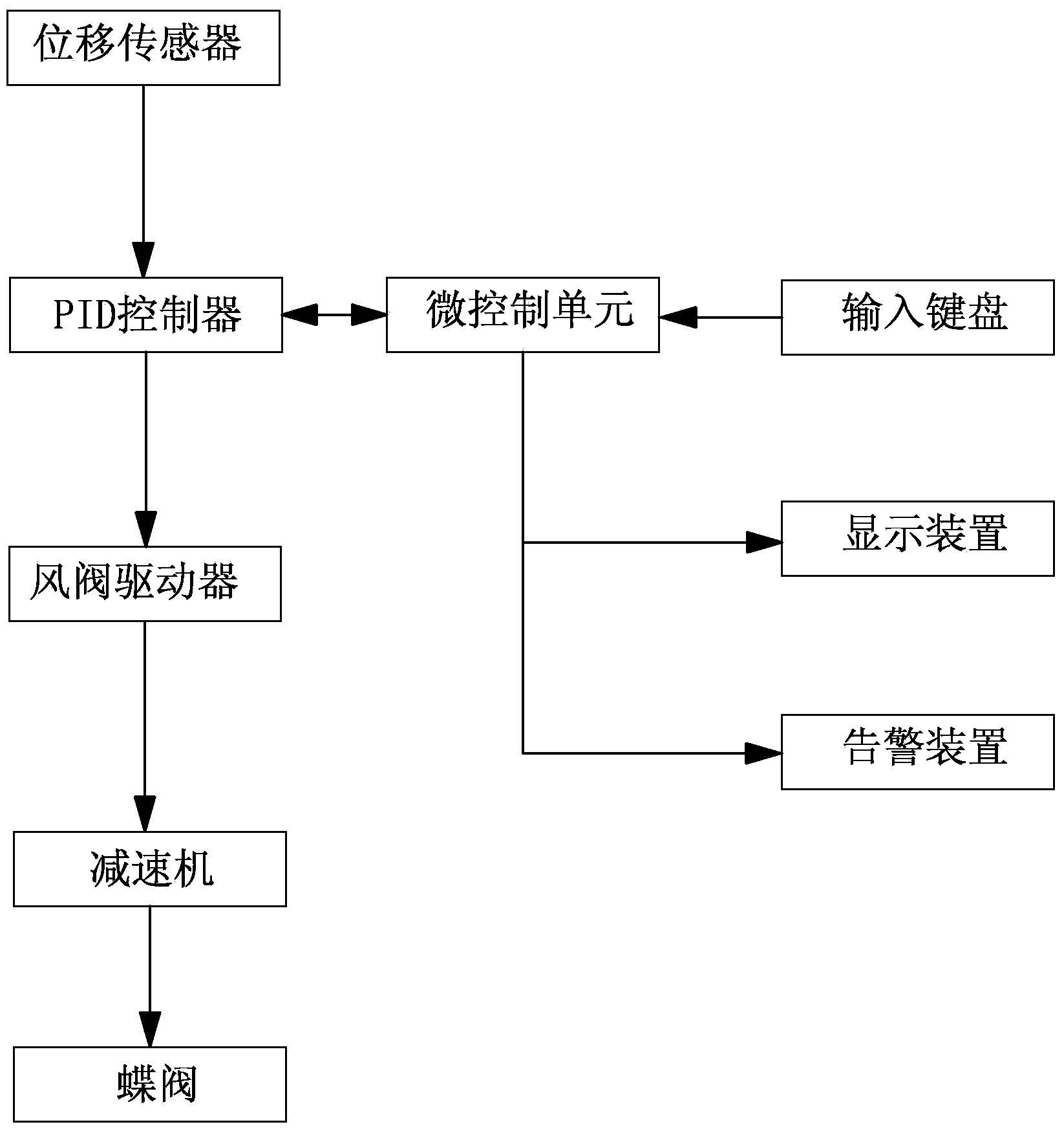

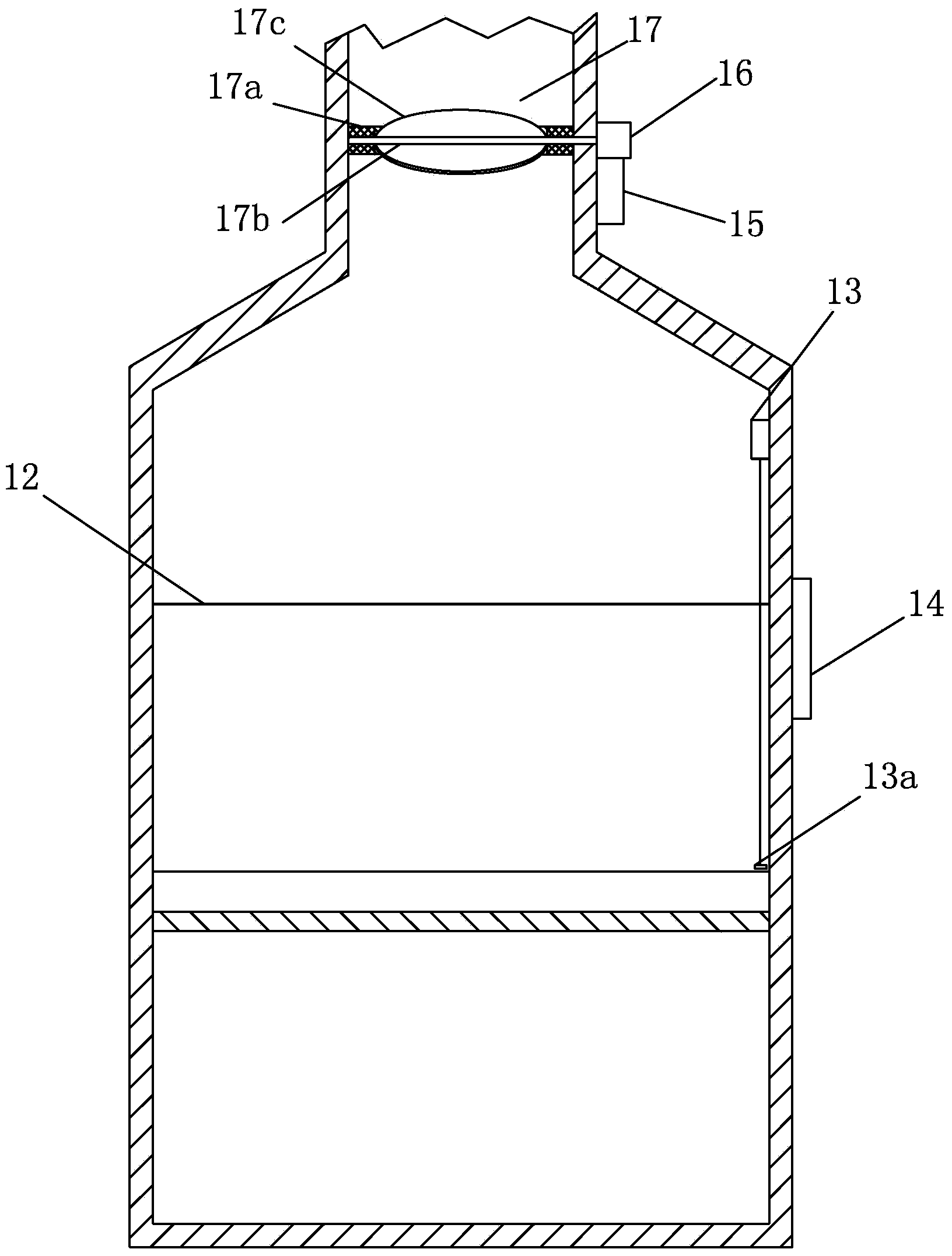

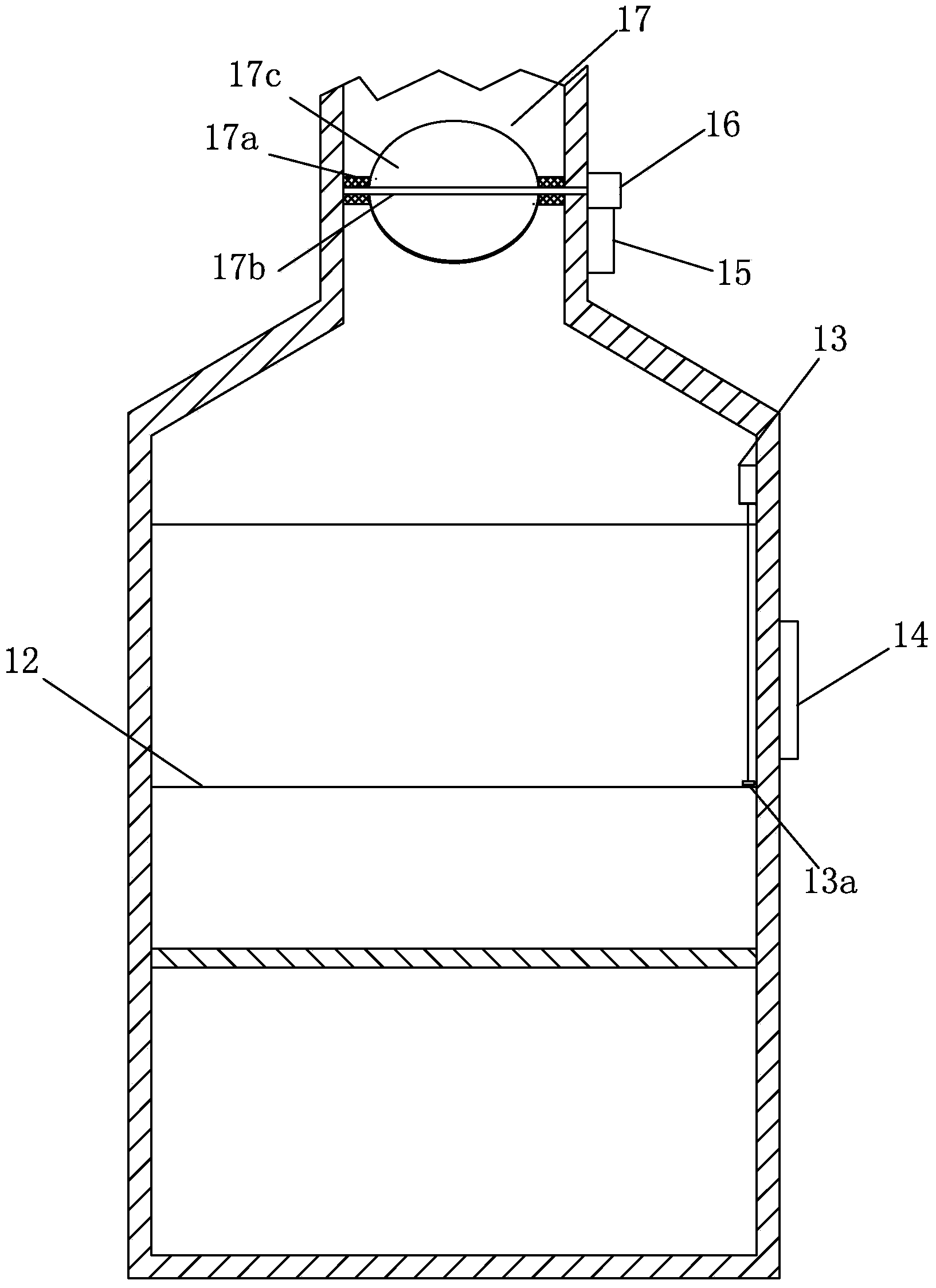

[0034] The wind speed control system on the surface of the fume hood of the present invention uses the sensor to sample the opening height of the window on the surface of the cabinet, converts the height information into a corresponding electrical signal and transmits it to the signal controller, and the signal controller compares the electrical signal with the preset threshold data , which is converted into the control signal of the air valve driver. According to the control signal, the air valve driver drives the valve stem of the butterfly valve in the exhaust duct to rotate, drives the angle of the butterfly plate to change, and then changes the exhaust air volume in the exhaust duct to realize the control according to the window on the cabinet surface. The open area, adjust the cabinet wind speed.

[0035] Such as figure 1 As shown, this embodiment includes a displacement sensor, a PID controller (proportional-integral-derivative controller), a damper driver, a reducer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com