Accurate cutting and punching jump-scrap prevention mechanism

An anti-jumping and precision cutting technology, applied in the direction of perforation tools, metal processing equipment, manufacturing tools, etc., can solve the problems of material jumping, product indentation, template cracking, etc., to optimize the structure, prevent material jumping, save The effect of large cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

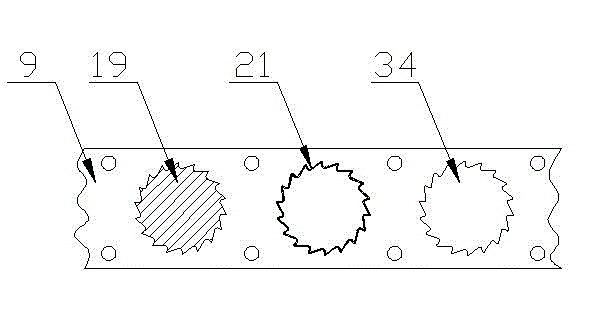

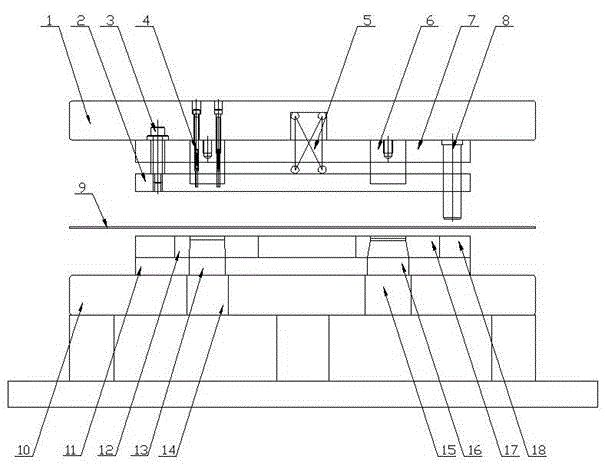

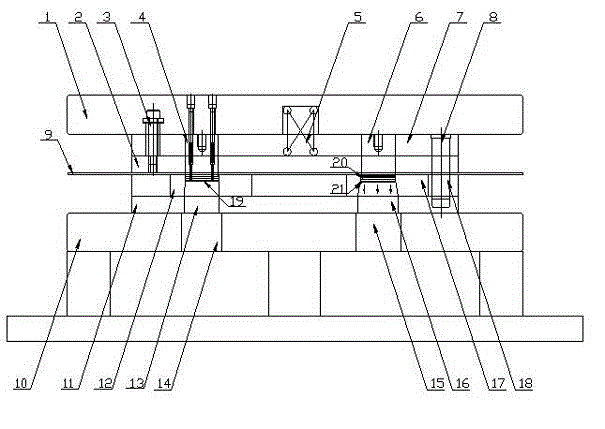

[0036] figure 1 It is a sample layout diagram of precision cutting, punching and anti-jumping of the product according to an embodiment of the present invention; figure 2 It is a side view of an embodiment of the present invention in the mold opening state; image 3 It is a side view of an embodiment of the present invention in a closed mold state.

[0037] Such as Figure 1-Figure 3 Shown: fine cutting punching anti-jumping mechanism, the stamping die includes an upper die and a lower die, the upper die includes an upper die base 1, an upper splint 7 and a stripping plate 2 arranged sequentially from top to bottom, the The lower mold includes a lower template 18, a lower backing plate 11 and a lower mold base 10 arranged in sequence from top to bottom, and the said upper mold is provided with contour bolts 3, springs 5 and inner gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com