Cold-core-box-method epoxy resin single-component binder, cast mixture and cast molding body

A method of epoxy resin, epoxy resin technology, applied in the direction of casting molding equipment, casting mold, core, etc., can solve the problems of scarring scrap rate, sand washing and sand inclusion, low thermal strength, etc., and achieve remarkable casting quality , Reduction of scrap rate, low viscosity effect

Active Publication Date: 2012-10-10

JINAN SHENGQUAN GROUP SHARE HLDG

View PDF10 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When used in steel castings, the low thermal strength is likely to produce sand

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

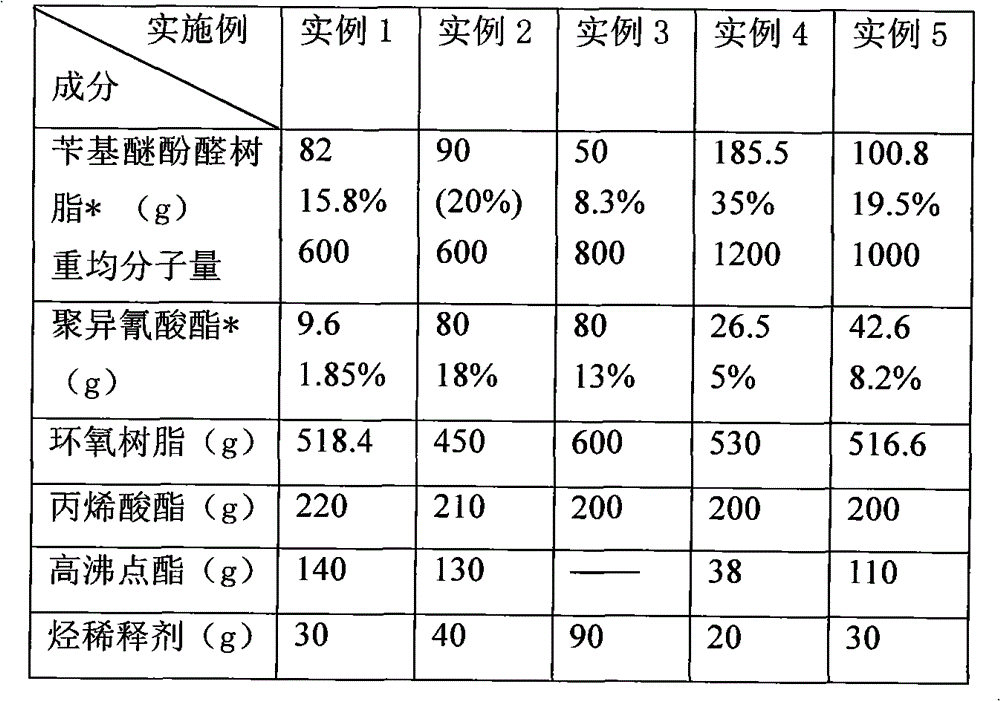

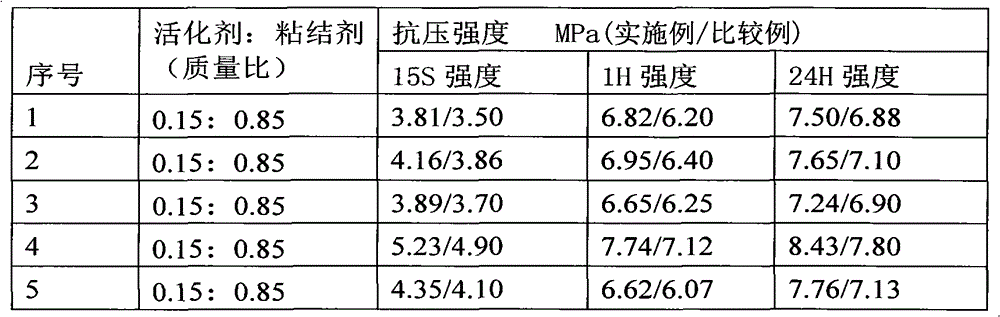

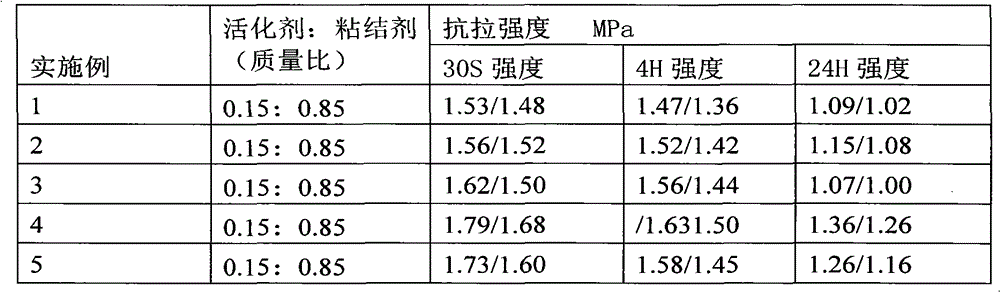

The invention discloses a cold-core-box-method epoxy resin single-component binder which is used for sulfur dioxide blowing solidification in the absence of an organic peroxide activating agent. The binder comprises by weight (a) 1 part to 40 parts of benzyl ether phenolic resin, (b) 0.1 part to 10 parts of polyisocyanate, (c) 40-77 parts of epoxy resin, (d) 10-30 parts of acrylate and (e) 1 part to 30 parts of high-boiling-point ester and/or hydrocarbon diluent. The weight-average molecular weight of the benzyl ether phenolic resin is between 500 and 2000. The binder overcomes the shortcoming in the prior art that the binder for sulfur dioxide blowing solidification is poor in fragility and humidity resistance, improves strength of sand cores and sand types in the casing process, simultaneously reduces viscosity, and is favorable for the casting process.

Description

Technical field [0001] The invention relates to a binder. The binder is used for casting resin sand mixture, blowing gaseous sulfur dioxide to solidify, forming a core mold for manufacturing cast metal castings, and is suitable for various types of cast steel, cast iron and non-ferrous alloy parts in the field of casting . Background technique [0002] In the foundry industry, the cold box method refers to a process that uses gas or aerosol catalysts to catalyze resin sand at room temperature to achieve rapid curing. According to different gas or aerosol catalysts, the cold box method can be divided into amine method, SO2 method, CO2 resin method and methyl formate method. [0003] The French SPAIC company invented the SO2-furan resin method in 1971, called the Hardox method, and used it in casting production in 1975. The technological process is: adding peroxide-containing activator to the core sand, when SO2 passes through the core sand, it combines with the new ecological oxyg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22C1/22

Inventor 祝建勋许增彬

Owner JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com