Automatic spiral hole milling device and method

A helical hole milling and automatic technology, applied in the direction of automatic control device, driving device, feeding device, etc., can solve the problems of heavy machine weight, complex structure, low degree of automation, etc., to simplify the structure and reduce the weight of the whole machine , the effect of improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The automatic screw hole making device and method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

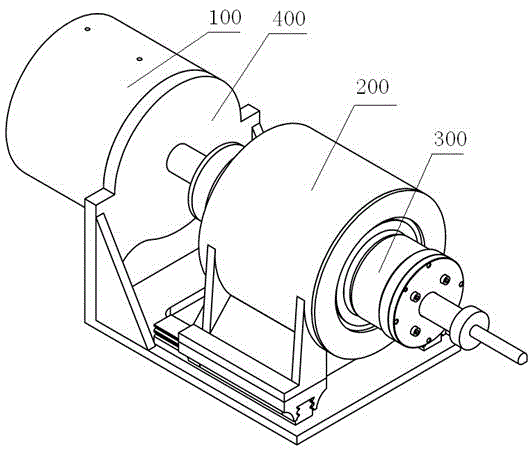

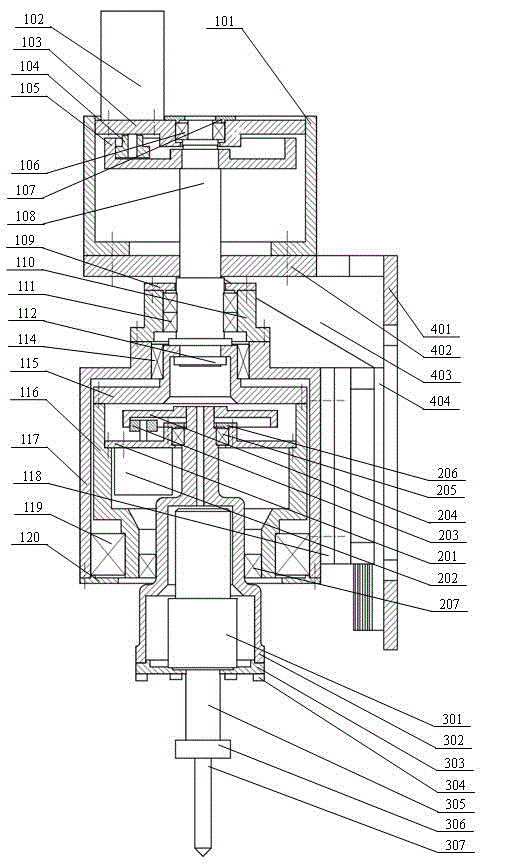

[0031] figure 1 and figure 2 Shown is an automatic helical milling device for a large workpiece porous system disclosed by the present invention. The device mainly includes an L-shaped combined bracket 400, a screw feed mechanism 100 arranged on the combined bracket 400, and a screw mounted on the screw. The revolution radius adjustment mechanism 200 inside the feed mechanism 100, the tool rotation speed regulation mechanism 300;

[0032] The combined bracket 400 includes a bottom plate 401 in the horizontal direction, a back plate 402 in the vertical direction, and two right-angled triangle reinforcing plates 403. axial sides;

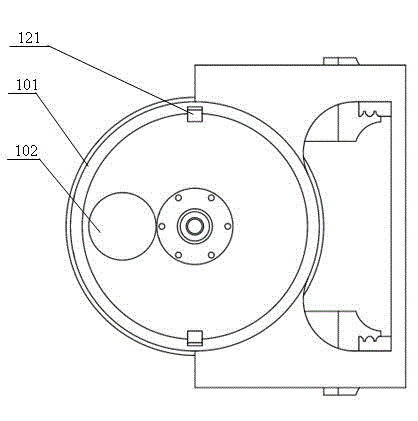

[0033]The screw feed mechanism 100 includes an axial feed housing 117, a support cylinder 101, and an axial slide block 103 and a screw mandrel 108...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com