Automobile seat transporting and conveying system

A conveying system and car seat technology, applied in conveyors, conveyor objects, mechanical conveyors, etc., to achieve stable performance, ensure smooth movement, and eliminate the need for secondary handling and packaging operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

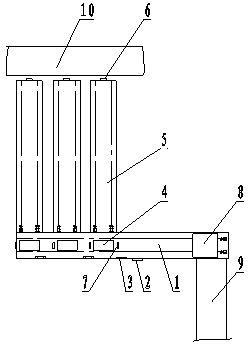

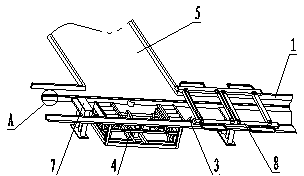

[0022] Referring to Fig. 1, the present invention comprises conveying track 1, steering mechanism 4, storage delivery goods lane 5, seat tray 8 and PLC control system, and described delivery track 1 front end is connected with seat production line 9, and described storage delivery goods lane 5 The end is connected to the logistics channel 10, the number of the steering mechanism 4 and the storage delivery lane 5 matches the type of the seat, the steering mechanism 4 is arranged at the junction of the conveying track 1 and the storage delivery lane 5, and the seat tray 8 slides on the delivery track 1, and can enter the storage delivery lane 5 through the steering mechanism 4, and seat products are placed on the seat tray 8.

[0023] Referring to Fig. 5, the steering mechanism 4 of the present invention includes a steering drive part, a lifting control unit and a base 4-1, and the steering drive part is composed of a motor 4-4 and a transmission unit 4-5, and the transmission un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com