Lubricating oil

A technology for lubricating oil and base oil, which is applied in the field of lubricating oil to reduce the difficulty of low-temperature startup, facilitate unified management, and effectively utilize resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Contains 82.5 wt% base oil and 15.5 wt% viscosity index improver, wherein the kinematic viscosity of the lubricating oil at 40°C is 68 mm 2 / s, kinematic viscosity at 100°C is 13 mm 2 / s.

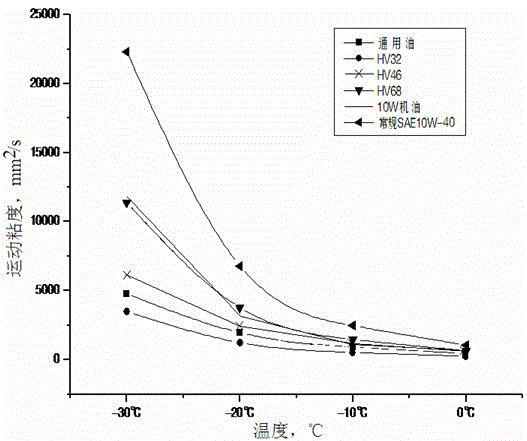

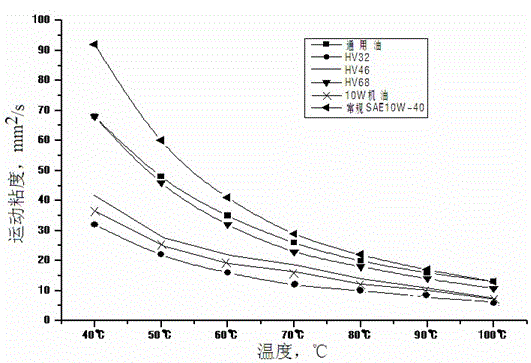

[0039] Such as figure 1 The low temperature viscosity curves of the universal oil and HV32, HV46, HV68 No. hydraulic oil, 10W engine oil, conventional SAE 10W-40 shown in the embodiment of the present invention, and figure 2 The high-temperature viscosity curves of the general-purpose oil of the present invention shown in the embodiment of the present invention and HV32, HV46, HV68 hydraulic oil, 10W machine oil, and conventional SAE 10W-40, wherein, HV32, HV46, HV68, that is, VG32, VG46, VG68 hydraulic oil The viscosity index of the oil is 150, the viscosity index of 10W engine oil is 114, and the viscosity index of SAE 10W-40 engine oil is 140. The general oil of this embodiment, that is, the lubricating oil can meet the requirements of diesel engine oil and hydraulic oil VG qu...

Embodiment 2

[0041] Including 79.5 wt% base oil and 18.5 wt% viscosity index improver, wherein the kinematic viscosity of the lubricating oil at 40°C is 70 mm 2 / s, kinematic viscosity at 100°C is 14 mm 2 / s. It meets the requirements of diesel engine oil and hydraulic oil VG quality grade, and the application temperature range covers VG32, VG46, VG68 hydraulic oil standard oil and diesel engine oil.

Embodiment 3

[0043] Contains 84 wt% base oil and 15.5 wt% viscosity index improver, wherein the kinematic viscosity of the lubricating oil at 40°C is 69 mm 2 / s, kinematic viscosity at 100°C is 12 mm 2 / s. It meets the requirements of diesel engine oil and hydraulic oil VG quality grade, and the application temperature range covers VG32, VG46, VG68 hydraulic oil standard oil and diesel engine oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com