Limit-specification IF steel and furnace zone through plate method thereof

A technology with extreme specifications and through-board, applied in furnaces, heat treatment furnaces, furnace types, etc., it can solve the problems that the shape quality of the annealed plate cannot meet the needs of customers, the occurrence of high temperature buckling, and the impact of production rhythm, etc., to improve the quality of annealed shape. , Reduce the temperature difference of the roller body, and achieve the effect of stable passing through the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

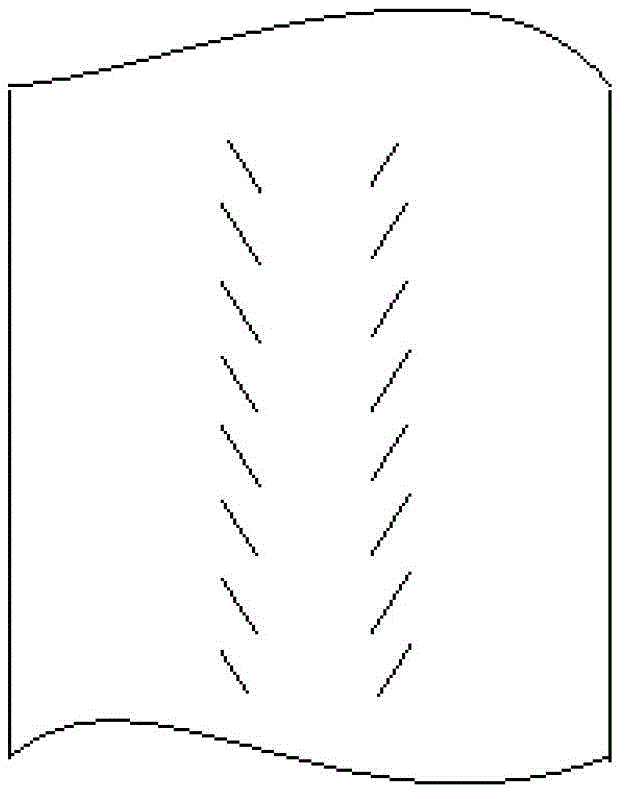

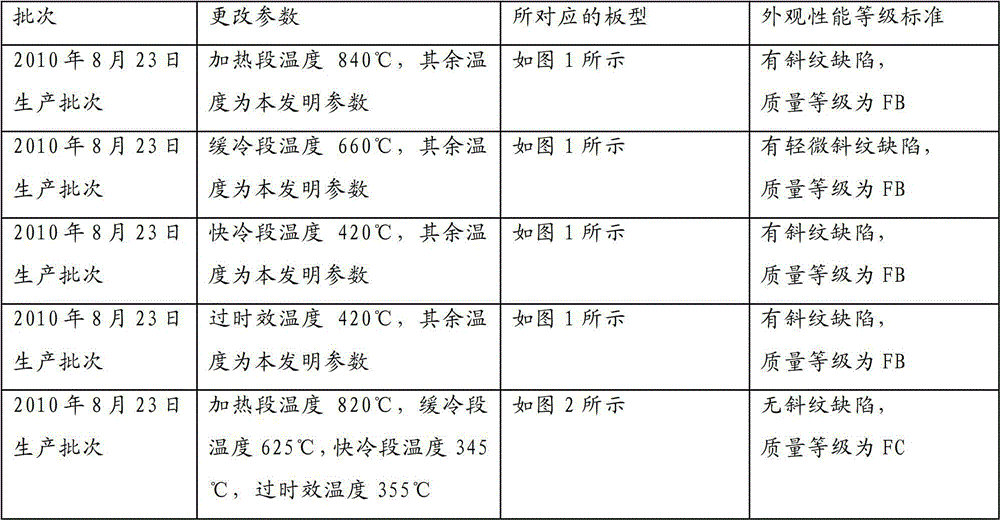

Image

Examples

Embodiment Construction

[0015] The present invention provides a method for passing plates in the furnace area of limit specification IF steel, the composition of which is: C≤0.0015, Si≤0.03, Mn: 0.1-0.14, P≤0.01, S≤0.01, Alt: 0.02- 0.045, Ti: 0.06-0.08, N≤0.004, balance: Fe.

[0016] By doing the following specific action points:

[0017] 1. First confirm the production plan. The annealing temperature, thickness, and width transitions of thin and wide materials should be as small as possible. Concentrate production scheduling and production of thin and wide automotive sheets as much as possible, and do not produce thin and wide sheets under the condition that continuous transitions lead to unstable furnace conditions.

[0018] 2. Before thin and wide materials enter the furnace, the rolls should be changed in advance when transitioning from narrow to wide. When the working rolls are chrome-plated, the rolls can be changed 20 kilometers in advance to create a stable furnace condition to ensure smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com