Intelligent warp knitting multi-speed electronic let-off system

An electronic let-off and intelligent technology, applied in the field of knitting machinery, can solve problems such as insufficient intelligence and unsatisfactory effect, meet system control requirements, meet multi-speed, high-precision, high-speed frequent switching, and improve rapid response capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

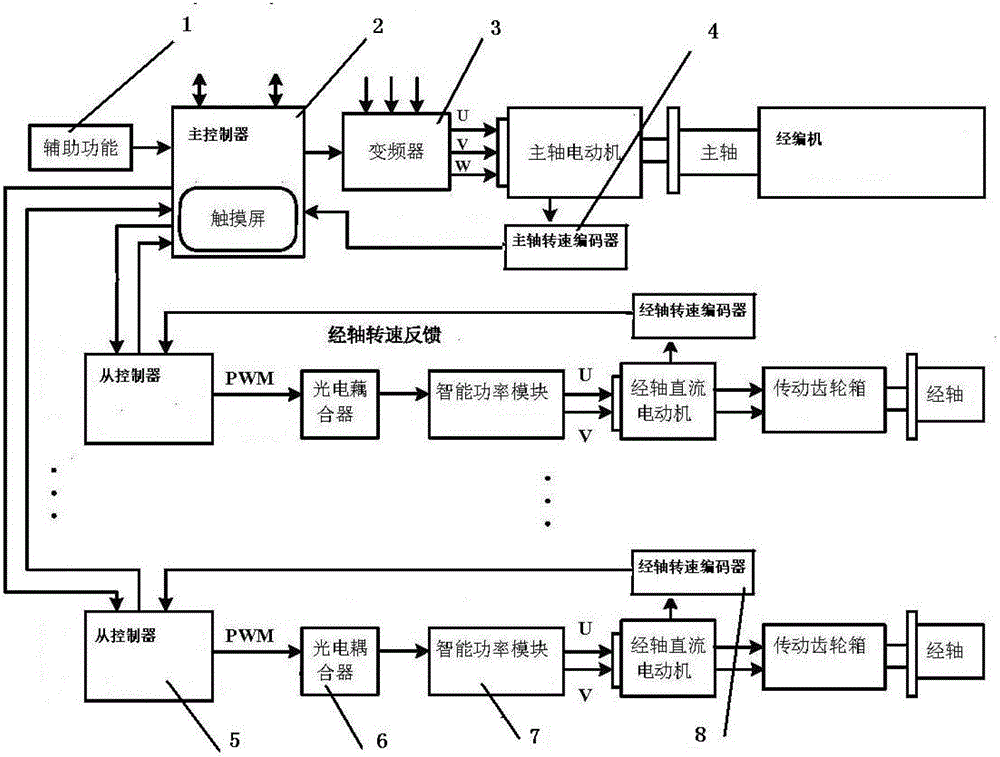

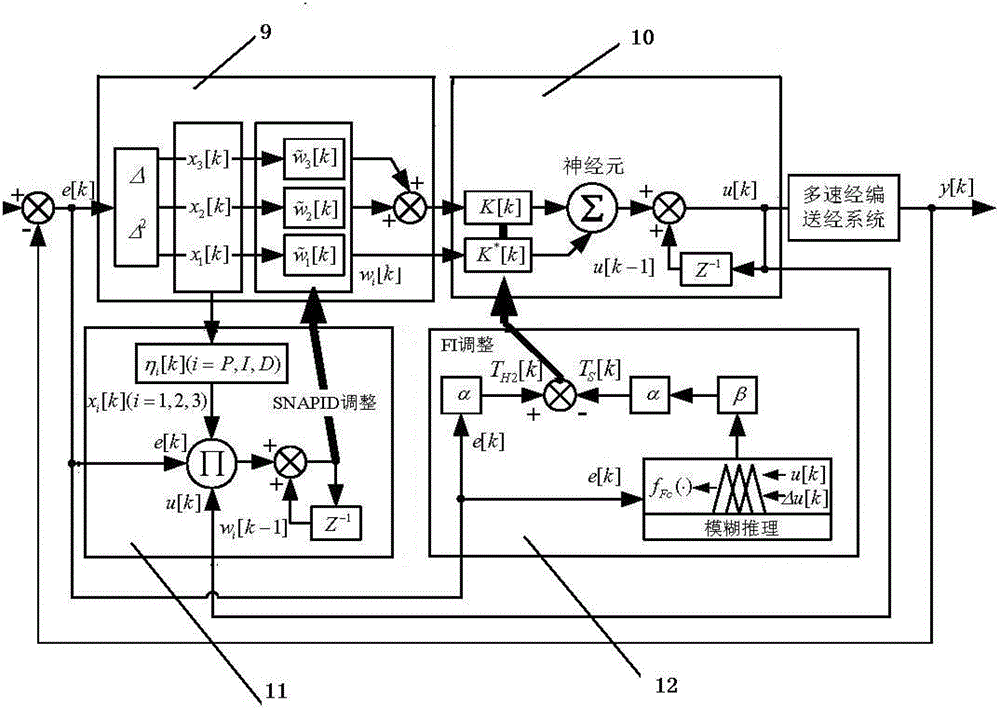

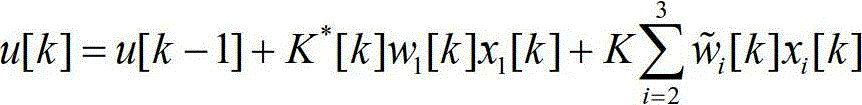

[0025] Embodiments of the present invention, such as figure 1 , figure 2 As shown, the intelligent warp knitting multi-speed electronic warp let-off system includes a digital PID master controller 2 connected with a parameter setting input device, a frequency converter 3, a spindle speed encoder 4 set on the spindle motor, and a spindle speed encoder 4 set on the warp beam motor. The warp beam speed encoder 8 on the top; the main controller 2 is driven and connected to the main shaft motor through the frequency converter 3, and the output end of the main shaft speed encoder 4 is electrically connected with a feedback input end of the main controller 2. It is characterized in that: it also includes Digital warp beam slave controller 5, said slave controller 5 is a digital PID controller connected by multiple groups of parallel feedbacks, the slave controller 5 includes a PID module, a single neuron adaptive algorithm module 11 and a fuzzy immune optimization algorithm module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com