Micropulsation combustor

A technology of micro burner and pulsation combustion, which is applied in the direction of burner, gas fuel burner, combustion method, etc., to achieve the effect of short time, high energy density and stable position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

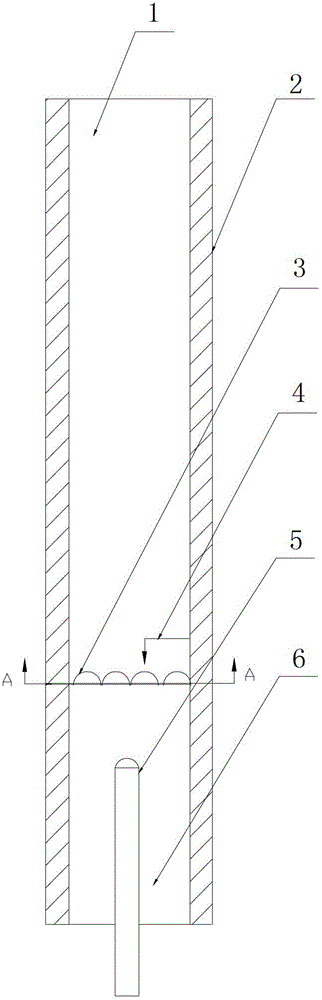

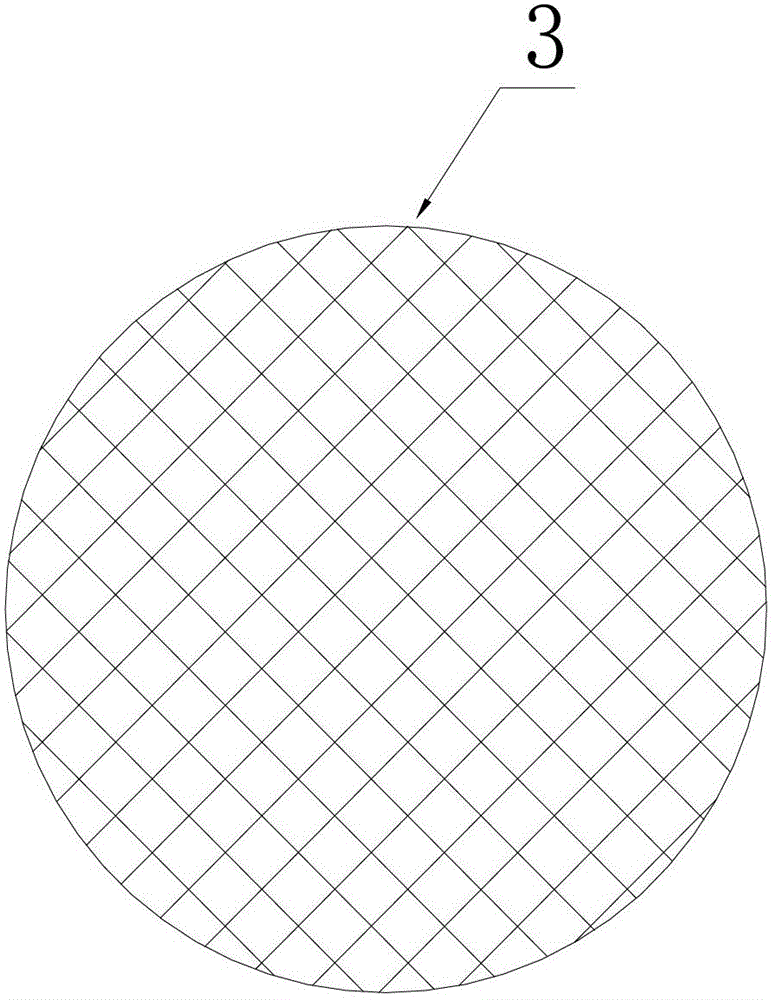

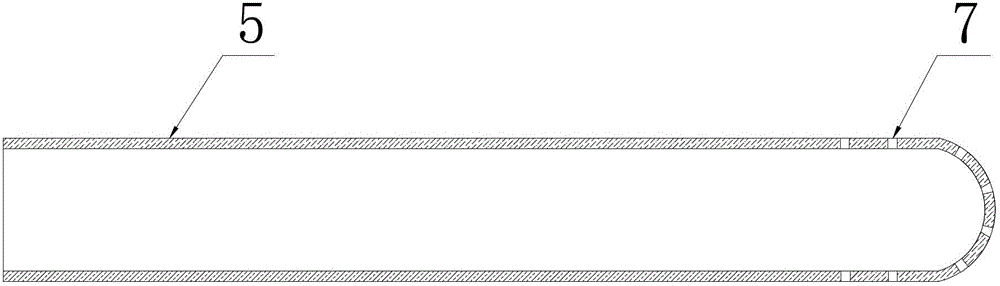

[0022] A micro-pulse burner, characterized in that it consists of a micro-burner 2, a gas inlet pipe 5, a platinum metal fiber mesh 3 and a high-voltage electrode igniter 4, the micro-burner is a high-temperature-resistant hollow circular tube, and the micro-burner is made of Hollow round tubes made of stainless steel, quartz or ceramic materials. Its lower end is a gas inlet 6, and its upper end is a gas outlet 1. When in use, it is placed vertically. The inner diameter of the micro burner is 10-14 mm, the wall thickness is 1.5-2.1 mm, the length is 20-30 cm, and the aspect ratio of the micro burner is 20-30. The microburner tube preferably has an inner diameter of 12 mm, a wall thickness of 1.8 mm, and an overall length of 25 cm. The pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com