Hydraulic ventilation energy-saving cooling tower with intelligent compensation device

A compensation device and ventilated technology, which is applied in the field of hydraulic ventilated energy-saving cooling towers, can solve the problems of low efficiency, thermal performance of cooling towers that cannot meet the requirements of the process, and high energy consumption, so as to achieve high cooling efficiency and save hydraulic kinetic energy , the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

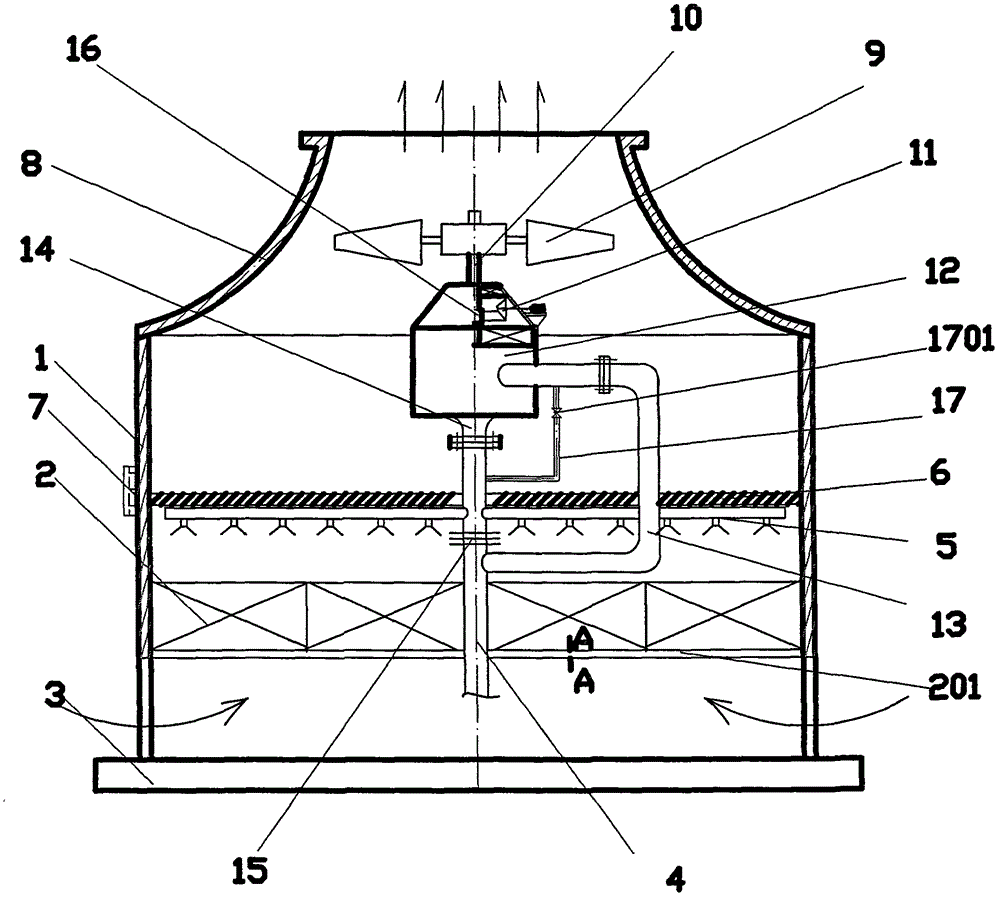

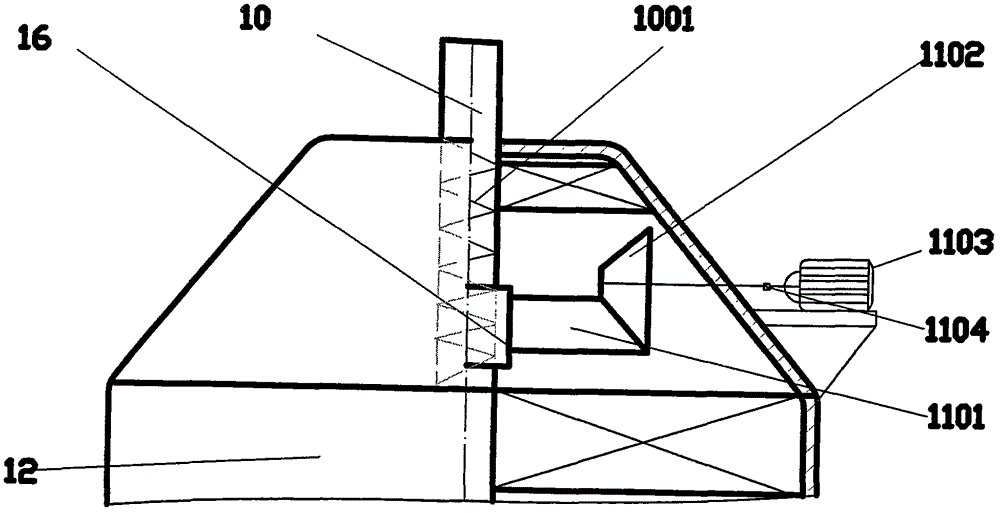

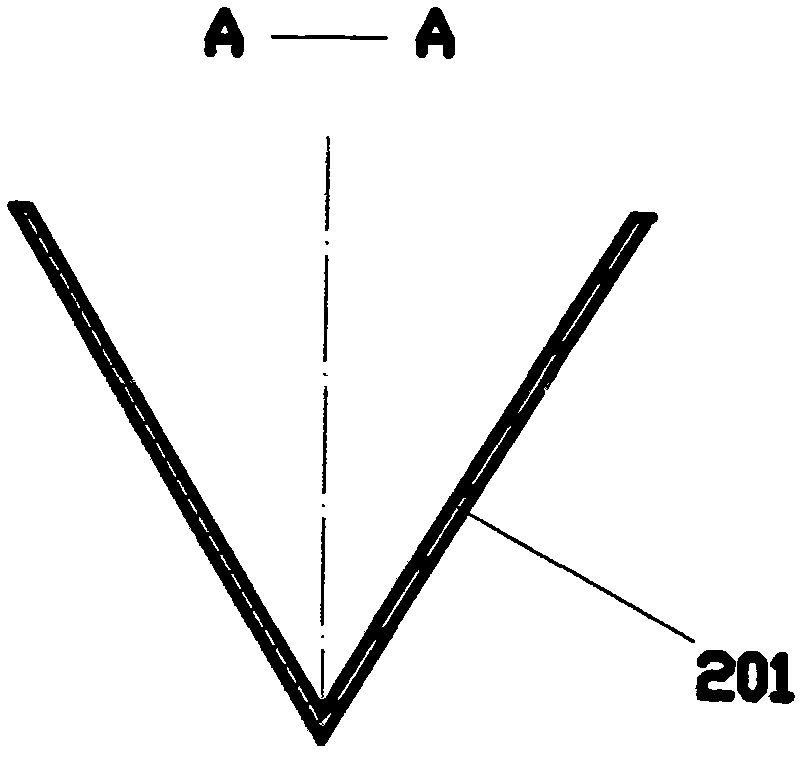

Embodiment 1

[0021] A hydraulic ventilated energy-saving cooling tower with an intelligent compensation device, comprising: an automatic controller, a water spraying filler 2 arranged inside the tower body 1, a water collection pool 3 arranged under the tower body 1, a water eliminator 6 and a water distribution spray device arranged inside the tower 5. The water distribution and spraying device 5 is connected to the tower water pipe 4, and the fan 9 is arranged in the air cylinder 8 at the top of the tower body 1. The tower water pipe 4 is connected to the hydraulic propeller 12 through the hydraulic propeller water inlet pipe 13, and the hydraulic propeller The water inlet pipe communicates with the hydraulic propeller decompression device 17, and the hydraulic propeller decompression device 17 communicates with the hydraulic propeller outlet pipe 14 through a pressure reducing valve 1701; the impeller output shaft 10 of the hydraulic propeller 12 is connected to the blower fan 9, and it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com