Three-dimensional mirror object shape measurement system based on sinusoidal stripe projection

A technology of sinusoidal fringes and measuring systems, which is applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems that the measurement accuracy cannot meet the high-precision requirements, the equipment is expensive, and the measurement range is small, so as to achieve online three-dimensional detection, structural Simple, anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

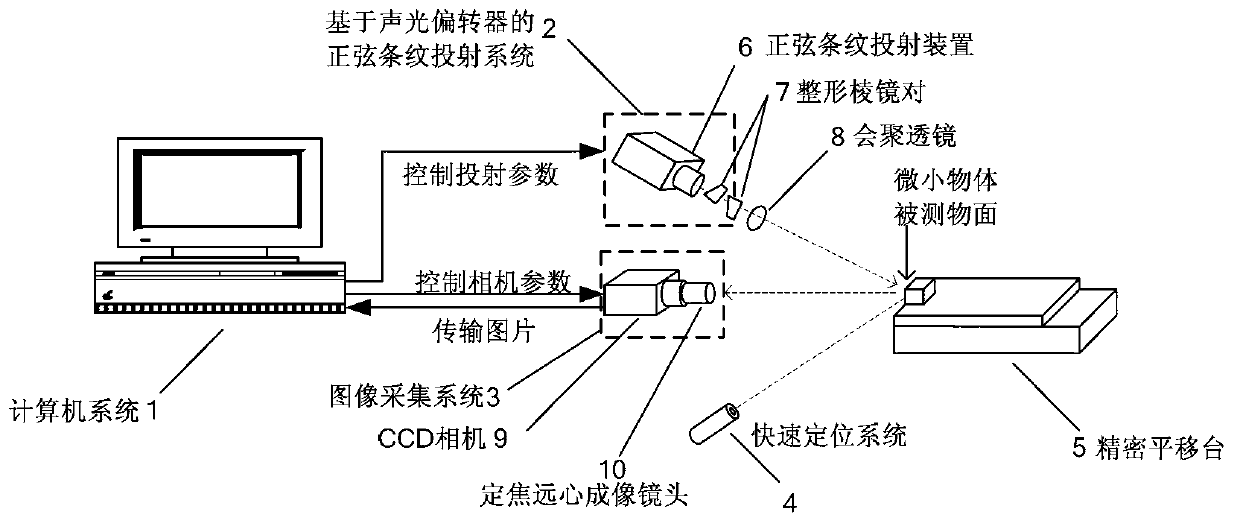

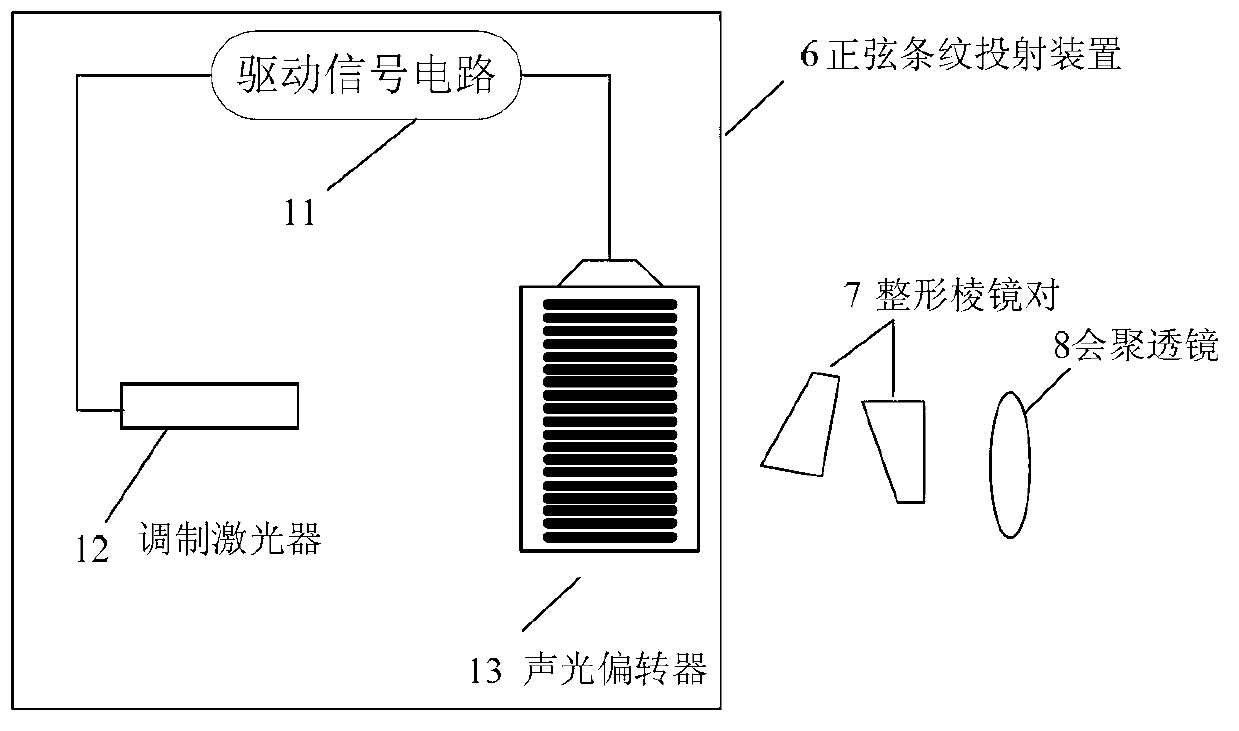

[0033] Such as figure 1 As shown, the present invention is based on a sinusoidal fringe projection-based mirror object three-dimensional shape measurement system, which consists of a computer system 1, a sinusoidal fringe projection system 2 based on an acousto-optic deflector, an image acquisition system 3, a fast positioning system 4, and a precision translation stage 5 composition. The position connection relationship between them is: the sinusoidal fringe projection system 2 based on the acousto-optic deflector is connected to the computer system 1 through the serial port data transmission line, and is controlled by the computer system 1 to tilt towards the measured surface of the mirror object on the precision translation stage 5 Sine stripes are projected at 45°; the image acquisition system 3 is connected to the computer system 1 through a super five-category network cable, and the position of the image acquisition system 3 is adjusted so that the focal plane of the obj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

| Focal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com