Ultrasonic flaw detection method of weld joint at U-shaped angle of rib of steel bridge plate unit

A technology of ultrasonic flaw detection and bridge plate, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, etc. It can solve problems such as reflected wave interference, unfavorable ultrasonic detection judgment, and difficulty in ultrasonic detection, so as to ensure manufacturing quality and improve work responsibility. Effect of improving fatigue strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the technical solution of the present invention in detail through a best embodiment in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the embodiment.

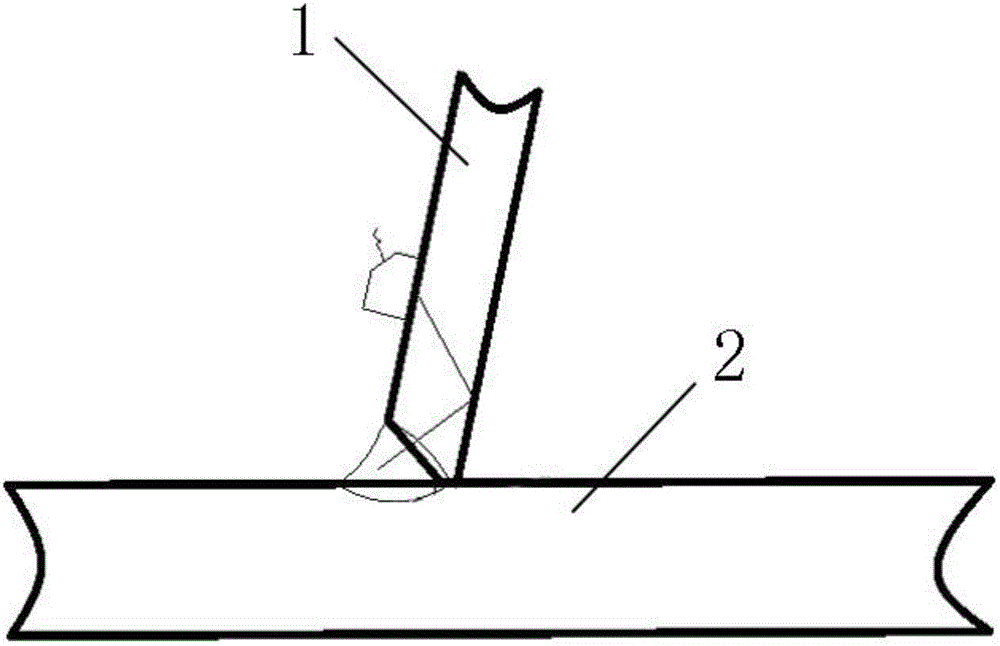

[0021] like figure 1 As shown, the U-rib fillet weld connects the U-rib surface 1 and the bottom plate 2, the thickness of the U-rib is 8mm, and the angle between the U-rib surface 1 and the bottom plate 2 is greater than 90°.

[0022] An ultrasonic flaw detection method for U-rib fillet welds of steel bridge plate units, comprising the steps of:

[0023] Weld defect detection:

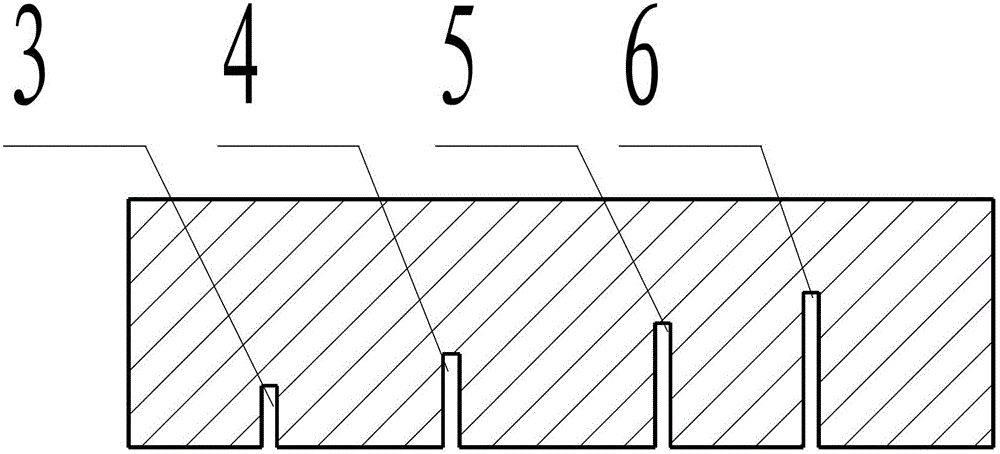

[0024] U rib plate surface 1 is used as the detection surface, RB-2 test block is used as the reference sensitivity calibration test block, and a 2.5~5MHz, K1.5 oblique probe is used for detection;

[0025] The distance amplitude curve and sensitivity are: waste judgment line Φ3×40-4dB, quantitative line Φ3×40-10dB, evaluation line Φ3×40-16dB;

[0026] We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com