Oscillation testing device of servo motor of numerical control machine tool

A test device and servo motor technology, applied in the mechanical field, can solve problems such as difficult to judge, not obvious vibration, motor vibration, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

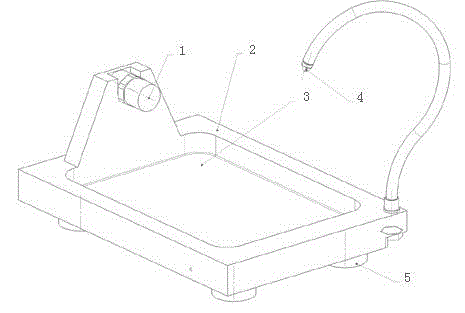

[0025] The following is attached figure 1 An embodiment of the invention is described:

[0026] The test tool body 2 is equipped with an acceleration sensor 1 and a shallow pool 3. A layer of 20# engine oil is placed in the shallow pool 3. The adjustable camera 4 is facing the liquid surface. The height is just enough to take a picture of the liquid surface. The magnetic base 5 is used under the test tool body to form a stable connection with the working platform of the machine tool, and it moves with the feed movement of the working platform of the machine tool.

[0027] When the CNC machine tool is started, the liquid level fluctuation of 20# engine oil captured by the adjustable camera 4 is transmitted to the computer for observation, and it is judged whether it is the vibration of the servo motor. If it is confirmed that the vibration is caused by the vibration of the servo motor, the acceleration The time-domain and frequency-domain signals tested by sensor 1 are analyz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com