Efficient motor stator for washing machine

A technology for motor stator and washing machine, which is applied to the static parts of the magnetic circuit, the shape/pattern/structure of the magnetic circuit, etc., can solve the problem that the stator punching structure is not ideal, the magnetic density of the stator teeth and the forehead is high, and the production cost of the motor is increased. and other problems, to achieve the effect of being conducive to market competition, less iron consumption, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

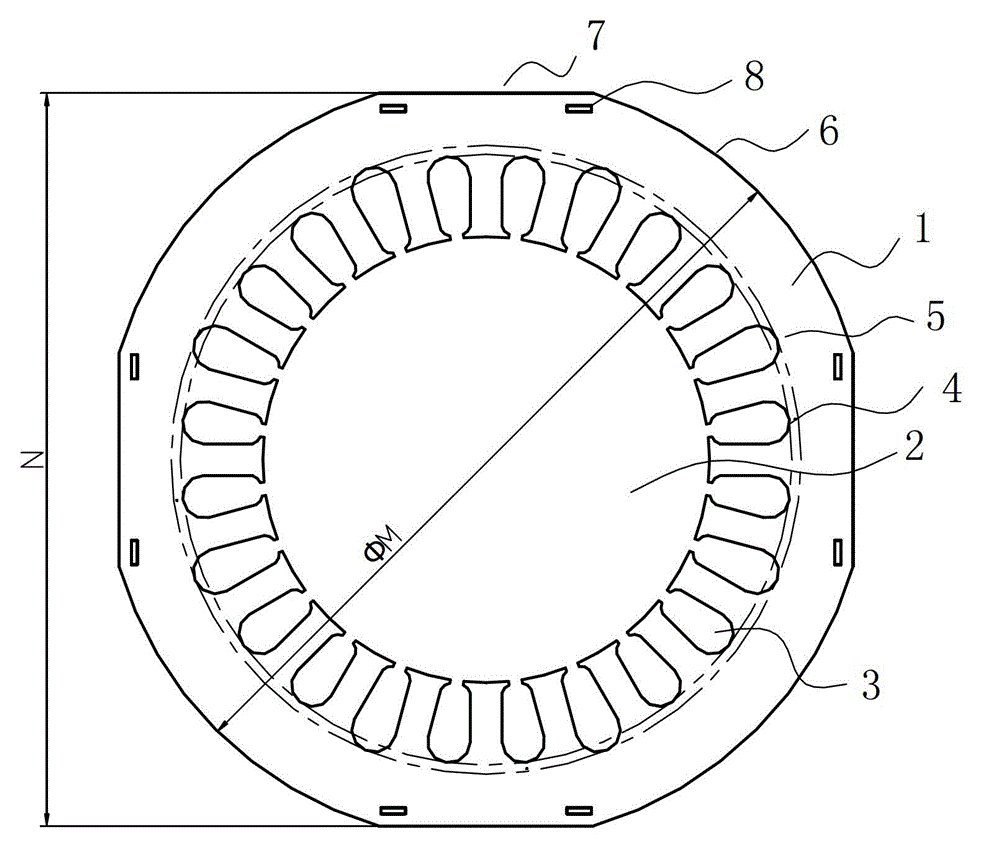

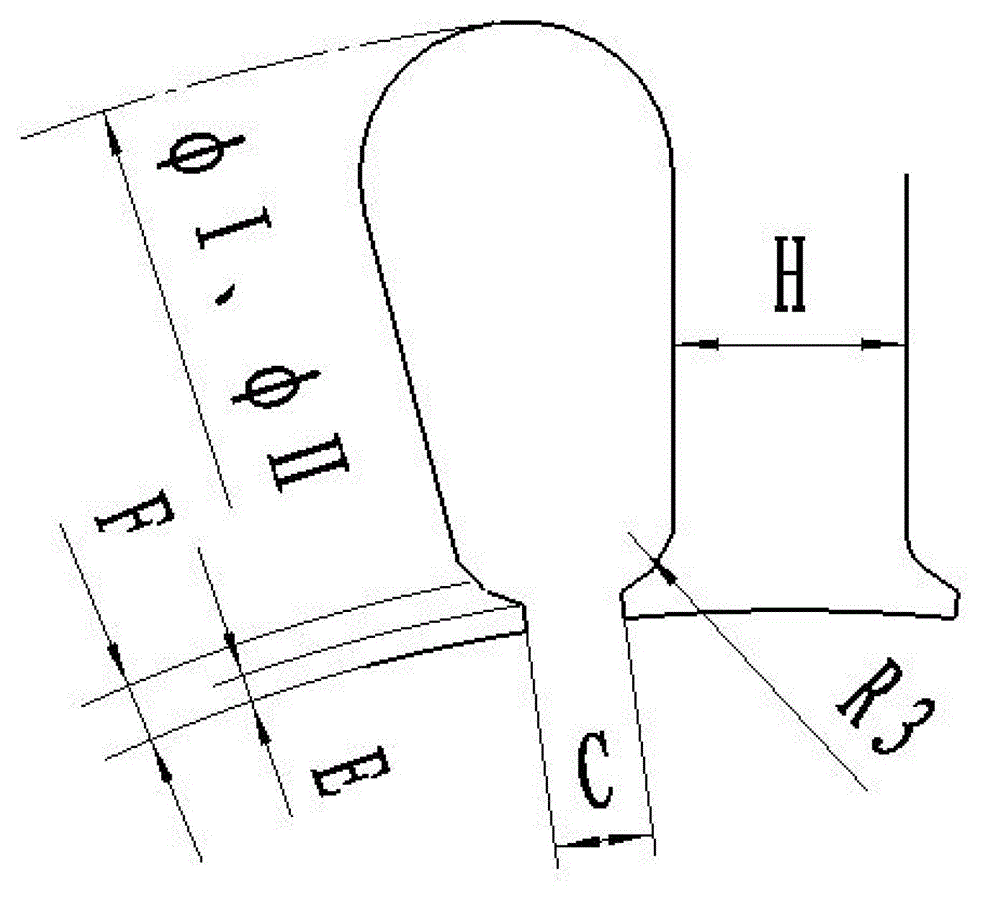

[0018] Embodiment 1: High-efficiency washing machine motor stator, as attached figure 1 As shown, the stator is formed by superimposing punching sheets 1, the middle part of the punching sheet 1 is provided with a hollow inner circular hole 2, and 24 punching slots 3 are uniformly opened in the radial direction of the hollow inner circular hole 2, and the punching slots The shape of 3 includes round-bottomed grooves, pear-shaped grooves or trapezoidal grooves; the punching groove 3 includes 16 shallow grooves I4 and 8 deep grooves II5, and the opening rules can be 2 shallow grooves I and 1 Deep groove II interval setting. The outer surface of the punching sheet 1 is spaced apart with a round edge M6 and a trimming edge N7, the size of the round edge M6 is diameter ΦM=120mm, and the length of the trimming edge N7 is N=125mm; the size of the hollow inner circular hole 2 It is diameter Φ75mm; the size of the circle where the groove top of the shallow groove I4 of the punching gr...

Embodiment 2

[0019] Example 2: Efficient washing machine motor stator, as attached figure 1 As shown, the stator is formed by superimposing punching sheets 1, the middle part of the punching sheet 1 is provided with a hollow inner circular hole 2, and 24 punching slots 3 are uniformly opened in the radial direction of the hollow inner circular hole 2, and the punching slots The shape of 3 includes round-bottomed grooves, pear-shaped grooves or trapezoidal grooves; the punching groove 3 includes 16 shallow grooves I4 and 8 deep grooves II5, and the opening rules can be 2 shallow grooves I and 1 Deep groove II interval setting. The outer surface of the punching sheet 1 is separated by a round edge M6 and a trimming edge N7, the size of the round edge M6 is diameter ΦM=130mm, and the length of the trimming edge N7 is N=115mm; the size of the hollow inner hole 2 It is a diameter of Φ68mm; the size of the circle where the groove top of the shallow groove I4 of the punching groove 3 is Φ101mm, ...

Embodiment 3

[0020] Embodiment 3 of the present invention: efficient washing machine motor stator, as attached figure 1 As shown, the stator is formed by superimposing punching sheets 1, the middle part of the punching sheet 1 is provided with a hollow inner circular hole 2, and 24 punching slots 3 are uniformly opened in the radial direction of the hollow inner circular hole 2, and the punching slots The shape of 3 includes round-bottomed grooves, pear-shaped grooves or trapezoidal grooves; the punching groove 3 includes 16 shallow grooves I4 and 8 deep grooves II5, and the opening rules can be 2 shallow grooves I and 1 Deep groove II interval setting. The outer surface of the punching sheet 1 is separated by a round edge M6 and a trimming edge N7, the size of the round edge M6 is diameter ΦM=125mm, and the length of the trimming edge N7 is N=120mm; the size of the hollow inner circular hole 2 It is a diameter of Φ70mm; the size of the circle where the groove top of the shallow groove I4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com