Control device for vehicle driving device

A technology of a driving device and a control device, which is applied to the arrangement of a plurality of different prime movers of a control device and a general power device, a transmission device, etc., can solve the problems of energy consumption and heat generation of the motor, so as to prevent damage and restrain the driving wheel. the slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

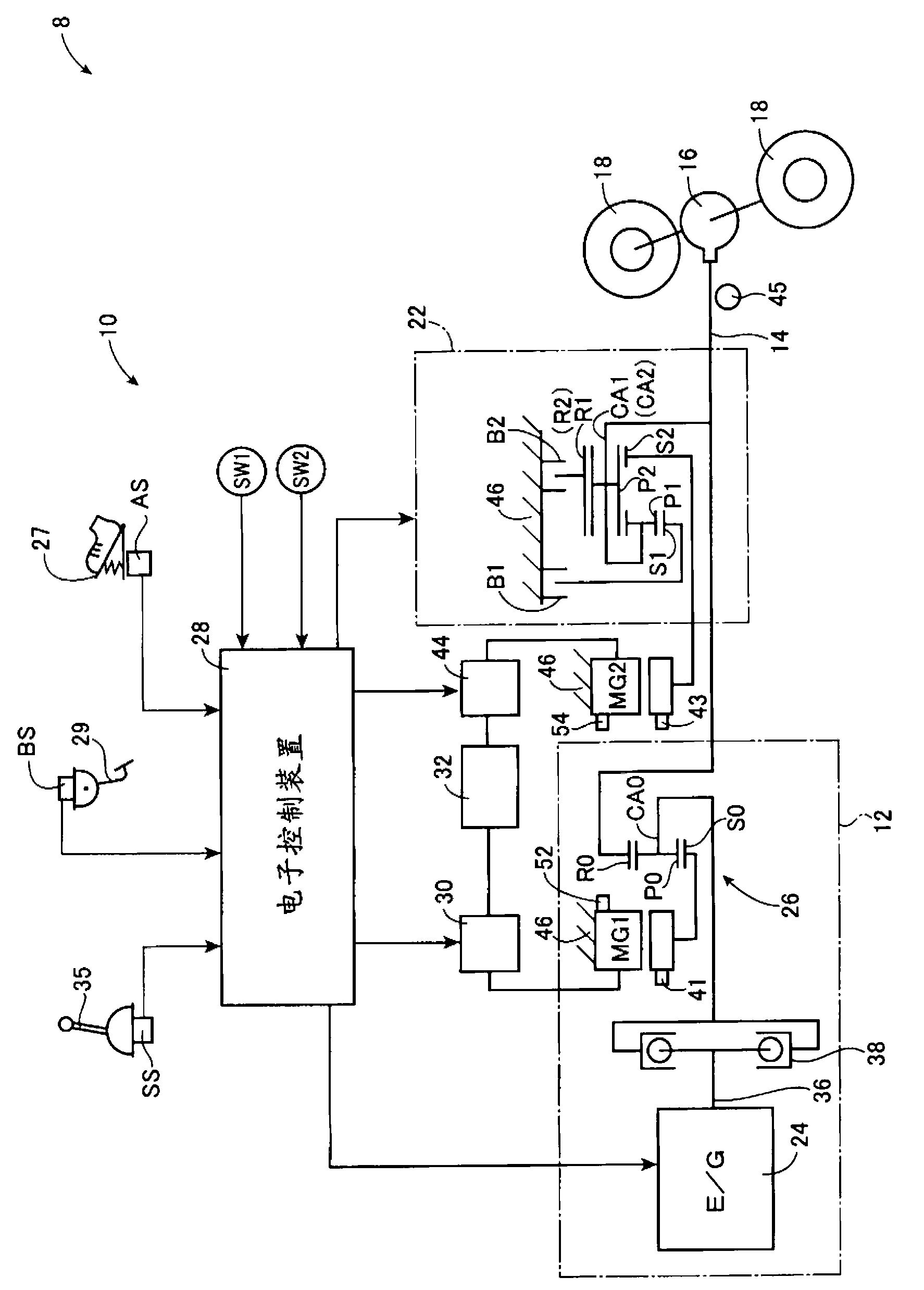

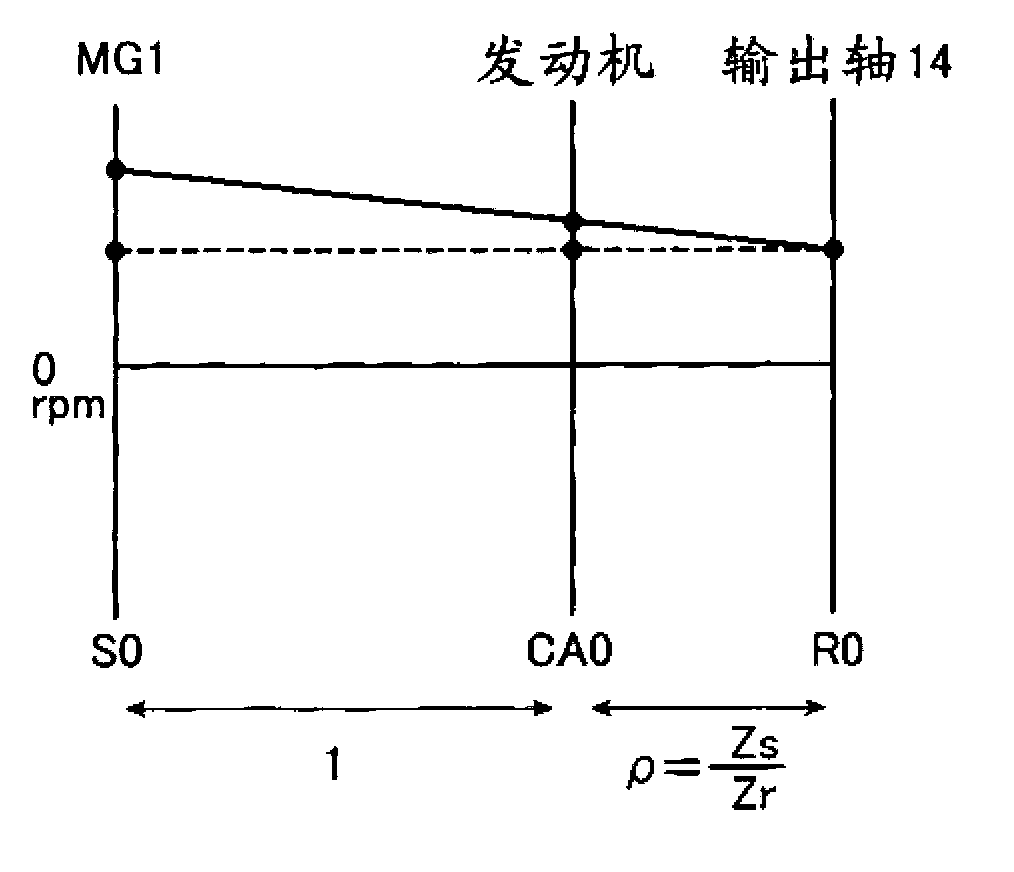

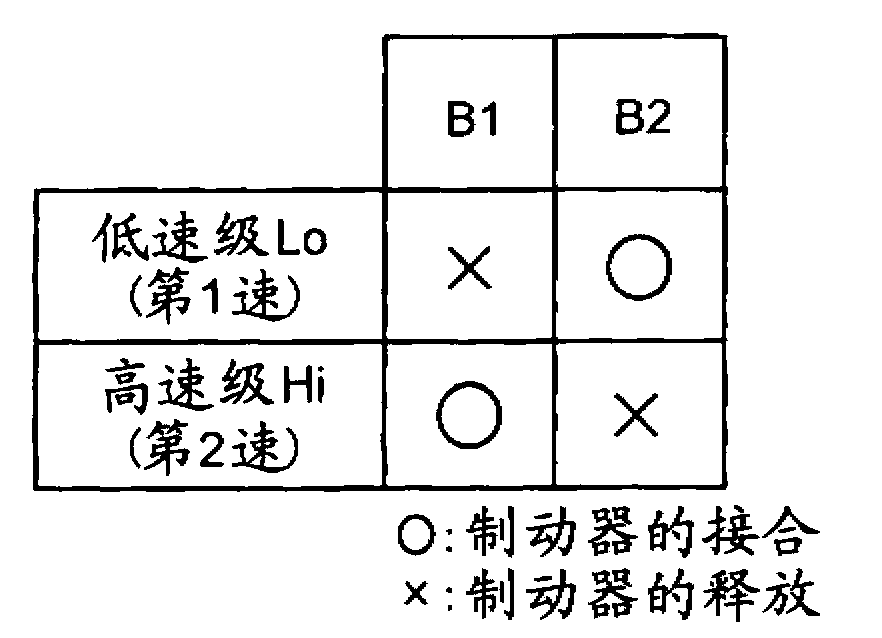

[0042] figure 1It is a schematic configuration diagram illustrating a vehicle drive device 10 used in a hybrid vehicle 8 (hereinafter referred to as "vehicle 8") to which the present invention is applied. figure 1 Among them, the vehicle drive device 10 includes: a first drive source 12 as a main drive source, a wheel-side output shaft 14 (hereinafter referred to as "output shaft 14") functioning as an output member, a differential gear device 16, a second 2 electric motor MG2, automatic transmission 22. In the vehicle drive device 10 , in the vehicle 8 , the torque of the first drive source 12 is transmitted to the output shaft 14 , and the torque is transmitted from the output shaft 14 to the pair of left and right drive wheels 18 via the differential gear unit 16 . . In addition, in this vehicle drive device 10 , the second electric motor MG2 capable of selectively performing power running control for outputting driving force for driving and regeneration control for recov...

Embodiment 2

[0104] In the present embodiment, an example will be described in which the motor torque suppression control is executed when the required drive force Freq once increases or decreases during parking and then increases again. For example, when the vehicle 8 is parked on a sandy road surface where it is difficult to start, the required drive force Freq may repeatedly increase and decrease. Therefore, the above-mentioned situation in which the required drive force Freq increases and decreases once and then increases again occurs. Hereinafter, differences from Embodiment 1 will be mainly described.

[0105] In this embodiment, the start mode switch 208 operated by the driver etc. (refer to Figure 10 ) are installed, for example, near a driver's seat where the driver can easily operate. When the stop start mode switch 208 is operated, the start mode selected when the vehicle 8 is started is selected. The above-mentioned start mode can be released manually, and it is preferable t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com