Copper foil for secondary battery negative electrode power collector

A technology for negative electrode current collectors and secondary batteries, applied in the direction of electrode carriers/current collectors, battery electrodes, circuits, etc., can solve problems such as increased roughness, existence limit, and increased roughness deviation, and achieve adhesion Excellent, the effect of reducing weight and thickness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

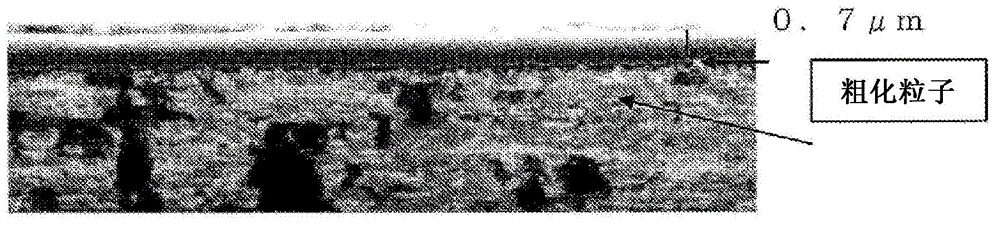

[0103] In Example 1, the average surface roughness Ra of the front and back sides measured by the laser microscope was 0.07 μm, and the three-dimensional surface area when the surface of the roughened surface was measured by the laser microscope was set as (A), and set as The two-dimensional area of the projected area during the measurement of the three-dimensional surface area is (B), set (A) / (B)=(C) when the calculated value is (C), and use a laser microscope to measure the unroughened rolled copper The three-dimensional surface area of the surface of the foil and copper alloy foil is (A'), and the two-dimensional area as the projected area when the three-dimensional surface area is measured is (B'), and (A') / (B')=( When the calculated value of C') is (C'), (C) / (C') is 1.004.

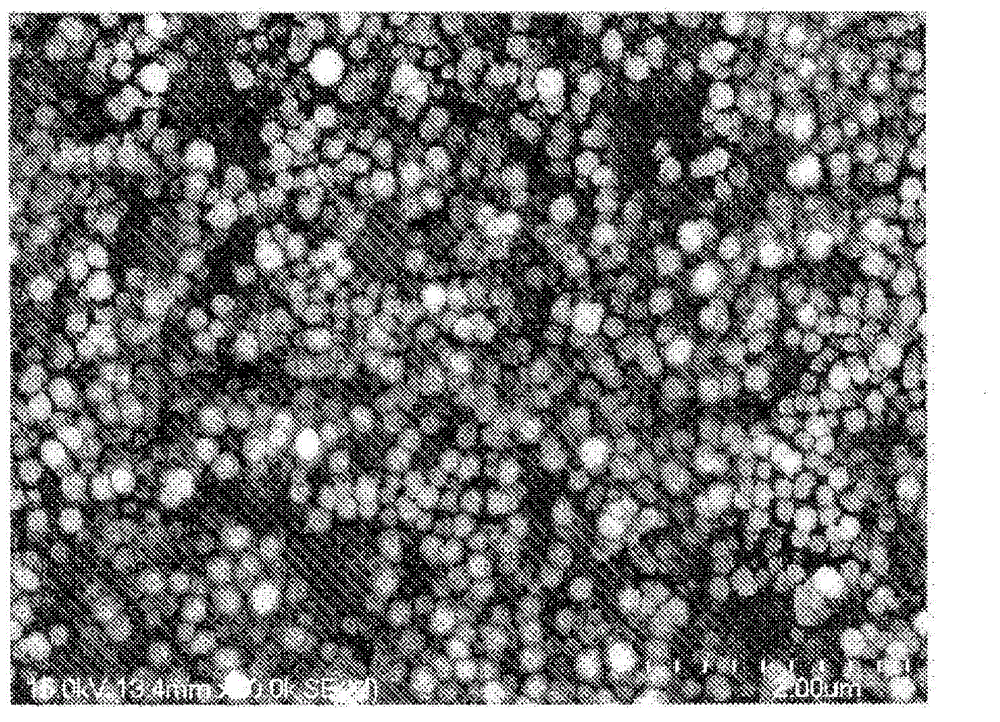

[0104] The SEM picture (20000 times) of the roughened particles at this time is like figure 1 Shown. As that figure 1 As shown, fine and uniform particles are formed. In addition, the average diame...

Embodiment 2)

[0111] In Example 2, the average surface roughness Ra of the front and back sides measured by the laser microscope was 0.07 μm, and the three-dimensional surface area when the roughened surface was measured by the laser microscope was set as (A). When the two-dimensional area of the projected area when measuring the surface area is (B), set (A) / (B)=(C) when the calculated value is (C), and use a laser microscope to measure the unroughened rolled copper foil and The three-dimensional surface area of the surface of the copper alloy foil is (A'), and the two-dimensional area that is the projected area when the three-dimensional surface area is measured is (B'), and (A') / (B')=(C') When the calculated value of) is (C'), (C) / (C') is 1.05.

[0112] In addition, the average diameter of the roughened particles on the roughened surface is 0.1~0.4μm, and the weight thickness deviation <0.5 (σ). In addition, the maximum height of the roughening treatment layer is 0.2 μm, which is within...

Embodiment 3)

[0114] In Example 3, the average surface roughness Ra of the front and back sides measured by the laser microscope was 0.15 μm, and the three-dimensional surface area of the roughened surface measured by the laser microscope was set as (A), and the three-dimensional When the two-dimensional area of the projected area when measuring the surface area is (B), set (A) / (B)=(C) when the calculated value is (C), and use a laser microscope to measure the unroughened rolled copper foil and The three-dimensional surface area of the surface of the copper alloy foil is (A'), and the two-dimensional area that is the projected area when the three-dimensional surface area is measured is (B'), and (A') / (B')=(C') When the calculated value of) is (C'), (C) / (C') is 1.03.

[0115] In addition, the average diameter of the roughened particles on the roughened surface is 0.1~0.4μm, and the weight thickness deviation <0.5 (σ). In addition, the maximum height of the roughening treatment layer is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com