The fuel cell

A fuel cell and electrolyte membrane technology, which is used in fuel cells, fuel cell components, and transportation fuel cell technology to achieve the effect of suppressing the reduction of power generation efficiency and preventing power generation from stopping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] (first embodiment)

[0040] refer to Figures 1 to 4 and 13 describe the fuel cell according to the first embodiment of the present invention.

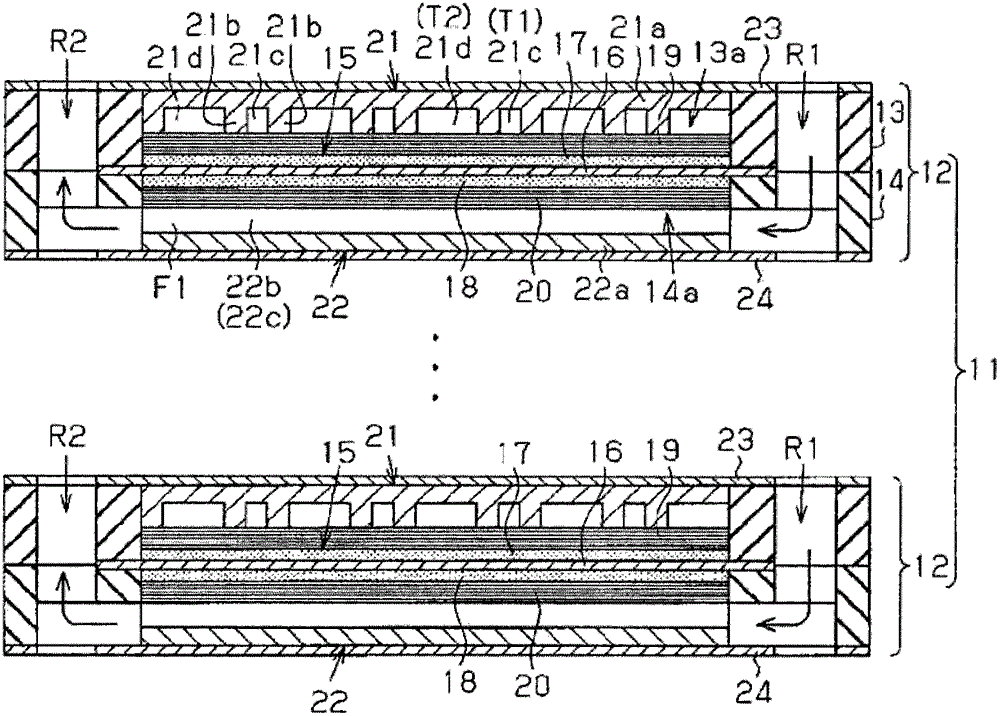

[0041] Such as Figure 13 As shown, the fuel cell stack 11 of the first embodiment is a solid polymer electrode electrolyte fuel cell, and includes a plurality of stacked power generation cells 12 .

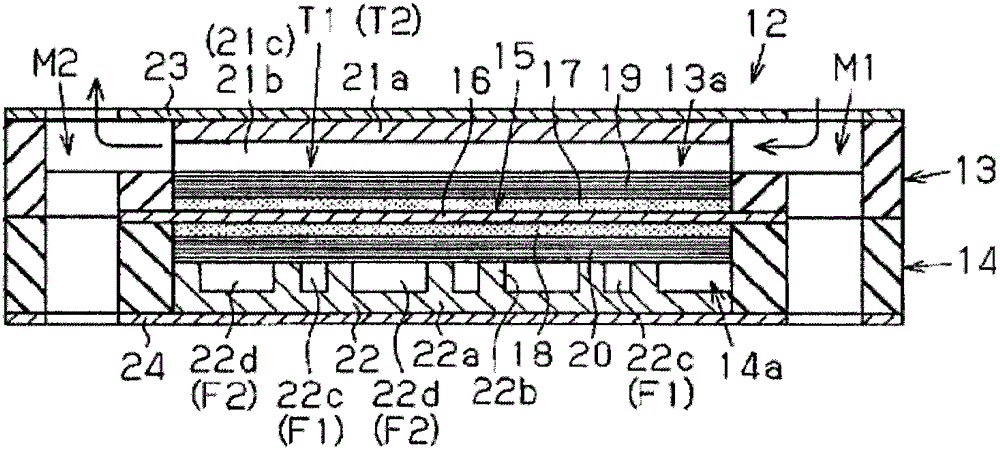

[0042] Such as figure 1 As shown, these power generation cells 12 each include square first and second frames 13 , 14 , and a membrane electrode assembly (MEA) 15 as an electrode structure positioned within the first and second frames 13 , 14 . The first and second frames 13, 14 are made of synthetic resin such as synthetic rubber. A passage space 13 a for fuel gas is formed in the first frame 13 , and a passage space 14 a for oxidizing gas is formed in the second frame 14 . The membrane electrode assembly 15 is positioned between the first and second frames 13 , 14 .

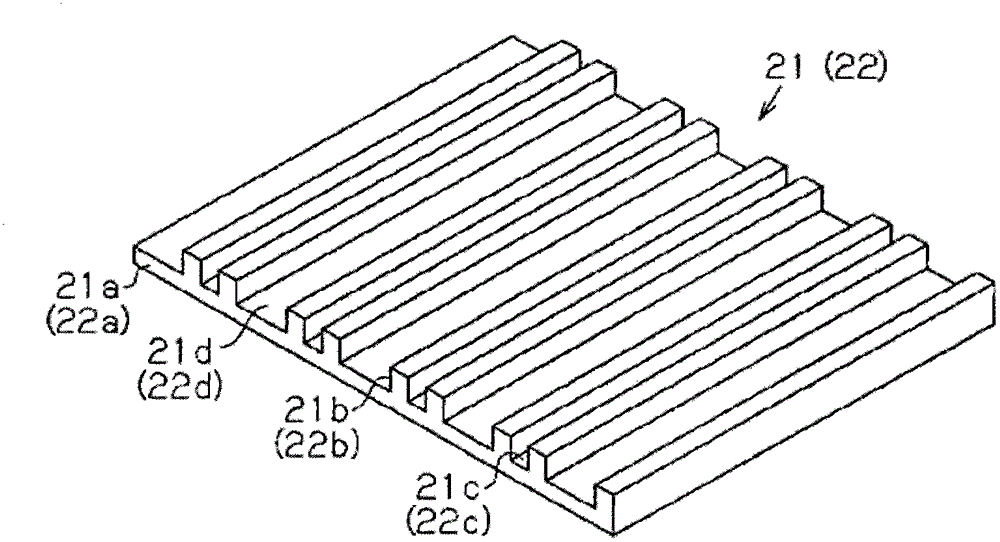

[0043] Such as figure 1 and 2 As shown, each power g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com