Folded pearl cotton package and manufacturing method thereof

A technology for packaging parts and pearl cotton, which is applied in packaging, transportation and packaging, container manufacturing machinery, etc., can solve the problems of irregular shape and structure of finished parts, inability to change the length of connecting parts, and low utilization rate of stacking space, and saves money. The effect of raw materials, shortening production cycle, and saving warehousing and logistics space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

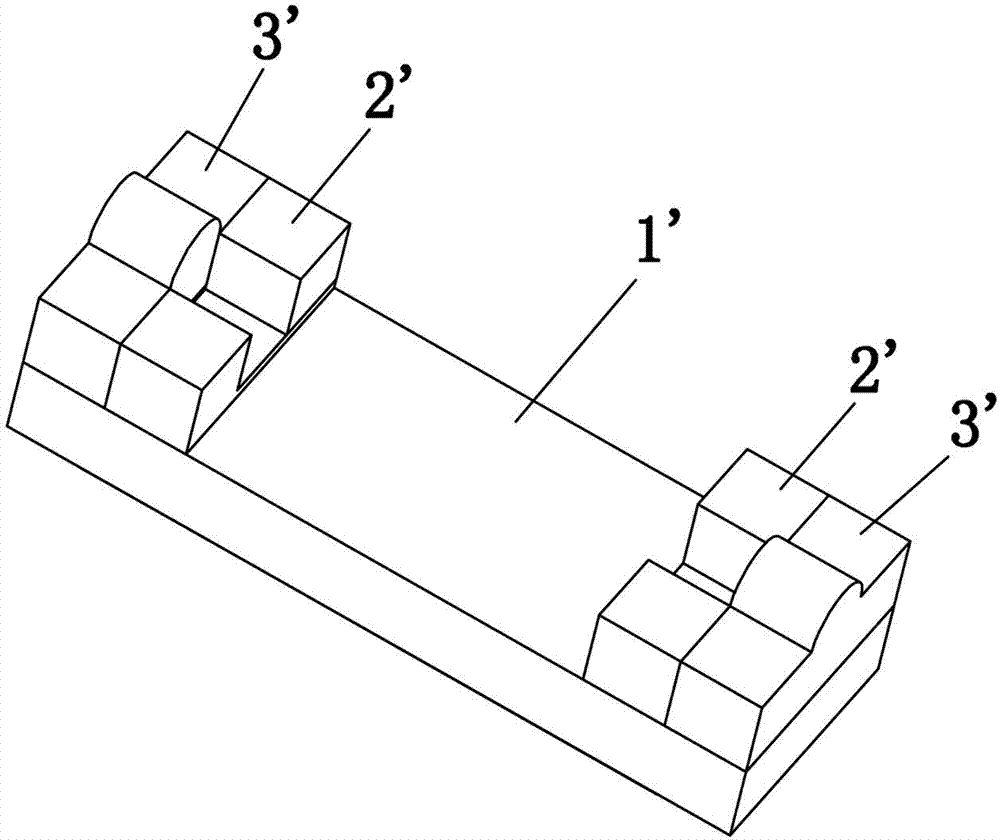

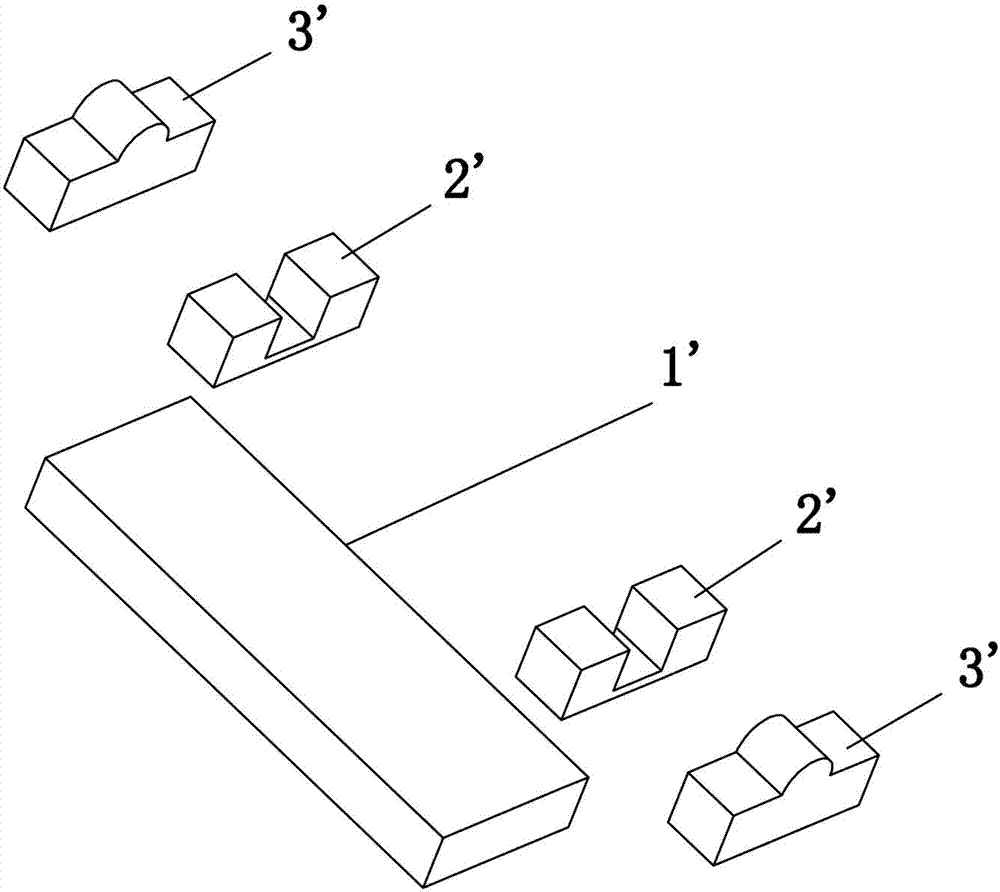

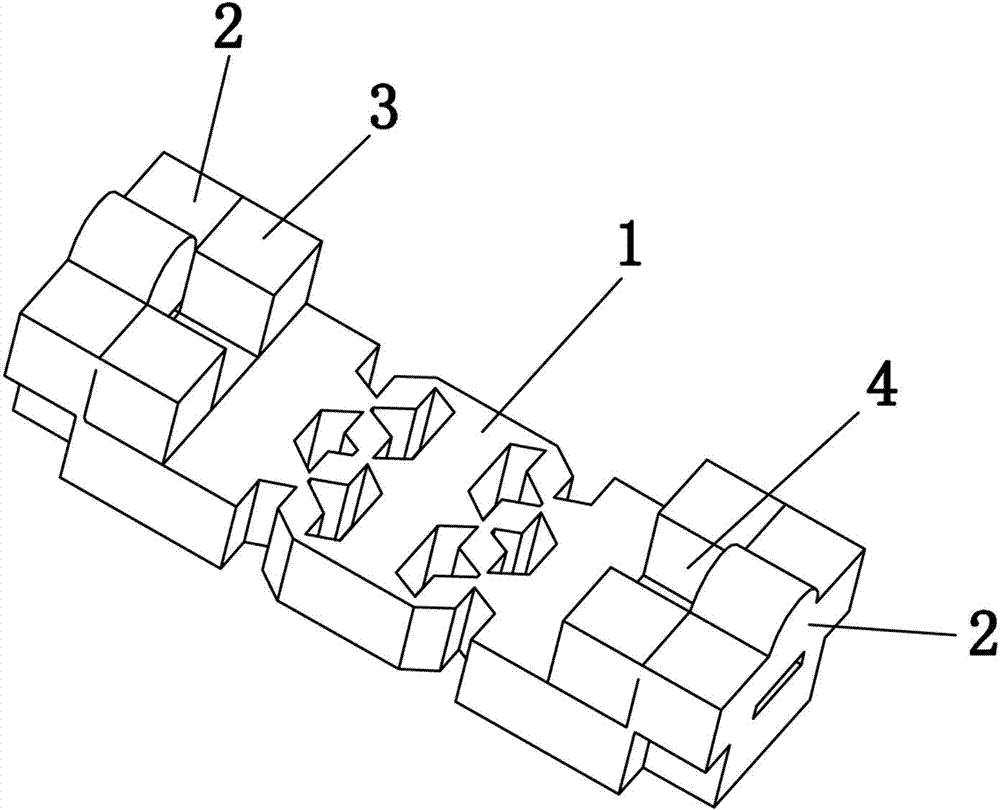

[0033] A method for manufacturing a folded pearl cotton package, the method comprising: adopting a die-cutting method to cut the components of the package on a whole pearl cotton board at one time, and the pearl cotton board is composed of multiple layers of pearl cotton sheets It is compounded, one side of the surface layer is a high-density pearl cotton sheet with a foaming ratio of 10-25 times, and the other pearl cotton sheets are commonly used in density, and its foaming ratio is generally 30-40 times. The high-density pearl cotton sheet has Strong toughness can ensure that it will not be broken during the folding process.

[0034] There are three kinds of die-cutting incisions. The first one is a non-through linear folding incision. The bottom of the folding incision extends to the surface of the high-density pearl cotton sheet. The second one is a through middle incision. After the part in the middle incision is removed Form the self-locking receiving interface and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com