Processing method of organic water discharge by membrane separation activated sludge device

A treatment method and activated sludge technology, applied in water/sludge/sewage treatment, biological water/sewage treatment, osmosis/dialysis water/sewage treatment, etc., can solve the problem of unstable filtration treatment and insufficient decomposition ability of BOD components And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

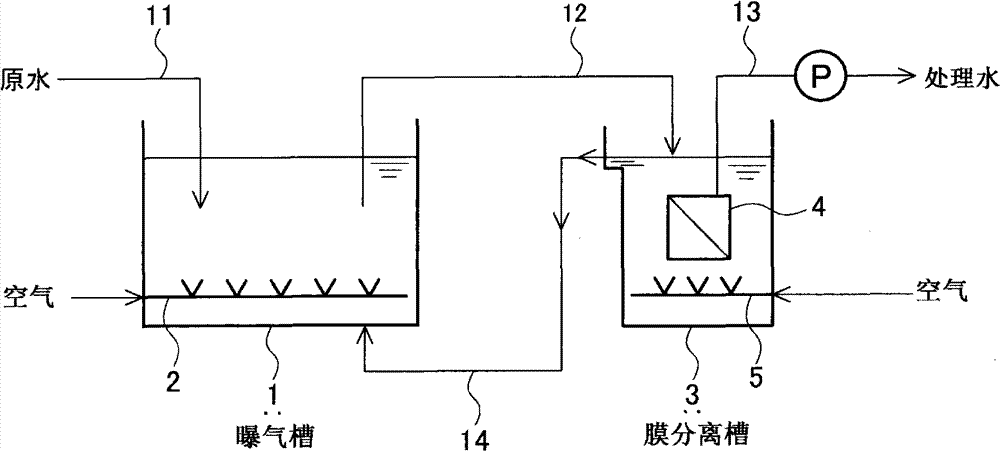

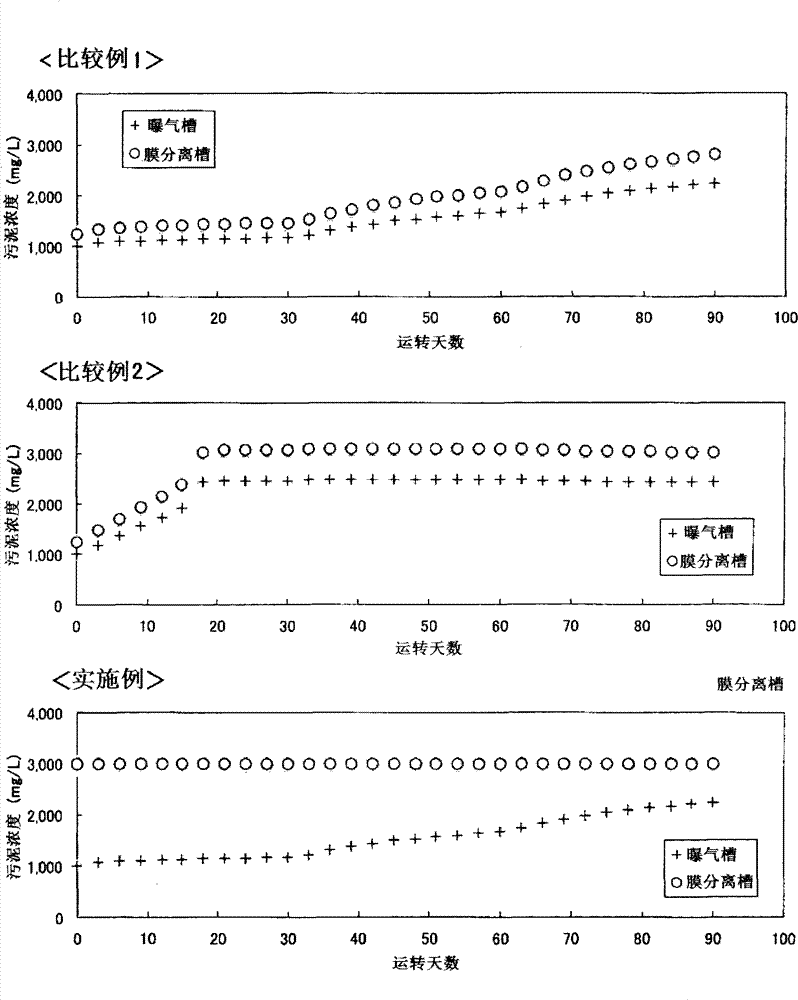

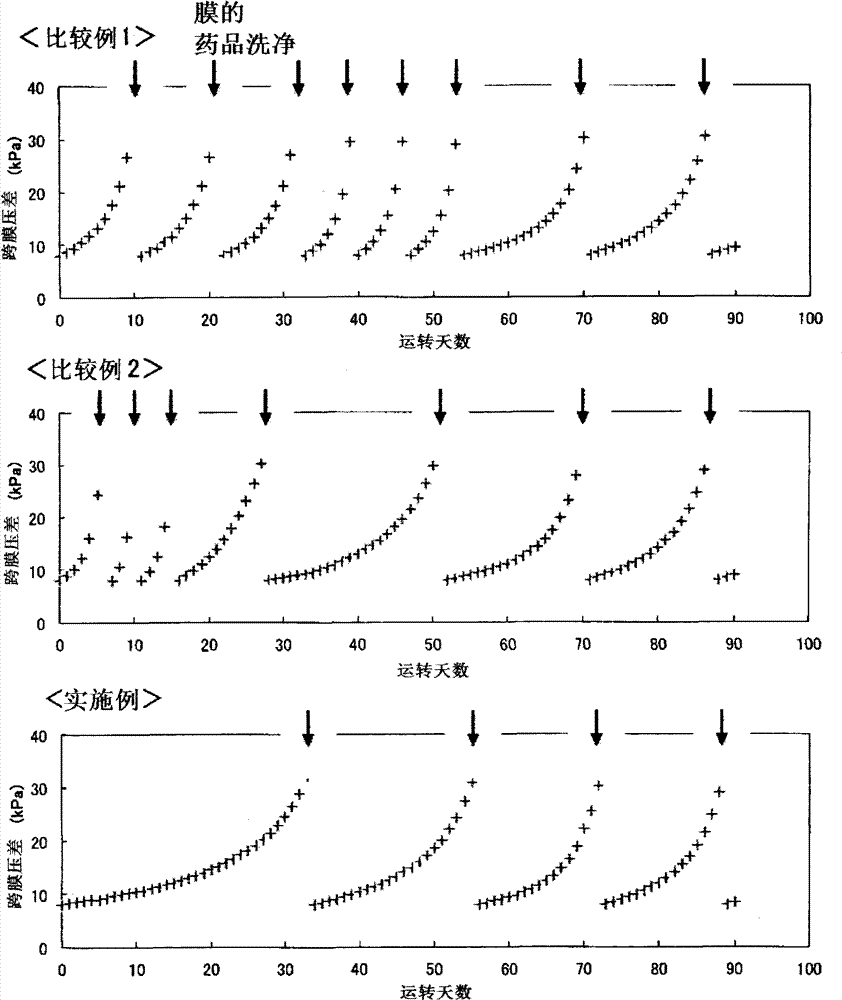

[0036] Next, examples and comparative examples will be described. The raw water used in the following examples and comparative examples is as follows, and the following aeration tank and membrane separation tank are adopted. figure 1 The device shown is processed.

[0037] [raw water]

[0038] Simulated drainage of liquid crystal manufacturing plants (raw water supplied for the first 30 days, including MEA80mg / L, DMSO40mg / L, and nutrient inorganic salts. BOD concentration 100mg / L.)

[0039] Raw water supply 4m 3 / d

[0040] [Aeration tank and membrane separation tank]

[0041] Aeration tank 2m 3 . It is configured to supply sludge to the membrane separation tank at a predetermined flow rate, and return the sludge overflowing from the membrane separation tank to the aeration tank.

[0042] Membrane separation tank 0.4m 3 . Impregnation of Mitsubishi Rayon (Mitsubishi Rayon) MF membrane (membrane area 6m 2 ), according to the cycle of 7 minutes of filtration / 1 minute o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com