Cross-linking agent for fracturing fluid with ultralow hydroxypropyl guar concentration and fracturing fluid prepared from cross-linking agent

A technology of ultra-low hydroxypropyl melon and fracturing fluid, applied in drilling compositions, chemical instruments and methods, etc., can solve the problem of high residue content, achieve low residue content, good sand-carrying performance, and reduced dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a cross-linking agent for fracturing fluid with an ultra-low hydroxypropyl guar concentration and a fracturing fluid prepared therefrom.

[0046] The cross-linking agent provided in this embodiment includes the following components in parts by mass:

[0047] 450 parts of water;

[0048] 150 parts of sodium gluconate;

[0049] 100 parts of borax;

[0050] 70 parts of sorbitol;

[0051] 10-50 parts of sodium hydroxide.

[0052] The cross-linking agent provided in this embodiment is prepared according to the following steps:

[0053] Stir and mix the sodium gluconate and water evenly, slowly add borax under stirring conditions, and then react at 70°C-80°C for 2 hours to obtain a mixture;

[0054]Adding sodium hydroxide to the mixture to adjust the pH value to 6-8, stirring and reacting at 70°C-80°C for 3 hours;

[0055] Then add sorbitol, stir and react at 70°C-80°C for 1 hour to prepare the crosslinking agent.

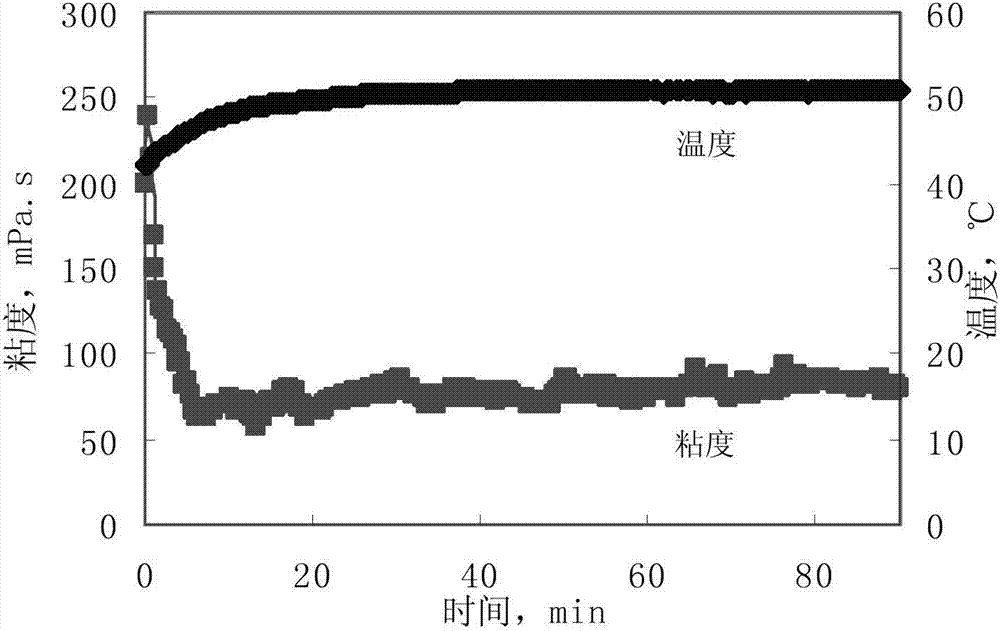

[0056] The present embodimen...

Embodiment 2

[0072] This embodiment provides a cross-linking agent for fracturing fluid with an ultra-low hydroxypropyl guar concentration and a fracturing fluid prepared therefrom.

[0073] The cross-linking agent provided in this embodiment includes the following components in parts by mass:

[0074] 450 parts of water;

[0075] Sodium gluconate 180 parts;

[0076] 150 parts of borax compound;

[0077] 70 parts of sorbitol;

[0078] 10-50 parts of sodium hydroxide.

[0079] The cross-linking agent provided in this embodiment is prepared according to the following steps:

[0080] Stir and mix the sodium gluconate and water evenly, slowly add borax under stirring conditions, and then react at 70°C-80°C for 2 hours to obtain a mixture;

[0081] Adding sodium hydroxide to the mixture to adjust the pH value to 6-8, stirring and reacting at 70°C-80°C for 3 hours;

[0082] Then add sorbitol, stir and react at 70°C-80°C for 1 hour to prepare the crosslinking agent.

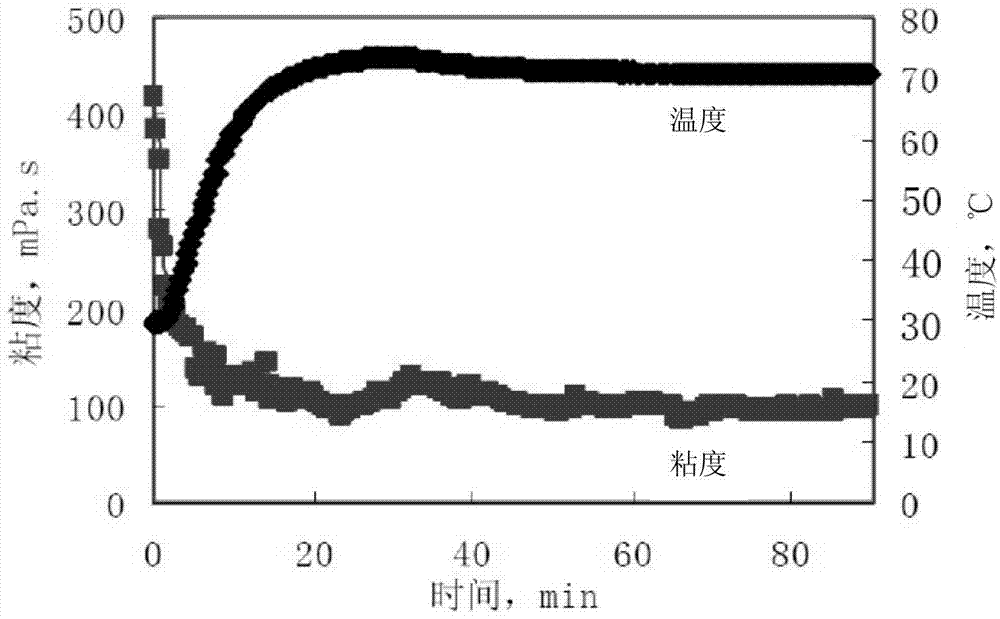

[0083] The present em...

Embodiment 3

[0099] This embodiment provides a cross-linking agent for fracturing fluid with an ultra-low hydroxypropyl guar concentration and a fracturing fluid prepared therefrom.

[0100] The cross-linking agent provided in this embodiment includes the following components in parts by mass:

[0101] 450 parts of water;

[0102] Sodium gluconate 230 parts;

[0103] 250 parts of borax compound;

[0104] Xylitol 130 parts;

[0105] 10-50 parts of sodium hydroxide.

[0106] The cross-linking agent provided in this embodiment is prepared according to the following steps:

[0107] Stir and mix the sodium gluconate and water evenly, slowly add borax under stirring conditions, and then react at 70°C-80°C for 2 hours to obtain a mixture;

[0108] Adding NaOH to the mixture to adjust the pH value to 6-8, stirring and reacting at 70°C-80°C for 3 hours;

[0109] Then add xylitol, and stir and react at 70°C-80°C for 1 hour to prepare the crosslinking agent.

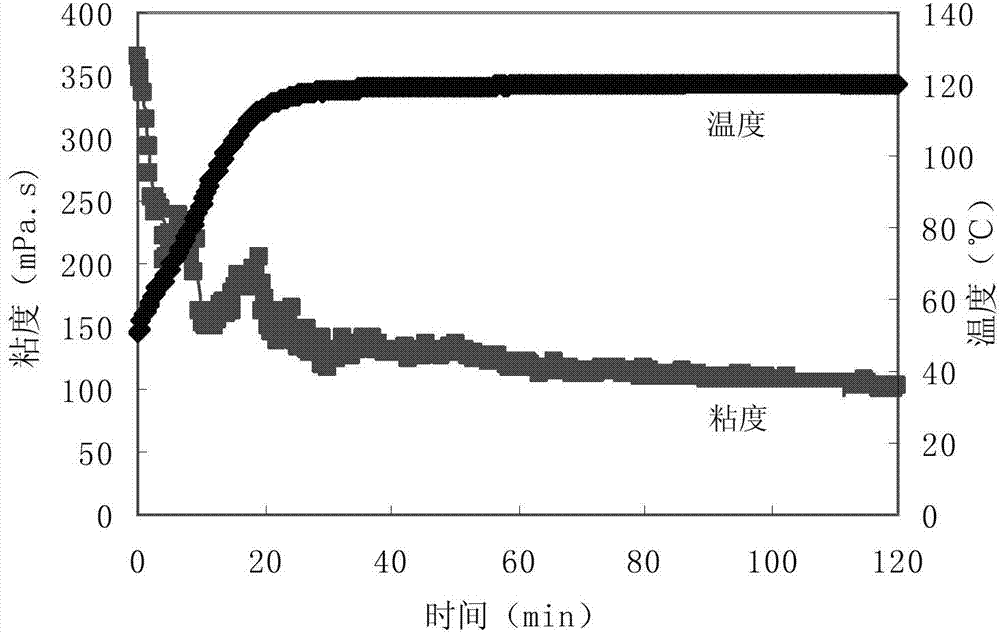

[0110] The present embodiment pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com