High-performance ocean platform steel and its production method

An offshore platform, high-performance technology, applied in the field of steel plate manufacturing, can solve the problems of low low temperature toughness, affecting the use of steel plates, etc., to achieve the effect of high low temperature impact energy, good structure, and ensure hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

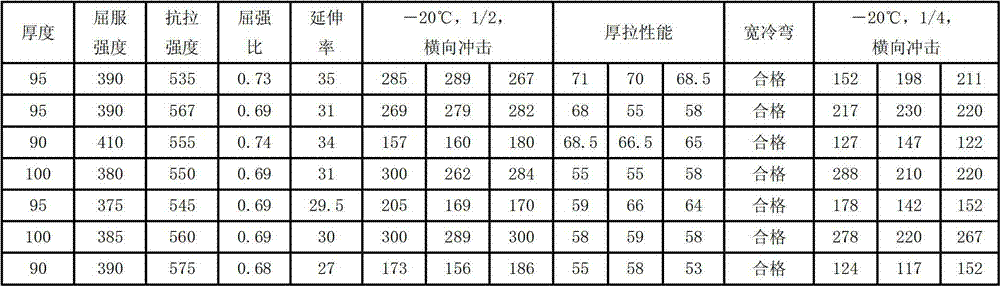

Embodiment 1

[0036] The thickness of the steel for offshore platforms in this embodiment is greater than 90 mm, and the actual composition (by weight percentage) of the steel plate is: C: 0.10%, Si: 0.28%, Mn: 1.56%, P: 0.010%, S: 0.001%, Al : 0.037%, Nb: 0.037%, V: 0.075%, Ti: 0.045%, the balance is Fe and unavoidable impurities, Ceq is 0.40%, and Pcm is 0.20%.

[0037] The production method of steel plate of the present invention is as follows:

[0038](1) Smelting: The molten steel is first smelted in an electric furnace. When tapping the ladle, add 1 ton of the alloy, including the deoxidizer Si-Mn, to avoid the increase in the degree of overoxidation of the molten steel, and when tapping the ladle, P must be less than 0.008%, it is not allowed to see slag to produce steel; send it to LF refining furnace for refining, and feed 650 meters of Al wire, 1720kg of lime, 123kg of Si-Fe powder, keep white slag for 55min, vacuum treatment in VD furnace, add SiCa block 130kg / Furnace, the vacu...

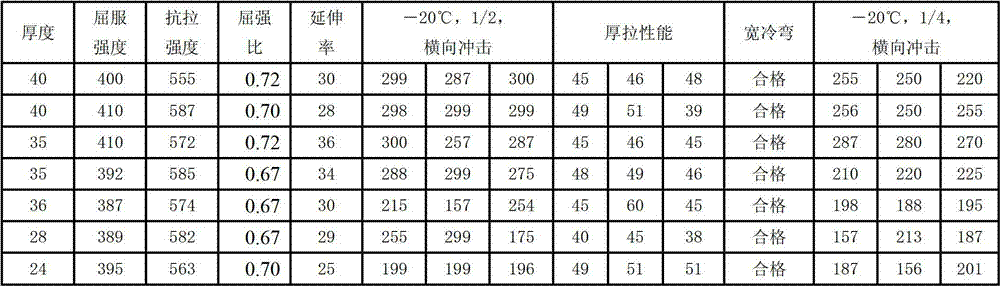

Embodiment 2

[0048] The thickness of the steel for the offshore platform in this embodiment is ≤40mm, and the actual composition (by weight percentage) of the steel plate is: C: 0.12%, Si: 0.27%, Mn: 1.48%, P: 0.009%, S: 0.001%, Al: 0.038%, Nb: 0.027%, V: 0.038%, the balance is Fe and unavoidable impurities, Ceq is 0.38%, and Pcm is 0.21%.

[0049] The production method of steel plate of the present invention is as follows:

[0050] (1) Smelting: The molten steel is first smelted in an electric furnace. When tapping the ladle, add 1 ton of the alloy, including the deoxidizer Si-Mn, to avoid the increase in the degree of overoxidation of the molten steel, and when tapping the ladle, P must be less than 0.008%, it is not allowed to see slag to produce steel; send it to LF refining furnace for refining, and feed 650 meters of Al wire, 1720kg of lime, 123kg of Si-Fe powder, keep white slag for 55min, vacuum treatment in VD furnace, add SiCa block 130kg / Furnace, the vacuum degree is 66Pa, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com