Fully-recycled body expanding anchor rod and construction method for anchoring ground using same

A technology of body expansion and anchor bolts, which is applied in excavation, foundation structure engineering, sheet pile walls, etc., can solve the problems of unfavorable saving of steel, cement, energy saving and emission reduction, waste of anchor reinforcement materials, and rising cost of hole formation, etc., to achieve effective It is beneficial to energy saving and emission reduction, reducing the number of punching holes and saving transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

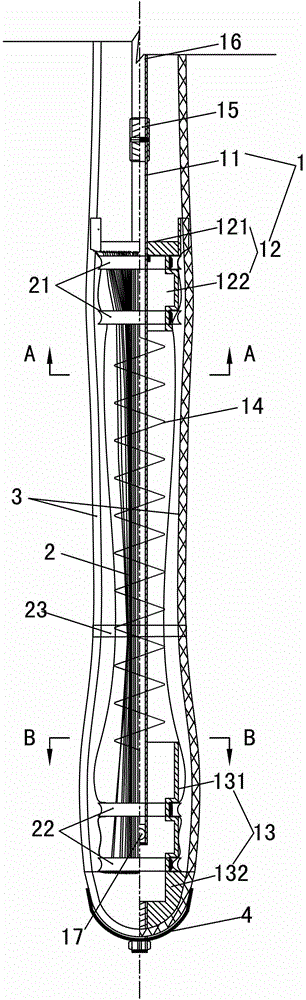

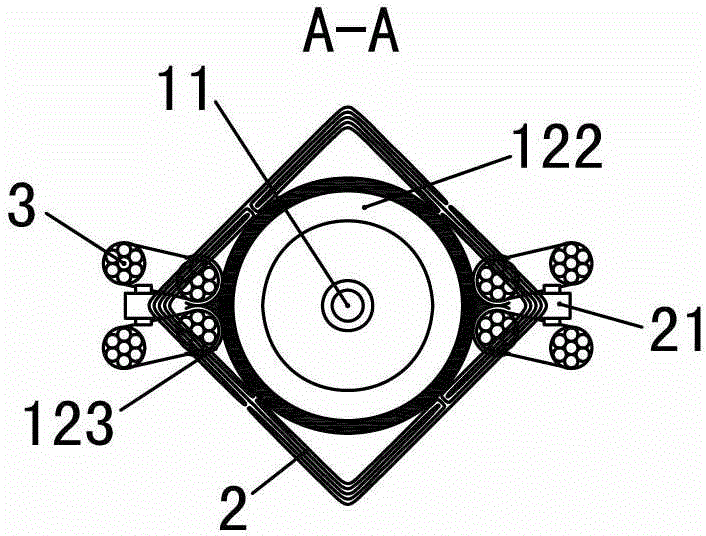

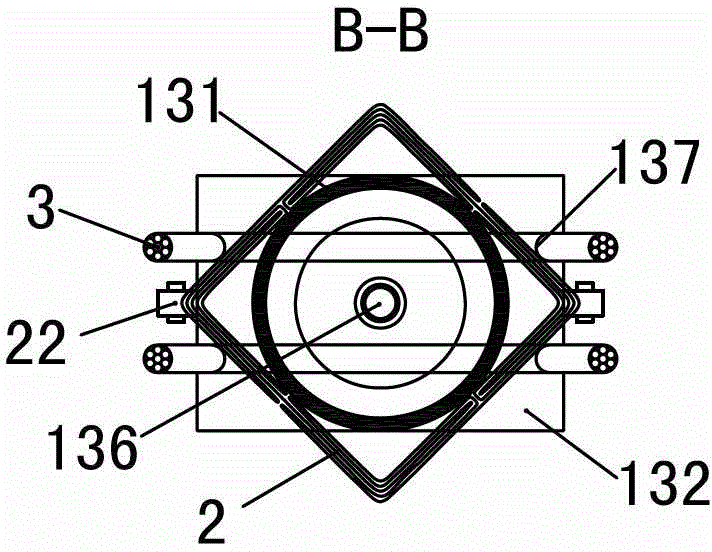

[0039] Such as figure 1 As shown, the fully recyclable expansion anchor of the present invention includes a main frame 1, a sealed covering bag 2, an unbonded steel strand 3, and a guide cover 4, such as Figure 4 As shown, the main frame 1 includes a grouting core pipe 11, an upper assembly 12 arranged on the upper part of the grouting core pipe 11, a lower assembly 13 arranged on the lower part of the grouting core pipe 11, wound on the grouting core pipe 11 and upper, The lower two ends are respectively fixed on the spiral stirrups 14 on the upper and lower assemblies 12, 13, such as Figure 5 , 6 As shown, the upper assembly 12 includes an integrally formed upper cover plate 121 and an upper sleeve 122, the upper sleeve 122 is arranged below the upper cover plate 121, the bottom surface of the upper cover plate 121 is provided with a central hole 120, and the central hole is provided with threads. Two fixed jaws 123 are respectively provided on both sides of the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com