Staged fracturing construction yield increment method for waterpower in deep thickened oil deposit thick-bedded sandstone storage layer

A heavy oil reservoir and staged fracturing technology, which is applied in the directions of earth-moving drilling, fluid production, wellbore/well components, etc. , the problems such as lamination fracturing can not be realized, to achieve the effect of increasing the filling gap width and longitudinal filling degree, fast operation and large stress difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

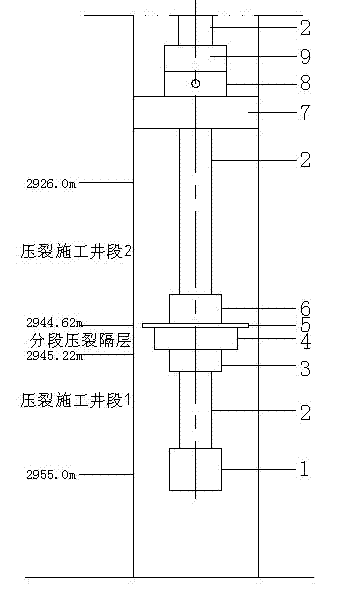

[0048] Example 1: Fracturing construction mode of perforated and unfractured layers in old wells

[0049] The production stimulation method of the present invention is applied to Yudong 204-114 well, and the production well section is 2926-2955.0 meters.

[0050] The construction steps are as follows:

[0051] 1. Identify oil-free calcareous interlayers, muddy interlayers, and physical interlayers in the production well section of 2926-2955.0 meters, and select interlayers.

[0052] According to the readings of well logging curves, compared with different interlayer electrical logging identification standards and rock mechanics parameter tables (or according to the readings on the electrical logging identification chart), the perforated section of 2926-2955.0 meters in the oil layer (2926.0-2933.47m, 2934.07-3944.62m, 2945.22-2955.0m), preferably 2944.62-2945.22m calcareous interlayer is staged fracturing barrier.

[0053] (1) The electrical measurement identification standa...

Embodiment 2

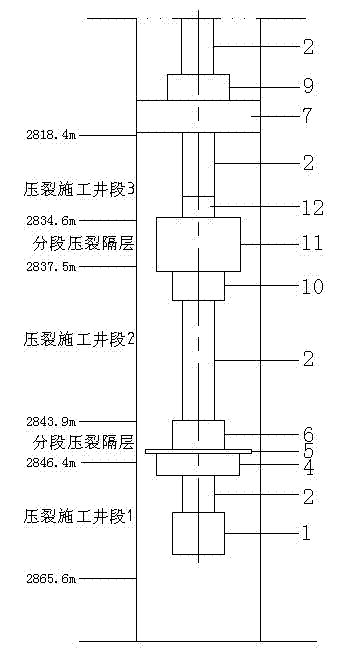

[0082] Example 2: Construction mode of perforated and fractured layers in old wells

[0083] The production stimulation method of the present invention is applied to well Yudong 204-5, and the production interval is 2818.4-2886.4 meters.

[0084] The construction steps are as follows:

[0085] 1. Using the interlayer identification method described in Example 1, the 2834.6-2837.5 m mud interlayer and the 2843.9-2846.4 m calcareous interlayer are preferably used as staged fracturing interlayers in the production perforated section; In the main water-producing well section, water blocking proppant was used to seal the old fractures for water blocking; the 2837.5-2843.9m well section adopted the technology of balancing the middle layer to protect the middle layer, and no fracturing was carried out; the 2818.4-2834.6m well section implemented stimulation fracturing.

[0086] 2. Install cable blowout preventer, cable transmission large-aperture coverage perforation, 2821.00-2822.7...

Embodiment 3

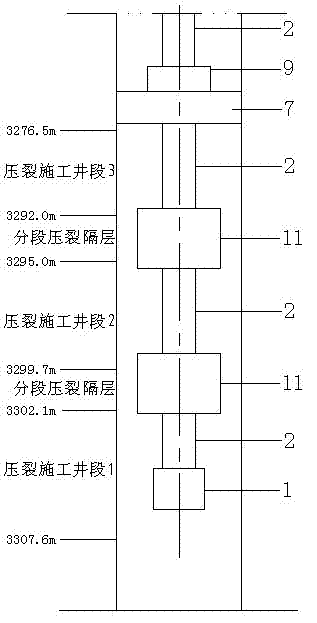

[0102] Example 3: Non-water-controlled fracturing construction mode for new wells and new perforated layers

[0103] The production stimulation method of the present invention is applied to Yudong 17-17 well, and the new well is put into production in the 3276.5m-3299.7m and 3302m-3307.6m well sections of the T2K2 oil layer group.

[0104] The construction steps are as follows:

[0105] 1. Using the interlayer identification and evaluation method described in Example 1, the 3302.1-3299.7 m calcareous interlayer and the 3295-3292 m lithological interlayer are preferably used as fracturing interlayers in the production well section.

[0106] 2. Install cable BOP, magnetic positioning depth correction, cable transmission large-aperture perforation, gun type Huabei 102-16, Daqing 54 bullet type, hole density 16 holes / m, hole diameter 33.5mm, penetration depth 255mm, total hole 343 holes were counted, 343 holes were actually shot, and the perforation rate was 100%.

[0107] 3. L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com