Inflation tool device of absorber

A shock absorber and tooling technology, which is applied in the container filling method, the container discharge method, and the equipment loaded into the pressure vessel, etc., can solve the problems of slow push rod speed, low work efficiency and low reliability of hydraulic equipment. , to achieve the effect of good sealing, convenient operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

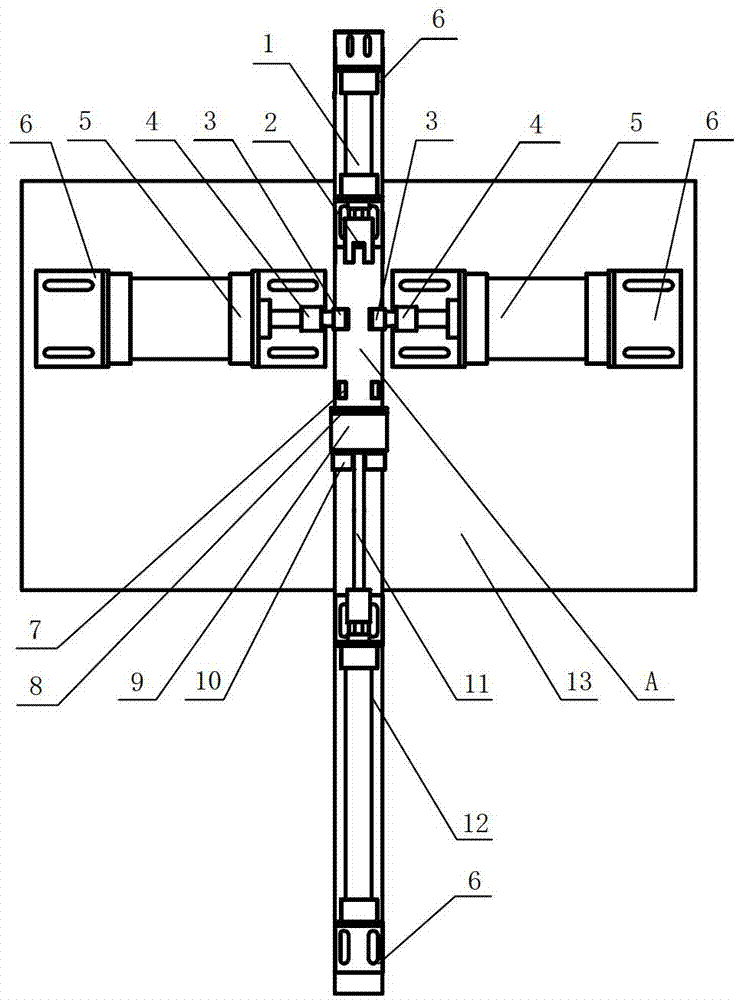

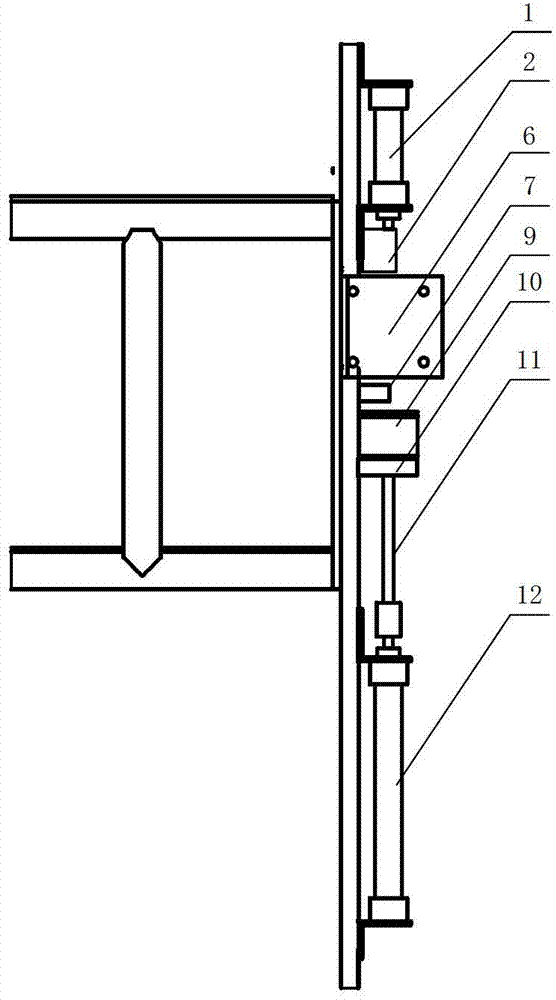

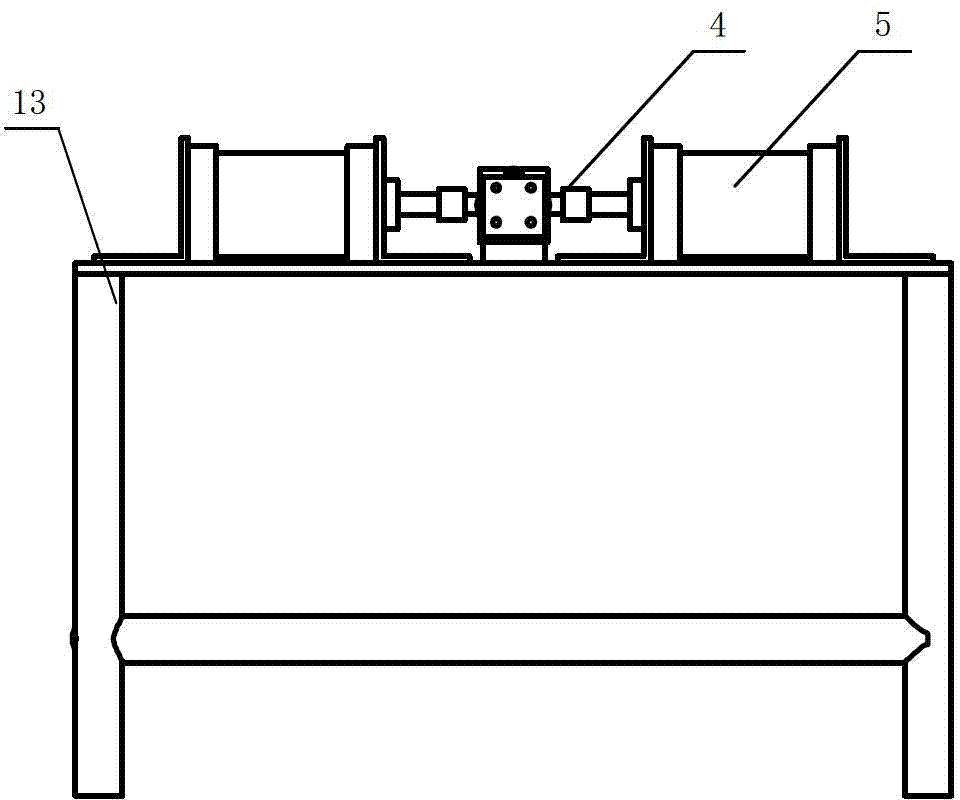

[0030] A shock absorber inflation tooling device, including an electrical control system, a positioning mechanism installed on a tooling platform 13, an inflation mechanism and a pressure point mechanism, the positioning mechanism is used to fix the shock absorber cylinder 14, including a positioning cylinder 1, The pressing base block 2, the cylinder positioning block 3 and the cylinder positioning V-shaped block 7, the pressing base block 2, the cylinder positioning block 3 and the cylinder positioning V-shaped block 7 are respectively located at the front of the pneumatic cylinder station, In the middle and the tail, the positioning cylinder 1 is installed on the front end of the pressing base block 2 through the cylinder fixing block 6 and is on the same central axis as the pneumatic cylinder tube station, and the piston end of the positioning cylinder 1 is connected with the pressing base block 2.

[0031] The inflation mechanism is used to press the floating piston into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com