Energy-saving method for sizing and drying soft capsules

A drying method and soft capsule technology, applied in the directions of capsule transportation, drying gas arrangement, drying, etc., can solve the problems of long time, large energy consumption, and large floor space, and achieve small working temperature difference, high efficiency, and improved efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

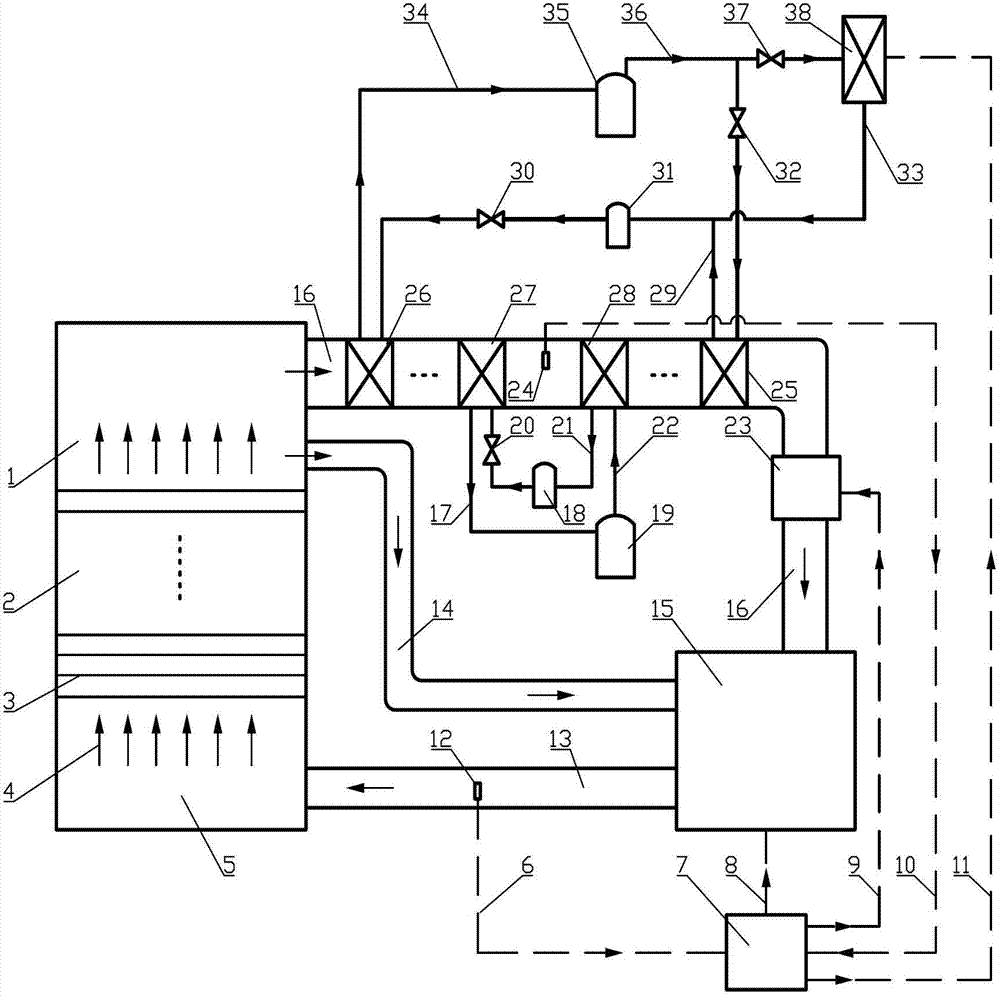

[0024] The principle of the workflow structure of an energy-saving soft capsule shaping and drying method involved in this embodiment is as follows: figure 1 Shown; by internal circulation heat pump unit evaporator 27, internal circulation heat pump unit suction pipe 17, internal circulation heat pump unit compressor 19, internal circulation heat pump unit exhaust pipe 22, internal circulation heat pump unit condenser 28, internal circulation heat pump unit Liquid return pipe 21, internal circulation heat pump unit liquid storage tank 18, internal circulation heat pump unit throttle valve 20, external circulation heat pump unit evaporator 26, external circulation heat pump unit suction pipe 34, external circulation heat pump unit compressor 35, external circulation Heat pump unit exhaust pipe 36, outer circulation heat pump unit external heat discharge regulating valve 37, outer circulation heat pump unit condenser 38, outer circulation heat pump unit inner heat supply regulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com