Flexible thermal diode and preparation method and application thereof

A thermal diode and flexible technology, applied in the field of flexible thermal diode, its preparation, can solve the problems of restricting wide application and inability to obtain flexibility, etc., and achieve the effect of wide application prospect, easy large-scale production, and small working temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

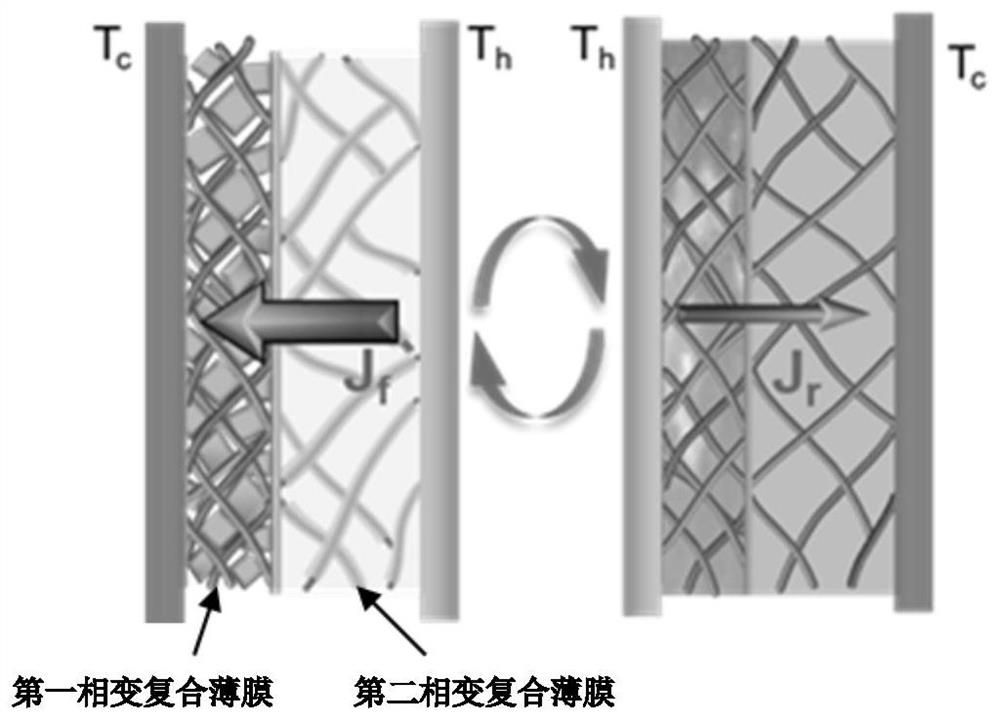

[0050] Another aspect of the embodiments of the present invention also provides the aforementioned method for preparing a flexible thermal diode, which includes:

[0051] The negative temperature coefficient phase change material and the positive temperature coefficient phase change material are respectively loaded into the holes of the aerogel film, so as to obtain the first phase change composite film and the second phase change composite film respectively;

[0052] And, the first phase change composite film and the second phase change composite film are assembled to form the flexible thermal diode.

[0053] Further, the aerogel film is a high-strength, flexible self-supporting aerogel film.

[0054] In some specific embodiments, the preparation method specifically includes: using capillary action to load the negative temperature coefficient phase change material in a molten state or a solution state into the inside of the aerogel film to prepare a first phase change composi...

Embodiment 1

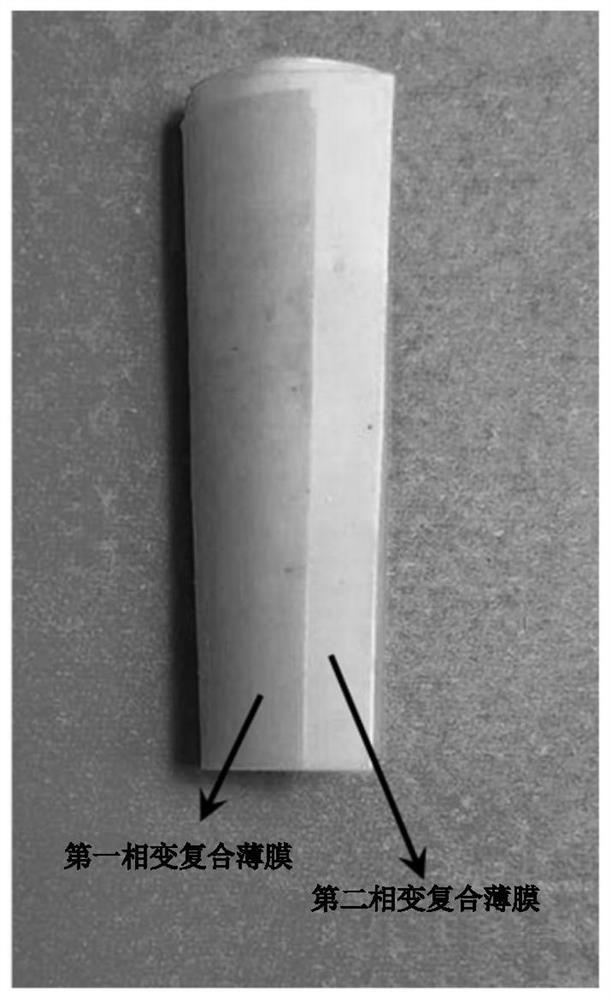

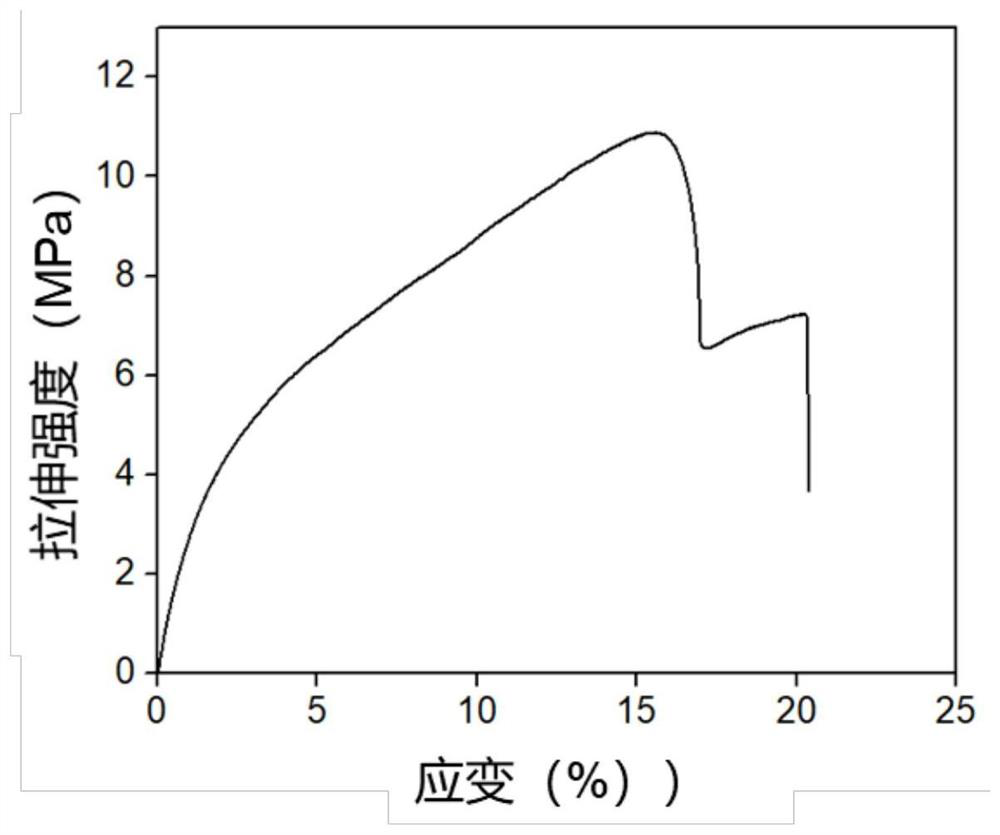

[0068] Paraffin (paraffin) and PNIPAM aqueous solution were selected as negative temperature coefficient phase change materials and positive temperature coefficient phase change materials with opposite thermal conductivity temperature coefficients, respectively, and then loaded into Kevlar aerogel films of different thicknesses, respectively, to obtain paraffin / Kevlar The phase-change composite film and the PNIPAM / Kevlar phase-change composite film, with a thickness ratio of 1:10, were cut into the same size, attached together, and assembled into a flexible thermal diode. figure 2 A schematic structural diagram of the flexible thermal diode obtained in this embodiment is shown, and other parameters are shown in Table 1.

Embodiment 2

[0070] Paraffin (paraffin) and PNIPAM aqueous solution were selected as negative temperature coefficient phase change materials and positive temperature coefficient phase change materials with opposite thermal conductivity temperature coefficients, respectively, and then loaded into the densified Kevlar aerogel films, respectively, to obtain paraffin / D-Kevlar phase change composite film and PNIPAM / D-Kevlar phase change composite film, the thickness ratio of the two is 1:5, they are cut into the same size, and they are laminated together to assemble a flexible thermal diode. Please refer to Table 1 for detailed parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com