Technology for producing AAQFN framework product quad flat package on basis of sand blasting

A manufacturing process and flat packaging technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems affecting product service and life, achieve low cost, reduce the probability of delamination, and improve The effect of product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

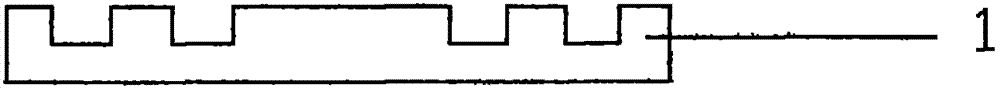

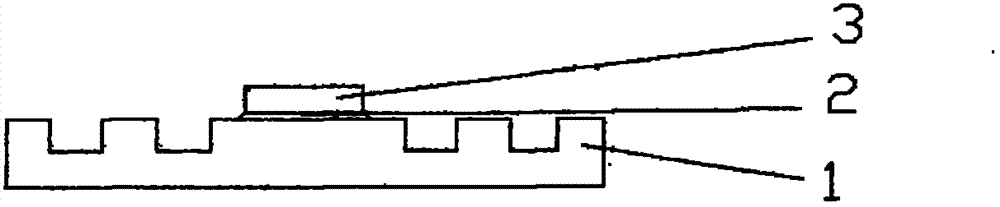

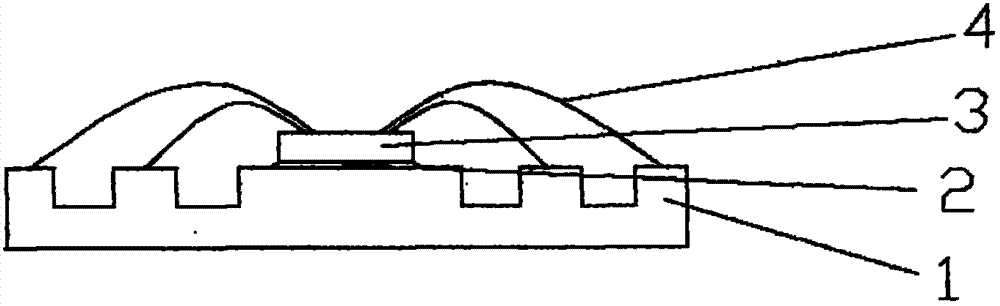

[0027] Firstly, grooves are formed on the frame by corrosion, and then filled by sandblasting and then green paint. The specific manufacturing process is carried out as follows:

[0028] The first step, wafer thinning; wafer thinning thickness is 50μm, roughness Ra 0.10um;

[0029] The second step is to use a double-knife scribing machine and its process for scribing;

[0030] The third step is to use adhesive film to glue the core;

[0031] The fourth step is to use the same method as the conventional AAQFN process for pressure welding;

[0032] The fifth step is to carry out a plastic sealing with traditional plastic sealing compound;

[0033] The sixth step is post-curing in the same way as the conventional AAQFN process;

[0034] The seventh step is to etch the groove on the back of the frame; use ferric chloride solution to do partial window half-etching on the back of the frame to form a groove, and the depth is controlled within half of the thickness of the frame;

...

Embodiment 2

[0038] Firstly, grooves are formed on the frame by corrosion, and then filled by sandblasting and then green paint. The specific manufacturing process is carried out as follows:

[0039] In the first step, the thinning thickness of the wafer is 130μm, and the roughness Ra is 0.20um;

[0040] The second step is to use a double-knife scribing machine and its process for scribing;

[0041] The third step is to use the film (DAF) on the core;

[0042] The fourth step is to use the same method as the conventional AAQFN process for pressure welding;

[0043] The fifth step is to carry out a plastic sealing with traditional plastic sealing compound;

[0044] The sixth step is post-curing in the same way as the conventional AAQFN process;

[0045] The seventh step is to etch the groove on the back of the frame; use ferric chloride solution to do partial window half-etching on the back of the frame to form a groove, and the depth is controlled within half of the thickness of the fra...

Embodiment 3

[0049] Firstly, grooves are formed on the frame by corrosion, and then filled by sandblasting and then green paint. The specific manufacturing process is carried out as follows:

[0050] In the first step, the wafer thinning thickness is 200μm, and the roughness Ra is 0.30um;

[0051] The second step is to use the ordinary QFN scribing process for scribing;

[0052] The third step is to use the film (DAF) on the core;

[0053] The fourth step is to use the same method as the conventional AAQFN process for pressure welding;

[0054] The fifth step is to carry out a plastic sealing with traditional plastic sealing compound;

[0055] The sixth step is post-curing in the same way as the conventional AAQFN process;

[0056] The seventh step is to etch the groove on the back of the frame; use ferric chloride solution to do partial window half-etching on the back of the frame to form a groove, and the depth is controlled within half of the thickness of the frame;

[0057] The eig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com