Electric heating device used for removing motor stator copper wire

An electric heating device, stator copper wire technology, applied in electromechanical devices, manufacturing motor generators, electric components, etc., can solve problems such as full of soot, reduce motor performance, environmental pollution, etc., achieve uniform heating, convenient operation, and clean safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

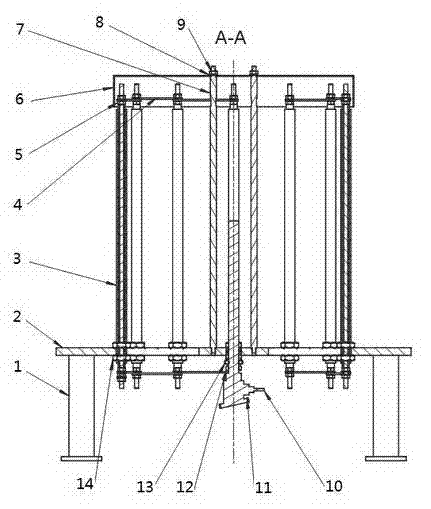

[0011] The present invention will be further described below in conjunction with the drawings:

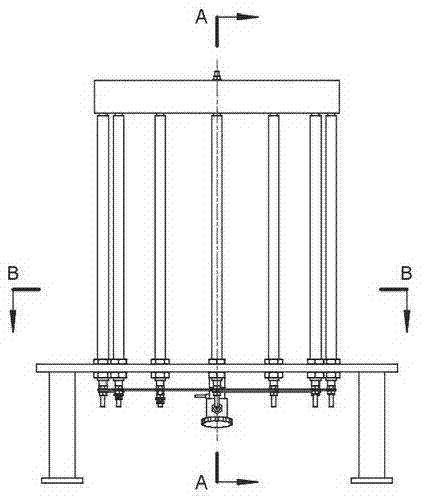

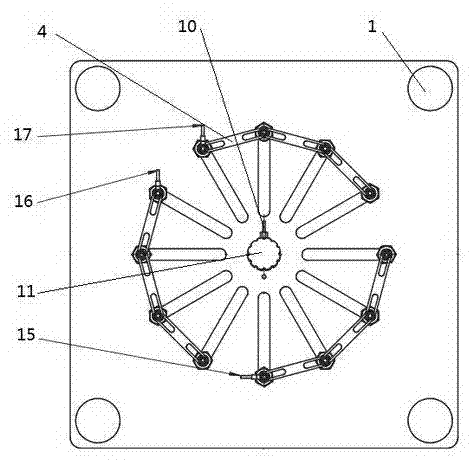

[0012] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention relates to an electric heating device for disassembling the copper wire of a motor stator. It consists of a leg 1, a workbench 2, an elongated hole 18, a positioning wire 19, a heating tube 3, a connecting plate 4, and a nut (5, 9, 14), protective cover 6, fixed rod 7, gasket 8, thermocouple lead wire 10, thermocouple 11, fixed sleeve 12, tightening bolt 13, U phase lead wire 15, V phase lead wire 16, W phase lead It is composed of wiring 17 and other components, and is characterized in that: the workbench 2 is supported by four legs 1, and the workbench 2 is provided with twelve long holes 18, and the twelve heating tubes 3 are respectively fixed in the work with nuts 14 On the table 2, at the same time, the table 2 is engraved with several circular positioning lines 19, which can heat the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com