One-sided matching technology for green house dry fruit trees

A dry and fruit tree technology, applied in horticulture, botanical equipment and methods, gardening tools/equipment, etc., can solve the problems of slow production speed, high planting density, reduced yield, etc., and achieve easy management, high yield and good quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

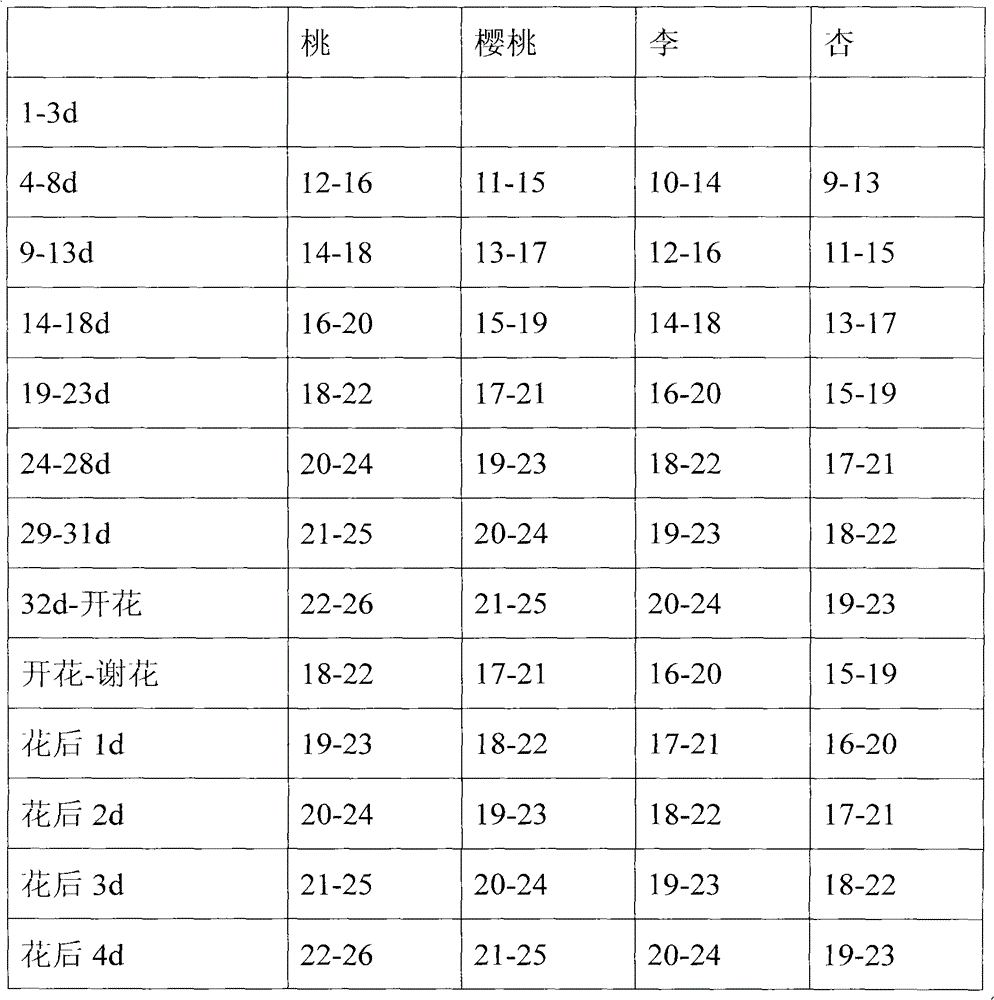

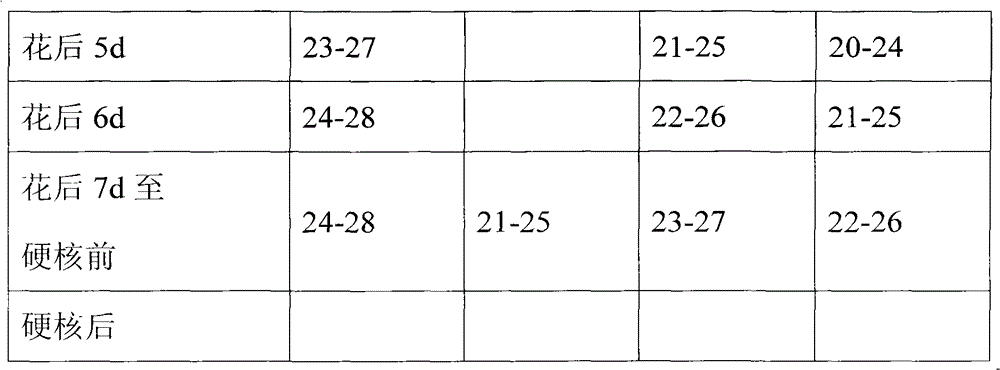

[0017] One-sided supporting technology for dry fruit trees in greenhouses, first prepare seedlings, purchase seedlings before the Spring Festival, wipe off all the buds on the rootstock, cut off the branches, cut the buds flat at 1 cm above the grafting interface, and cut off 20-30 cm from the top of the mature seedlings . Arrange the seedlings in bundles and horizontally in the ditch. The depth of the ditch is 0.6m. The top bundle is about 30cm above the ground. Occupy the land, it must be thoroughly plowed before planting, and then ridged along the row. Before planting, dip the roots with spores and rooting agents, and then cover them with wet thatch for 24 hours. When planting, first plant the seedlings to one side of the ridge, with a plant spacing of 0.8m and a row spacing of 1.8m. The interface for north-south travel is east, and the interface for east-west travel is north. When planting and filling the soil, vibrate up and down like pounding garlic, so that the rhizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com