Making method of powdered palm kernel oil

A technology of palm kernel oil and powdered oil, which is applied in the preparation of powdered oil and palm kernel oil powdered oil. It can solve the problems that sucrose does not have emulsifying properties, so as to broaden the applicability and use range, facilitate transportation, and provide good emulsion Effects of sensory properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] At 55°C, mix and dissolve 9.3% (w / v) food-grade modified starch and 18.6% (w / v) sucrose with distilled water, and add 12% (w / v) melted palm kernel oil to make milk liquid; under the condition of 65°C, the high-speed shearing machine shears and emulsifies at 8000rpm, and shears for 3min; the sheared emulsion is immediately subjected to high-pressure homogenization with a high-pressure homogenizer, and the homogenization pressure is 35Mpa, and the homogenization is performed twice; The homogenized emulsion is spray-dried, the air inlet temperature is 195° C., and the air outlet temperature is 90° C. to obtain the finished palm kernel oil powder oil.

[0020] The food-grade modified starch used is a food-grade esterified modified starch prepared by reacting starch with octenyl succinic anhydride OSA. The food-grade modified starch product used in the present invention is provided by National Starch Shanghai Company.

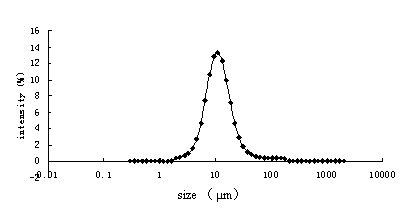

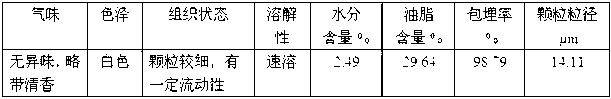

[0021] Table 1 Determination results of physical and c...

Embodiment 2

[0024] At 50°C, mix and dissolve 8.7% (w / v) food grade modified starch and 19.3% (w / v) sucrose with distilled water, and add 13% (w / v) melted palm kernel oil to make milk liquid; under the condition of 60°C, the high-speed shearing machine shears and emulsifies at 9000rpm, and shears for 2.5 min; the sheared emulsion is immediately subjected to high-pressure homogenization with a high-pressure homogenizer, with a homogenization pressure of 35Mpa, and homogenization for 3 times ; The homogenized emulsion is spray-dried, the air inlet temperature is 190° C., and the air outlet temperature is 95° C. to obtain the finished palm kernel oil powder oil.

Embodiment 3

[0026] At 60°C, mix and dissolve 8.5% (w / v) food-grade modified starch and 19.5% (w / v) sucrose with distilled water, and add 12.8% (w / v) melted palm kernel oil to make milk liquid; under the condition of 55°C, the high-speed shearing machine shears and emulsifies at 9500rpm, and shears for 2min; the sheared emulsion is immediately subjected to high-pressure homogenization with a high-pressure homogenizer, and the homogenization pressure is 40Mpa, and the homogenization is performed twice; The homogenized emulsion is spray-dried, the air inlet temperature is 185° C., and the air outlet temperature is 95° C. to obtain the finished palm kernel oil powder oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com