High stability Ni-based phosphide catalyst and its preparation method

A high-stability, catalyst technology, applied in the preparation of hydroxyl compounds, organic compounds, physical/chemical process catalysts, etc., can solve the problems of poor catalyst price stability, achieve good technical effects, improve stability, and reduce acidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

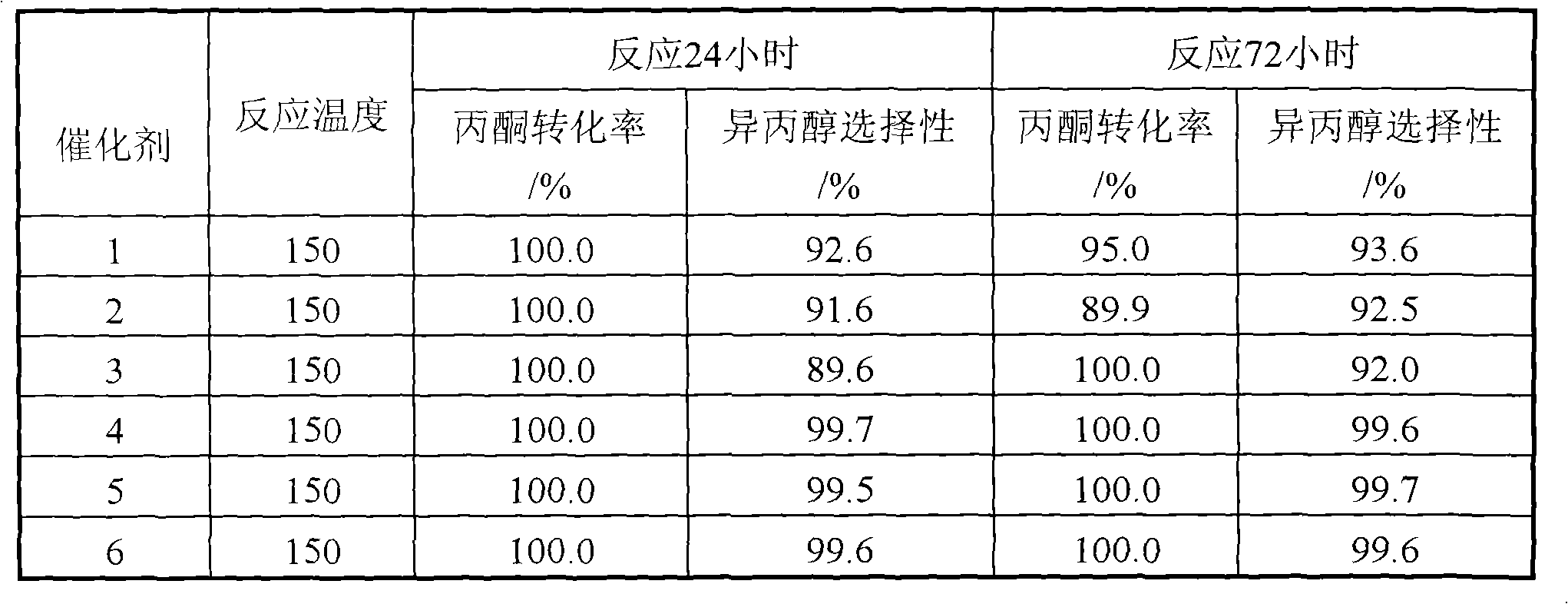

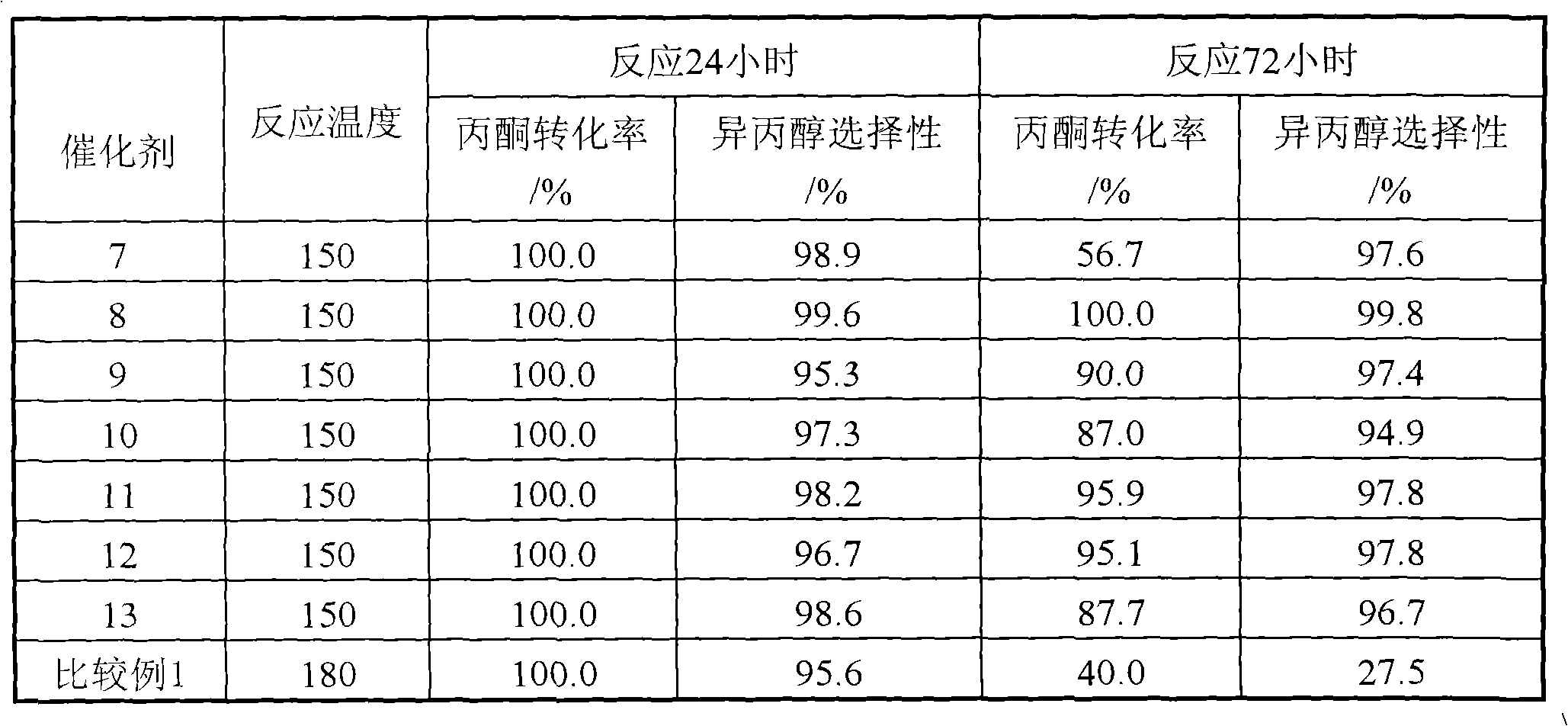

Examples

Embodiment 1

[0025] Take commercially available pseudo-boehmite as Al source, 3% HNO by weight 3 The aqueous solution is used as a binder, and an appropriate amount of Mg is introduced 2+ After extrusion molding, it is dried at 120 ° C and calcined at 600 ° C to obtain a composition of 5% MgO-95% Al 2 O 3 vector.

[0026] Weigh 6.7g Ni (NO 3 ) 2 ·6H 2 O and 2.4g (NH 4 ) 6 Mo 7 O 24 ·6H 2 O 4H 2 O was dissolved in 10.0g distilled water, and a certain amount of 1.7g NH was added. 4 H 2 PO 4 or 2.4g (NH 4 ) 2 H 2 PO 4 , to which concentrated HNO was added dropwise 3 Dissolve the precipitate, and adjust the pH value between 4 and 5 to form solution I; add 3.5 g of citric acid to solution I to form solution II; heat solution II to 70 ° C, add dropwise to 10.0 g of carrier while hot , calcined at 550°C for 8 hours after drying at 120°C. The catalyst was used in H 2 It was reduced at 650°C for 12 hours. The catalyst composition is: 12%NiO-10MoOx-5%POx-3.6%MgO-69.4%Al 2 O 3...

Embodiment 2

[0028] Take commercially available pseudo-boehmite as Al source, 1.5% HNO by weight 3 and 1.5%H 3 PO 4 The solution is a binder, and an appropriate amount of Mg is introduced 2+ After extrusion, it is dried at 120 °C and calcined at 600 °C to obtain a composition of 5% MgO-95% Al 2 O 3 vector. The catalyst preparation method and evaluation conditions are the same as those in Example 1, and the reaction results are shown in Table 1.

Embodiment 3

[0030] The commercially available pseudo-boehmite powder was calcined at 600 ℃ for 4 hours to obtain δ-Al 2 O 3 , take the same amount of δ-Al 2 O 3 With pseudo-boehmite as Al source, 1.5% HNO by weight 3 and 1.5%H 3 PO 4 The solution is a binder, and an appropriate amount of Mg is introduced 2+ , Ca 2+ After extrusion molding, it is dried at 120 °C and calcined at 600 °C to obtain a composition of 5%MgO-5%CaO-90%Al 2 O 3 vector. The catalyst preparation method is the same as that in Example 1. The catalyst preparation method and evaluation method are the same as those in Example 1, and the reaction results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com