Screening device for brickmaking raw materials

A sieving device, raw material technology, applied in the direction of sieving, solid separation, grid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

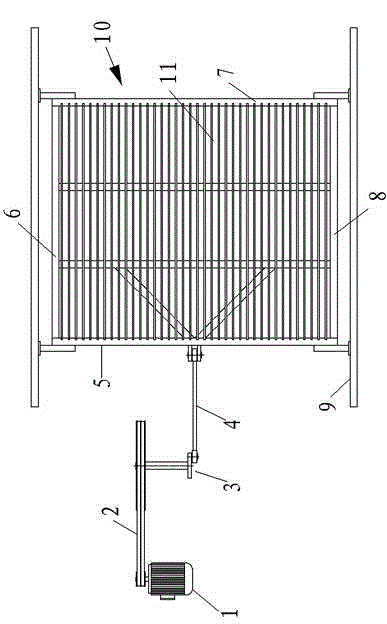

[0017] Such as figure 1 As shown, a brick-making raw material screening device includes a screen frame 10 supporting a screen 11, two juxtaposed slideways 9 extending in the left and right directions and a connecting rod 4, and the two slideways are respectively used to slide and support the screen frame The front and rear sides (8 and 6), one end of the connecting rod is hinged with the left side 5 or the right side 7 of the screen frame, and the other end is hinged with the crank (the crank is specifically driven by the eccentric wheel 3, which is driven by the motor 1 and the belt 2). The rod, the screen frame and the slideway jointly constitute a crank slider mechanism to make the screen reciprocate, and the height of the screen gradually increases or decreases in the left and right directions.

[0018] There are two ways to realize the gradual increase or decrease of the height of the screen:

[0019] The first way: the front and rear sides of the frame are parallel to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com