Bundle of roving yarns, method of manufacturing a bundle of roving yarns and method for manufacturing a work piece

A thick yarn and yarn technology, applied in the field of manufacturing workpieces, can solve the problems of multi-labor and high cost of final products, and achieve the effects of rapid productivity, improved orientation of linear fibers, and rapid impregnation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

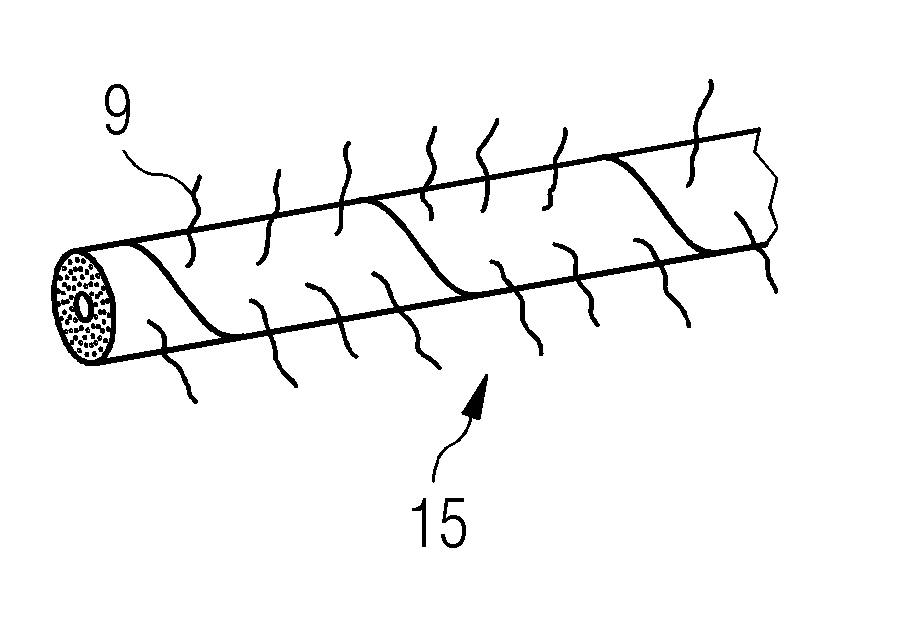

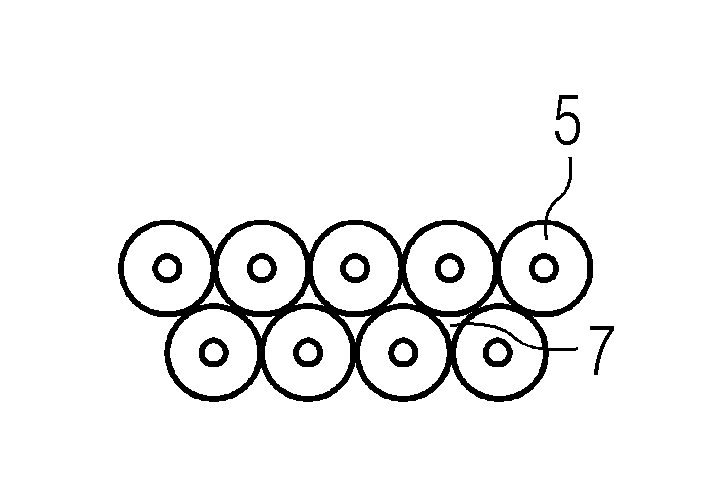

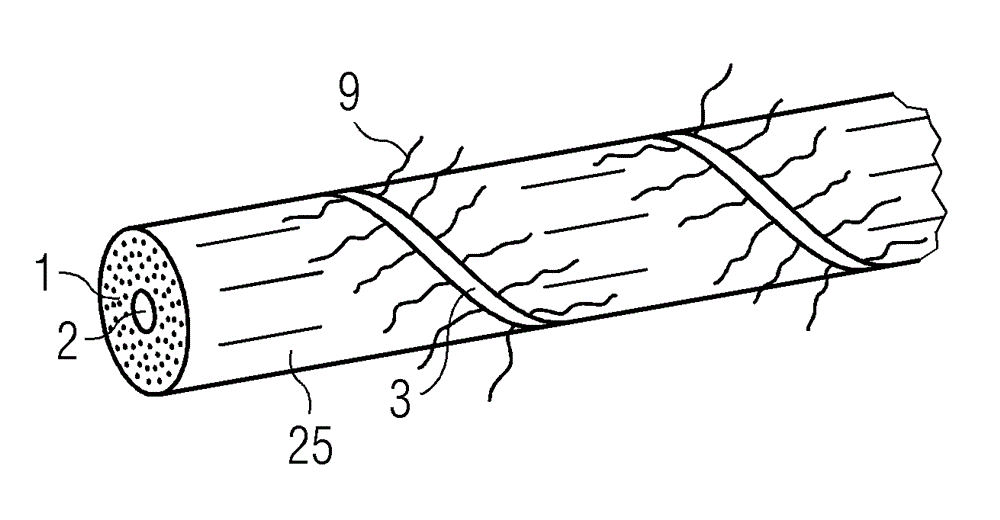

[0040] now refer to Figure 1-6 A first embodiment of the present invention will be described. figure 1 The method of the present invention for producing a roving bundle is schematically shown. A plurality of roving yarns 1 and a central resin flowing yarn 2 are assembled into a roving bundle 5 by means of a winding device 4 . The additional winding yarn 3 is wound circumferentially around a roving bundle 5 by means of a winding device 4 .

[0041] The rovings 1 may comprise glass fibres, carbon fibres, basalt fibres, aramid fibers or natural fibers, for example fibers from wood or plants. Roving yarn 1 comprises longitudinal unidirectional reinforcing fibers. The bundle 5 preferably comprises at least 10, advantageously 10-100 roving yarns 1 . The wrapping yarn 3 may advantageously be an elastic yarn. This causes the bundles 5 to change their circular shape when placed in the mould, allowing all the bundles 5 to fit without air gaps between the bundles. However, it is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com