Multifunctional hydraulic machine

A hydraulic press, multi-functional technology, applied in punching machines, presses, manufacturing tools, etc., can solve problems such as waste, energy consumption of reaction force of master cylinder, etc., to achieve the effect of reducing weight and preventing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

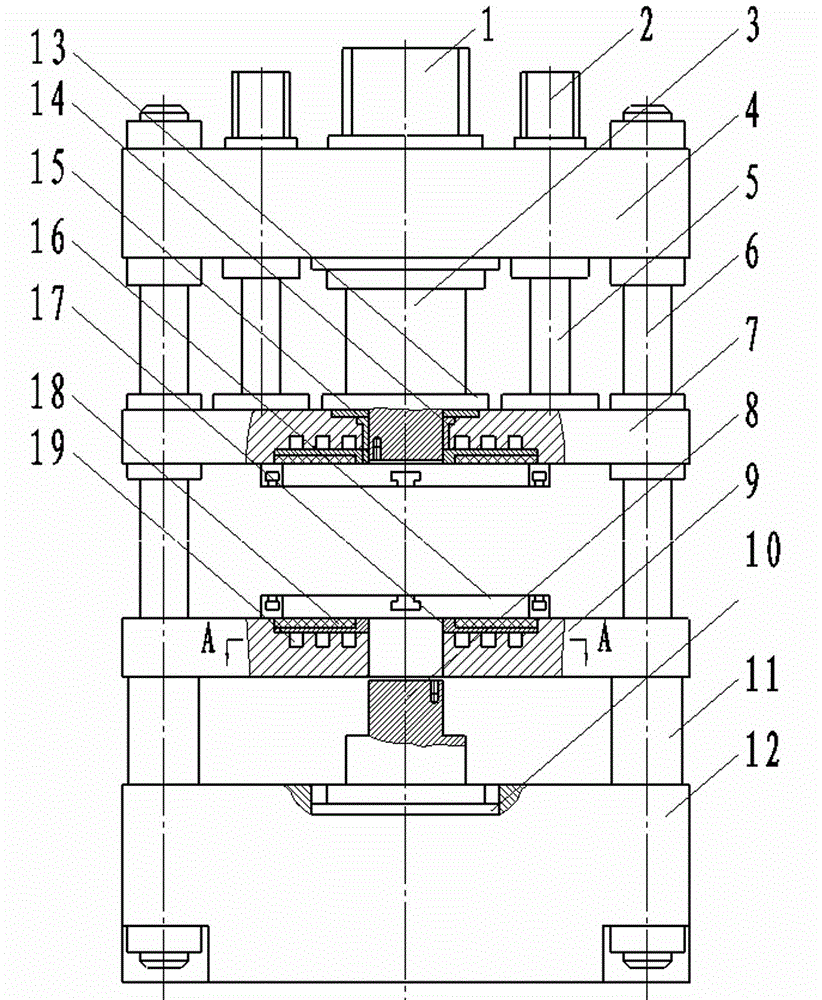

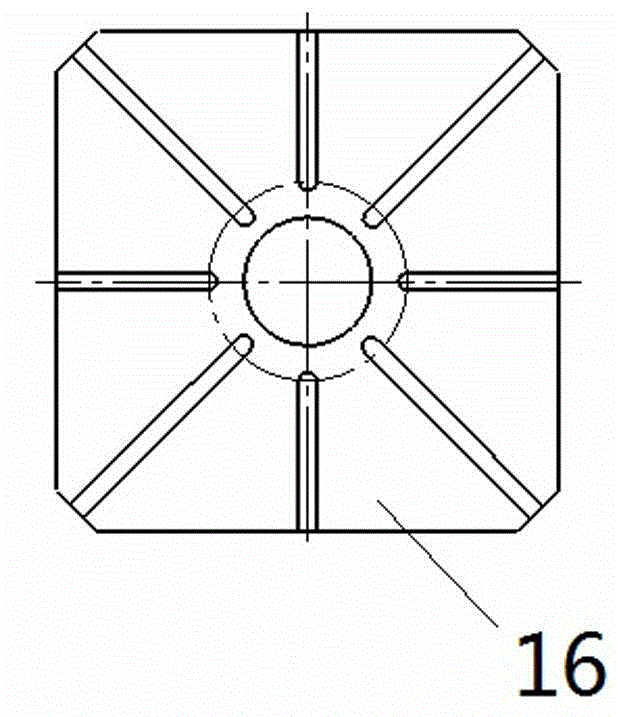

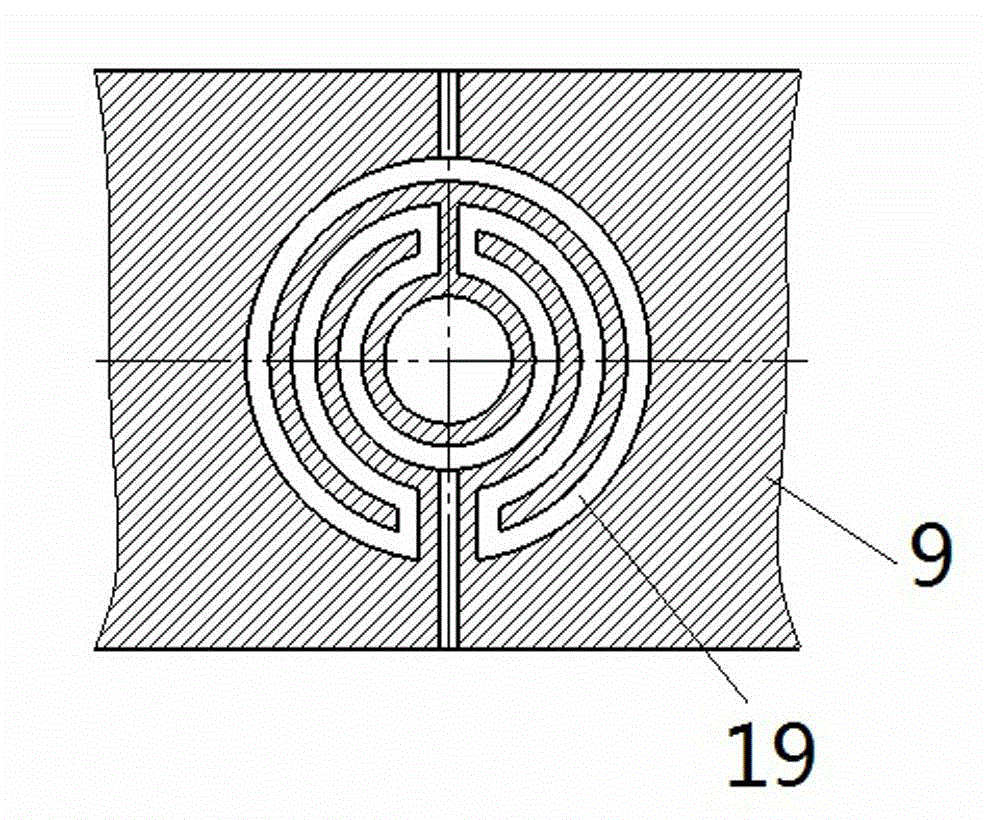

[0024] Embodiment 1 of a kind of multifunctional hydraulic press is as Figure 1~4 Shown: including the column 6, the upper beam 4, the blank holder slider 7, the fixed worktable 9 and the lower beam 12 are arranged at intervals along the vertical direction on the column 6, wherein the upper beam 4, the fixed workbench 9 and the lower beam 12 are connected with the column 6 is fixedly matched, and the blank holder slider 7 is guided and slidably matched with the column 6. The upper beam 4 is provided with a main cylinder 1 and a blank holder cylinder 2. There are four (or two) clamp cylinders and they are circumferentially distributed on the periphery of the master cylinder 1. The blank holder cylinder 2 is fixed to the upper beam 4 The connected blank holder cylinder body and the blank holder cylinder piston 5 fixedly connected with the blank holder slide block 7 . The master cylinder 1 includes a master cylinder body fixedly connected to the upper crossbeam 4 and a master c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com