Overhanging beam structure of frame and vehicle body at rear axle of passenger car

A technology of overhanging beams and rear axles, which is applied in the field of passenger car frames, can solve the problems of increased consumption and complicated manufacturing process of overhanging beams, and achieve the effects of reducing consumption, simplifying processing and structural design, and reducing processing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

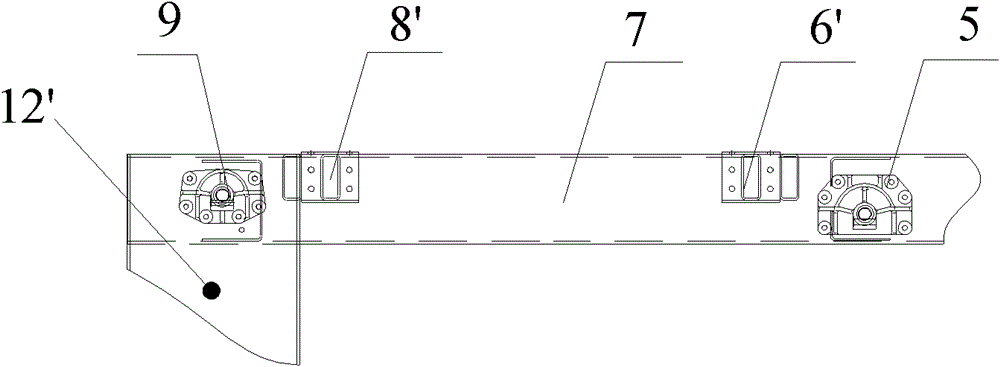

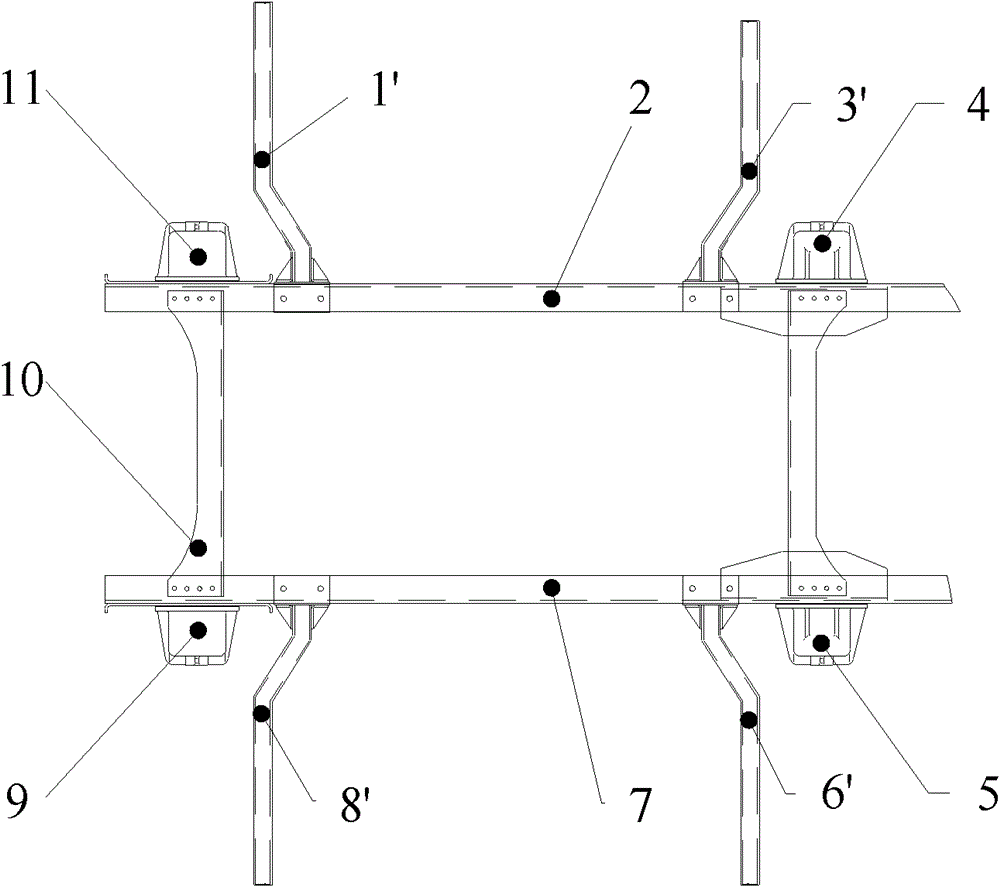

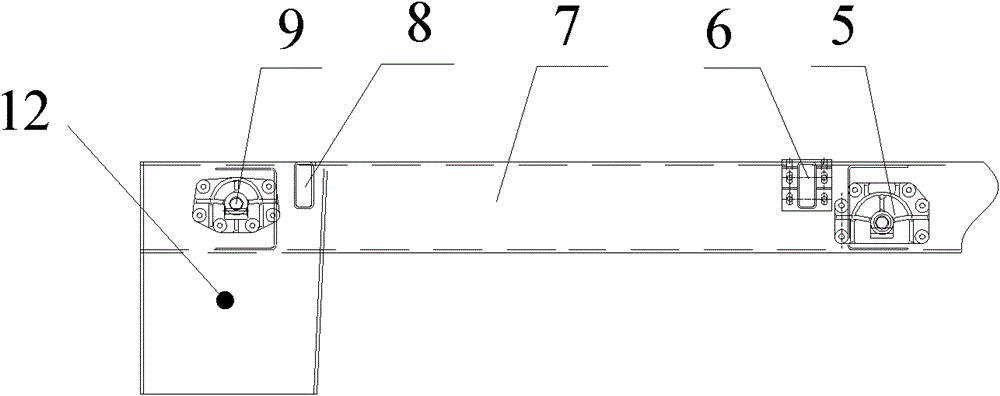

[0025] A kind of outrigger beam structure of frame and vehicle body at the rear axle of passenger car, its structure is as follows: Figure 3-4 As shown, the outrigger structure includes a rear suspension left front wheel overhang beam 1, a rear suspension left rear wheel overhang beam 3, a rear right front wheel overhang beam 8 and a rear right rear wheel overhang beam 6. The overhanging beam 1 of the left front wheel and the overhanging beam 3 of the left rear wheel are arranged on the left longitudinal beam 2 of the rear suspension, wherein the overhanging beam 1 of the left front wheel of the rear suspension is welded and connected to the reinforcing plate 12 of the right-angle structure at the front end, The rear suspension left rear wheel outrigger 3 is connected to the rear suspension left longitudinal beam 2 through bolts. The rear suspension right front wheel overhang beam 8 and the rear suspension right rear wheel overhang beam 6 are arranged on the rear suspension r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com