Scroll casing and clothes drying machine

A dryer and volute technology, applied in household dryers, mechanical equipment, machines/engines, etc., can solve problems such as the close distance between the grille device and the fan, the collision between the grille device and the fan, and the occupation of the internal space of the air duct. , to achieve the effect of simplifying structural design and processing, increasing flexibility, and reducing aerodynamic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

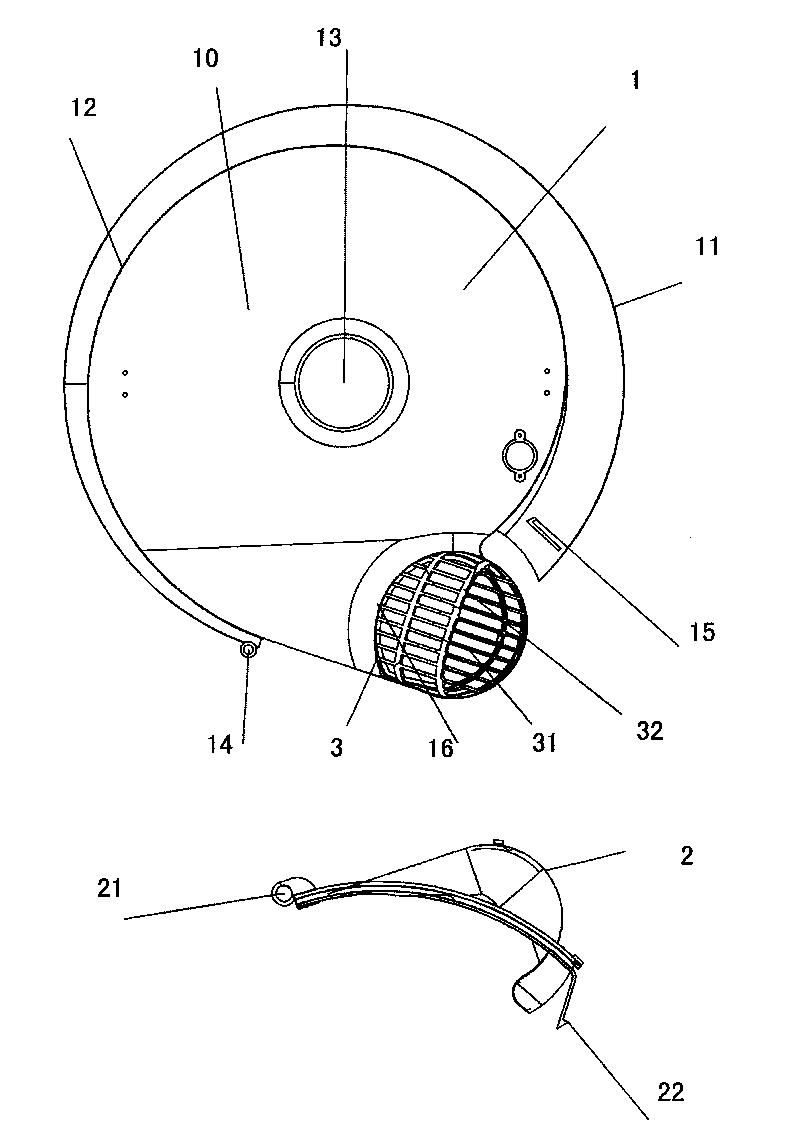

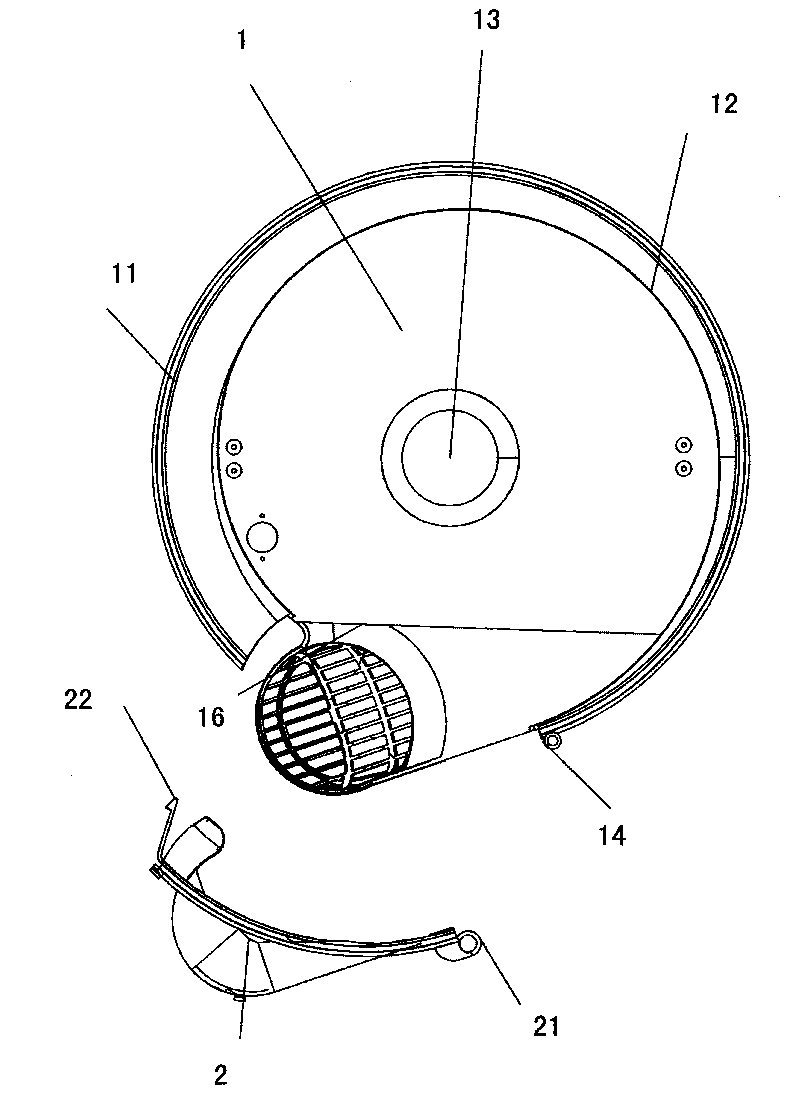

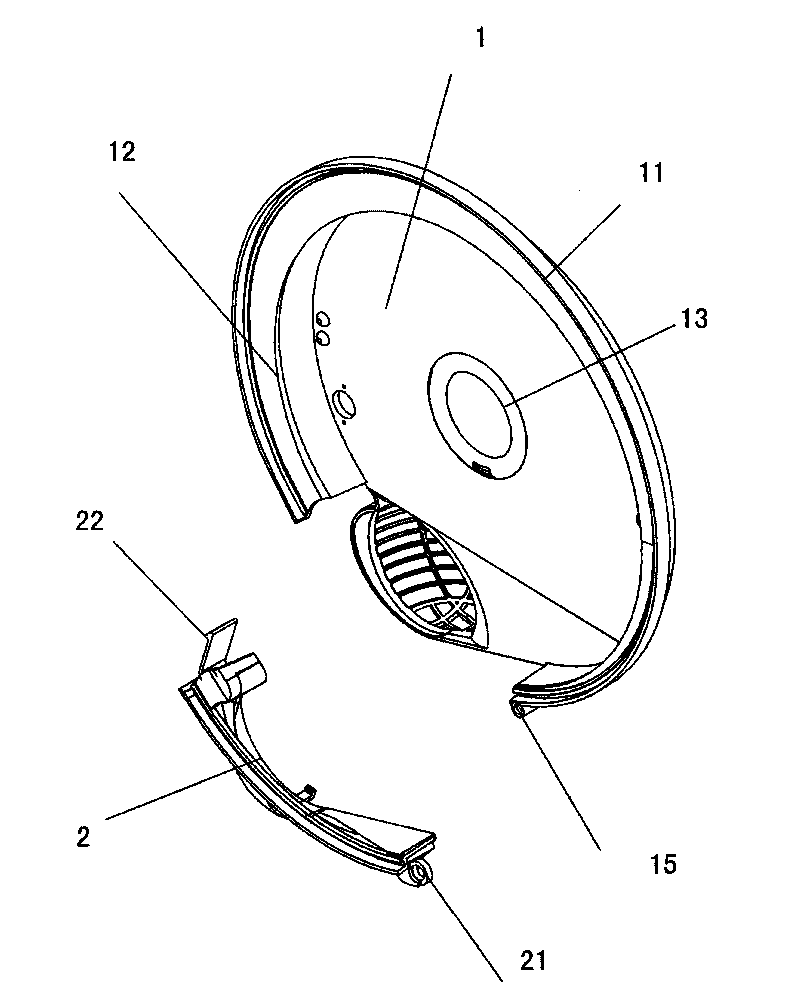

[0024] Such as figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the present embodiment discloses a volute, which includes a base plate 10, a convoluted stepped volute curved surface housing 11, a volute curved surface 12, and an air outlet 16. The inner space of the volute curved surface 12 is an air flow area; wherein, the volute is divided into two or more detachable assemblies, and the assemblies are spliced by a connecting device to form a whole volute ; The two or more assemblies are all plastic structural parts.

[0025] The assembly includes a volute main body 1 and an air outlet joint 2; the volute main body 1 is provided with a bottom plate 10, a convoluted stepped volute curved surface housing 11 and a volute curved surface 12; the volute main body 1 The air outlet 16 of the volute is formed together with the combination of the air outlet joint part 2 .

[0026] The middle part of the bottom plate 10 is provided with a centrifugal fan installation hole 13; the air outlet 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com