Connecting rod expanding-cracking lathe

A connecting rod and machine tool technology, which is applied in the field of connecting rod breaking machine tools, can solve the problems of low bonding quality of the joint surface and complicated processing technology of the connecting rod, so as to simplify the structural design and overall processing technology, and save broaching and grinding Cutting and other processes, the effect of high product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

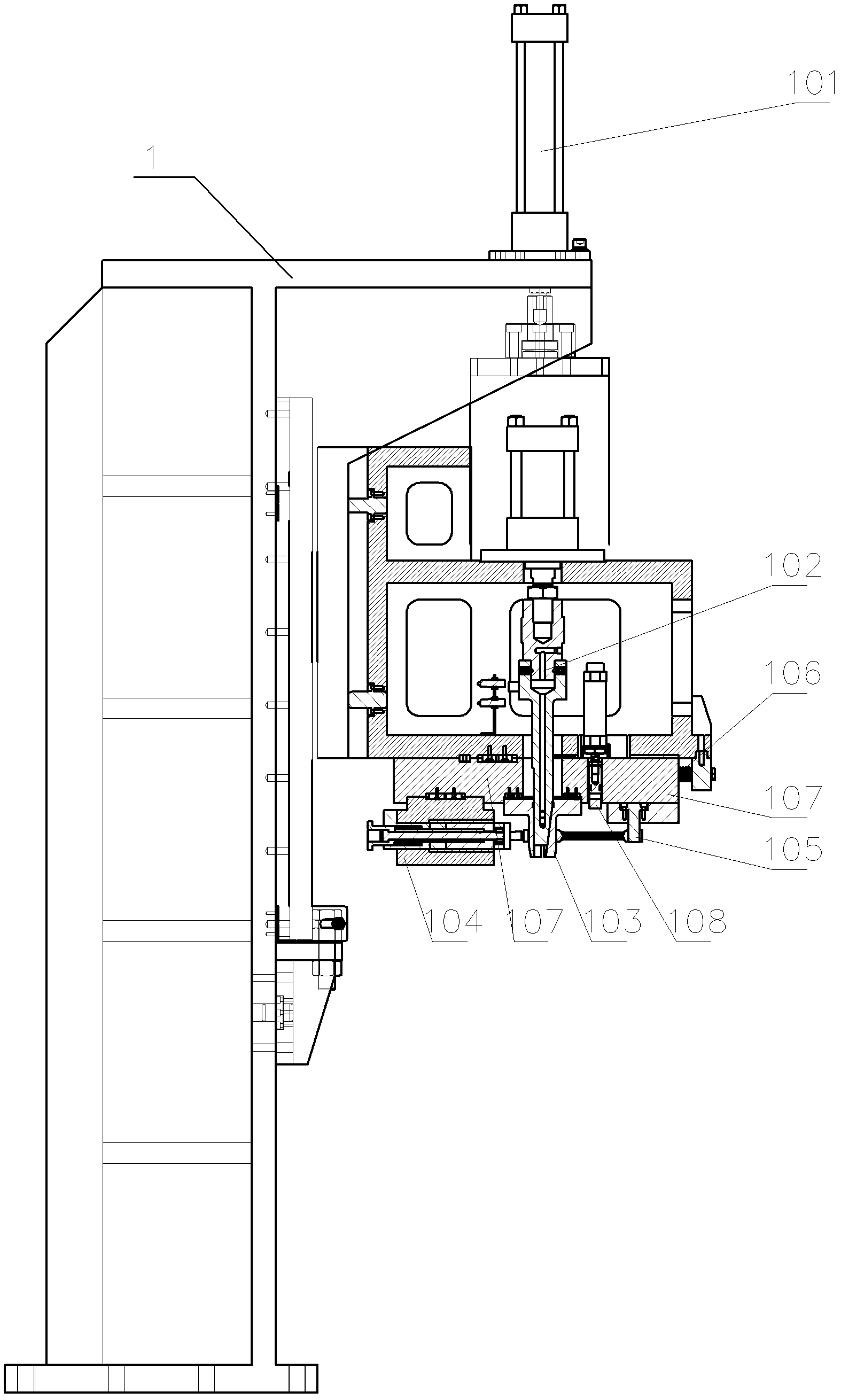

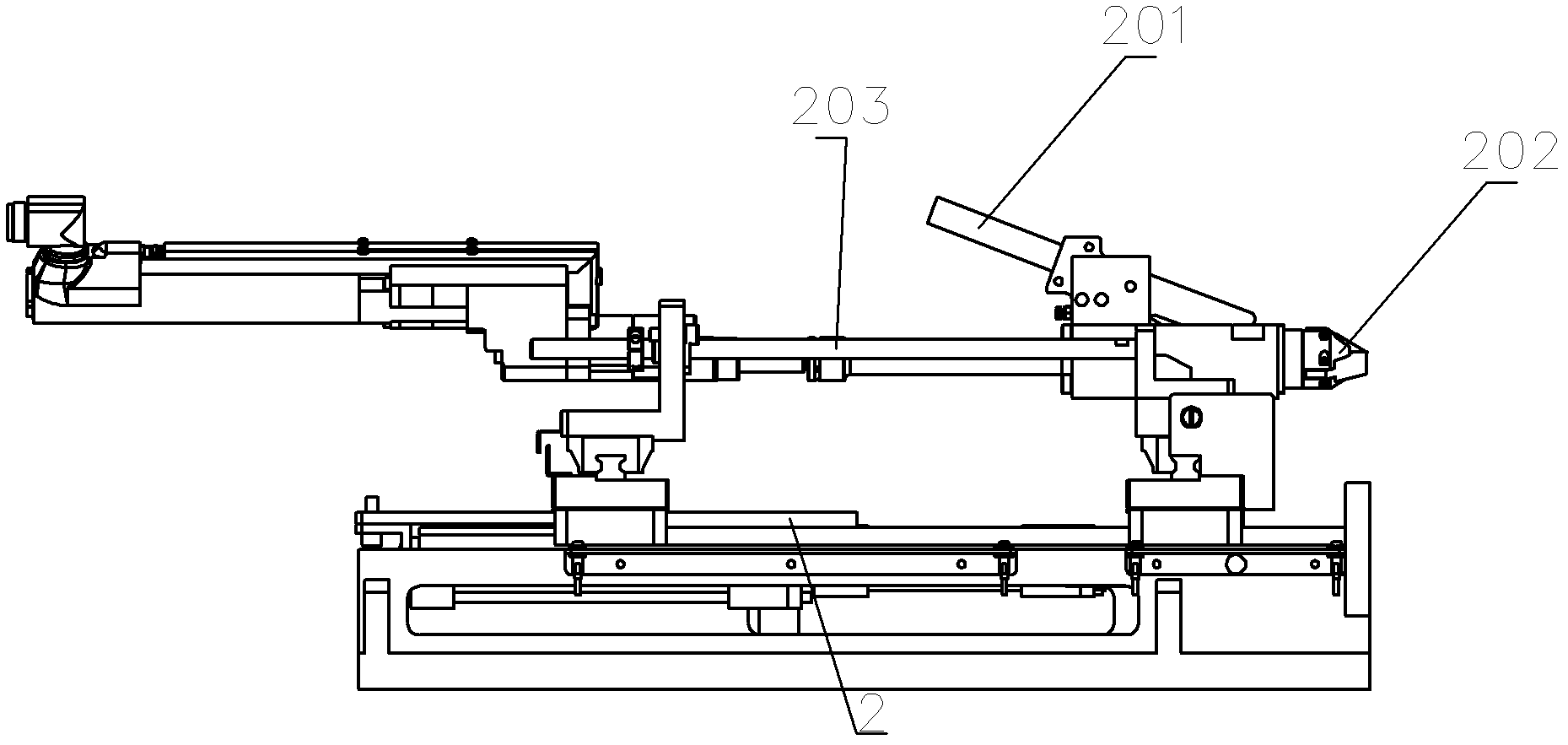

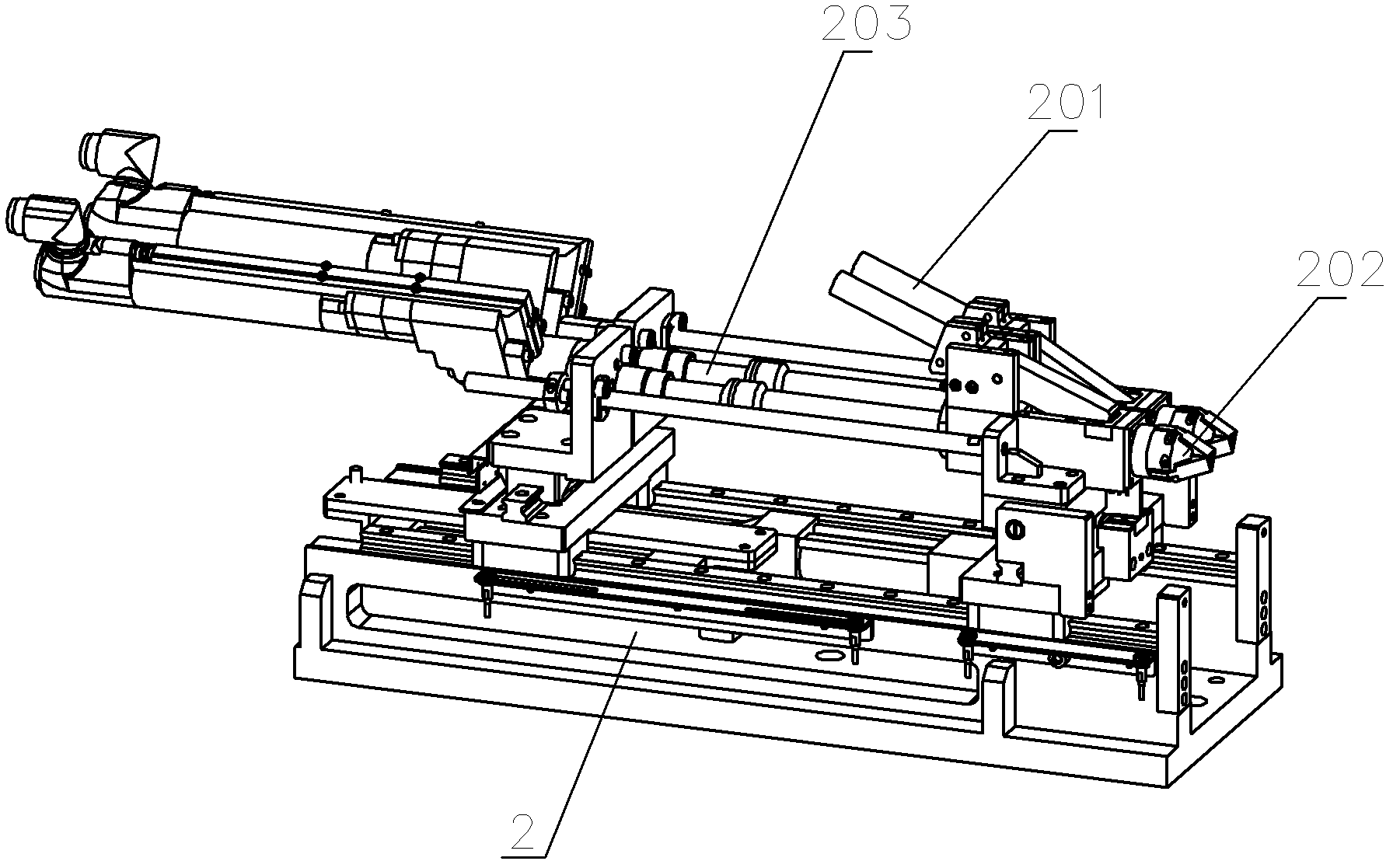

[0029] Such as Figure 1 to Figure 9 Shown, connecting rod breaking machine, including

[0030] Conveyor chain, the conveyor chain is a chain used for the transmission of connecting rod workpieces. The conveying chain is provided with a pallet fixture 9 for fixing the connecting rod workpieces. A stopper device is installed on the conveying chain to facilitate manual loading and unloading of the connecting rods. The feeding position of the connecting rod is also equipped with an organic type identification device and a workpiece presence or absence detection device. After the machine type identification, the equipment can be protected from damage to the key tooling and fixtures such as the equipment and the broken head through the chain control of the PLC;

[0031] As a preferred solution, the pallet fixture 9 includes a bottom plate 91, a first limiting block group 92, and a second limiting block group 93; the first limiting block group 92 is affixed to the bottom plate 91, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com