Improved high efficiency methane tank

A biogas digester and an improved technology, applied in the directions of gas production bioreactors, biochemical instruments, biochemical equipment and methods, etc., can solve the problems of poor garbage degradation ability, uncontrollable temperature, cumbersome process, etc. The effect of accelerating the degradation rate and improving the degradation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below through the implementation manner:

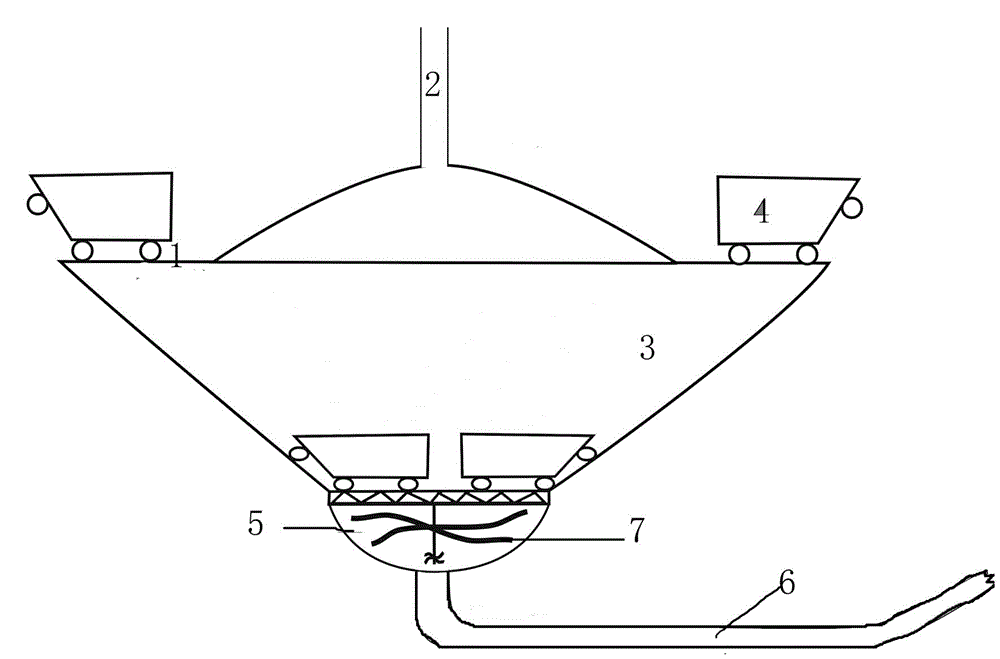

[0023] The improved high-efficiency biogas digester of the present invention comprises a fermentation tank 3 and a net cage 4 with a material inlet and outlet 1 and an air outlet 2. The net cage 4 is used to hold materials, and the net cage 4 is made of a mesh material. The bottom and side meshes are no more than 5 millimeters, and the top meshes are no more than 3 millimeters. During use, the net cage 4 is put into the fermentation tank together with the materials. The setting of the cage can not only prevent the overflow of raw materials, but also facilitate the flow of gas and the leakage of sludge. Fermentation tank 3 sidewalls are provided with slideways, and net cage 4 slides up and down on the slideway by leading mechanism before. Net cage 4 passes in and out of fermenting tank 4 from inlet and outlet 1, in order to facilitate the entering and exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com