Mounting structure and mounting method of air valve seat ring

A technology of valve seat ring and installation structure, which is applied in the direction of valve devices, valve lifts, mechanical equipment, etc., and can solve problems such as unfavorable valve heat dissipation, reduction of the bonding area of valve seat ring holes, and reduced heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below. The following embodiments are only an example of the technical solutions of the present invention, and should not be construed as limiting the protection scope of the present invention.

[0025] Valve seat ring installation structure

[0026] Existing internal combustion engines / engine assemblies mainly include engine blocks, cylinder heads and valves. The cylinder head is fixed to the engine body and has an air passage 12 .

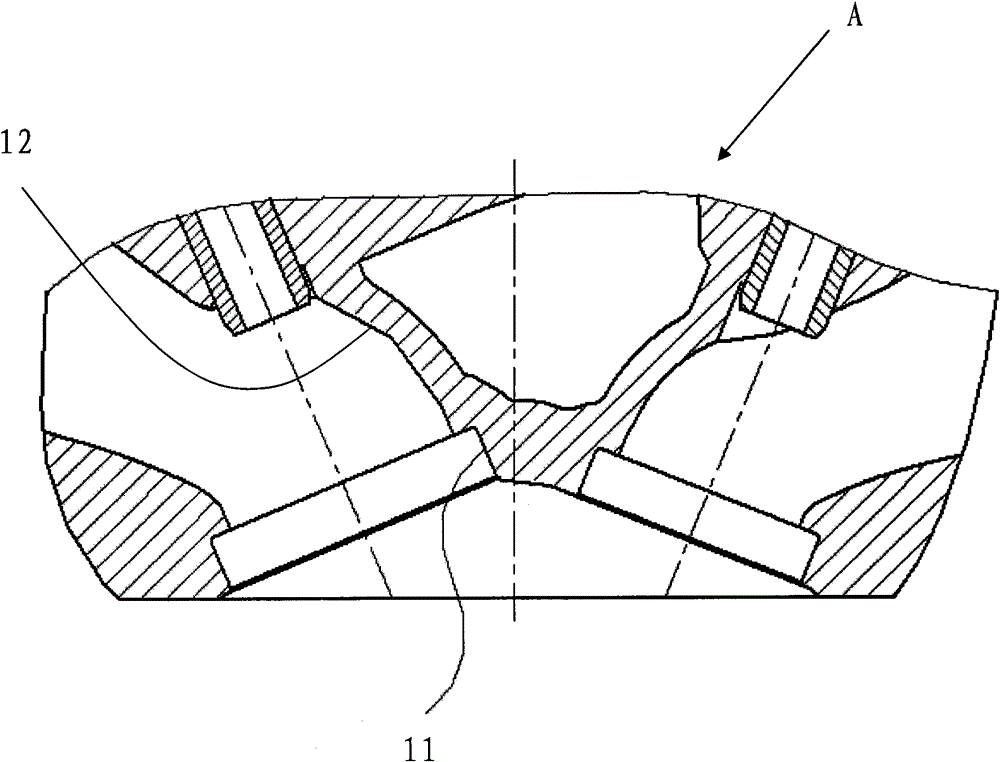

[0027] Such as figure 1 As shown, the structure of the cooperation between the cylinder head A of the internal combustion engine / engine assembly and the valve seat ring is: processing is performed at the joint (air outlet) between the air passage 12 of the cylinder head A and the engine combustion chamber to form a stepped valve seat ring hole 11 .

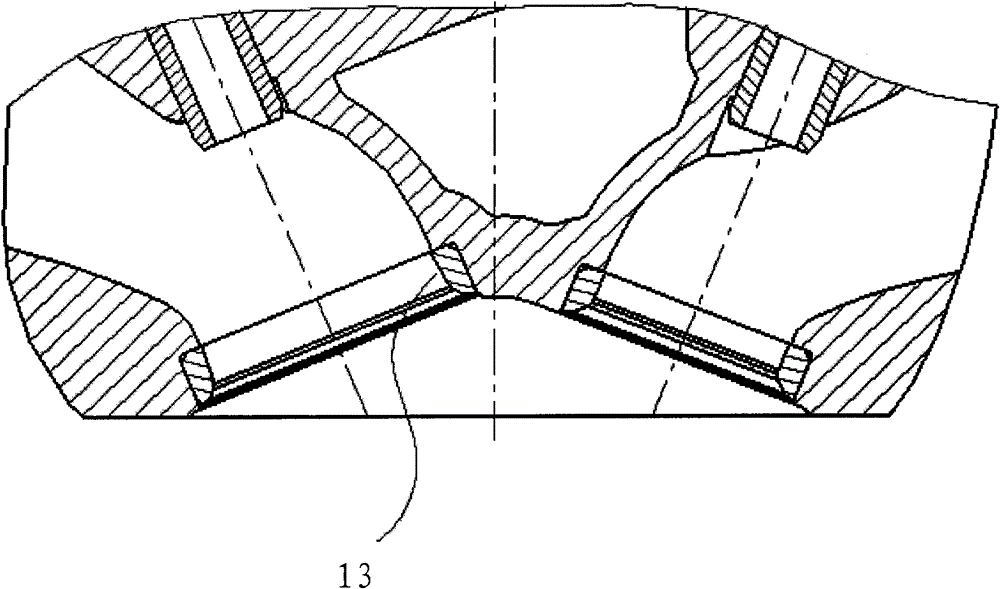

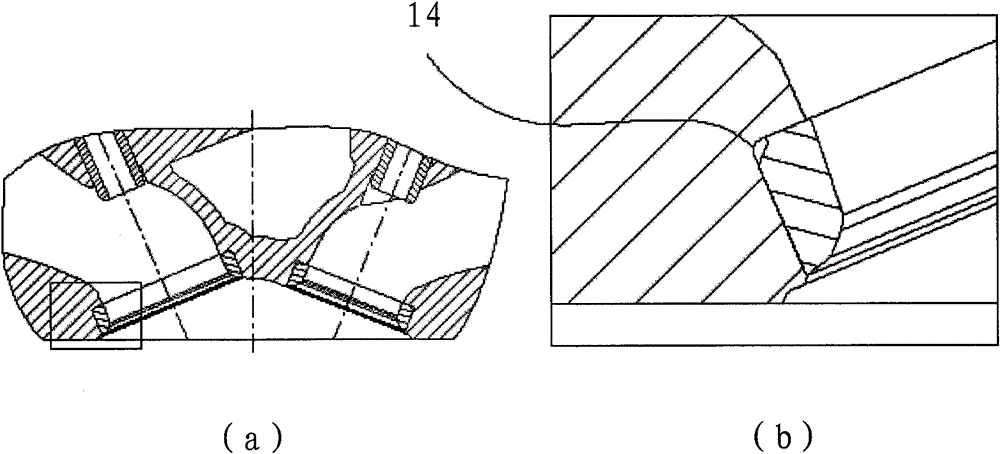

[0028] Therefore, the valve seat mounting structure of the present embodiment is as follows: Figure 4 As shown, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com