Power generation method and device of H-bridge

A technology of power generation device and buffer device, applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of difficult breakthrough in water energy utilization efficiency, depletion of water conservancy power generation resources, and difficulty in development and utilization, etc., to achieve water energy utilization. High efficiency, low cost and low water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

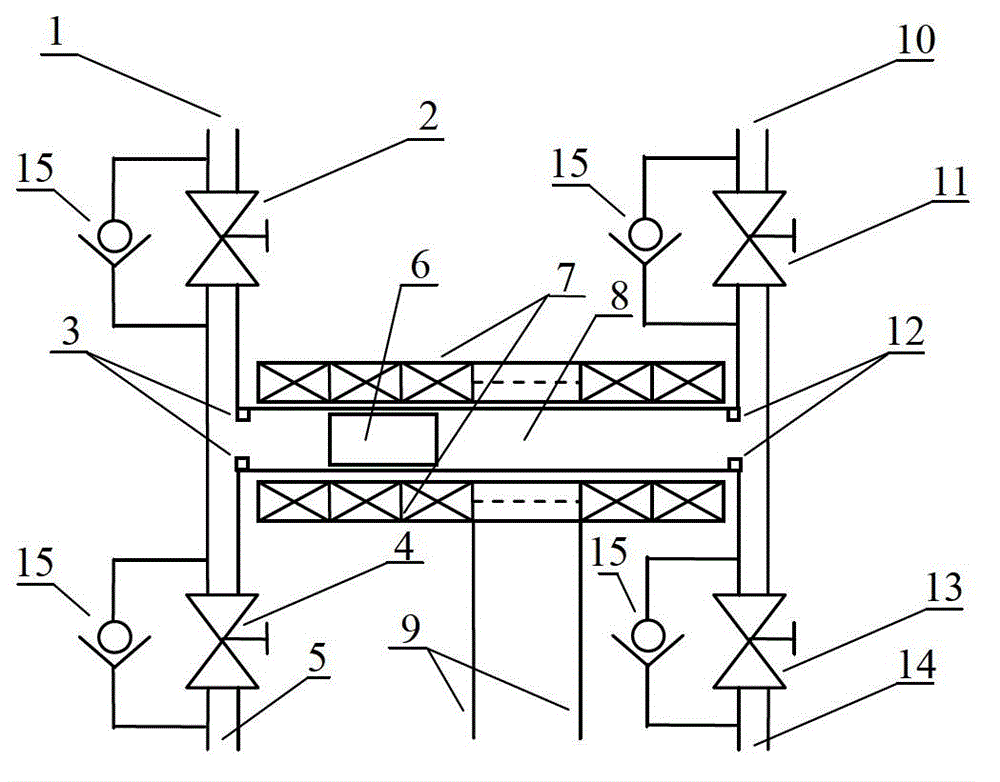

[0019] An H-bridge power generation device, including an H-bridge-type waterway pipeline, a permanent magnet piston (rotor) 6 and a stator coil 7; the H-bridge-type waterway pipeline includes a left bridge arm, a right bridge arm, and a bridge arm passage 8. The left bridge arm The two ends of the left bridge arm are the left bridge arm water inlet 1 and the left bridge arm water outlet 5, the right bridge arms are respectively the right bridge arm water inlet 10 and the right bridge arm outlet 14, and the left bridge arm water inlet 1 entrance The left bridge arm upper solenoid valve 2 is installed, the left bridge arm lower solenoid valve 4 is installed at the outlet of the left bridge arm water outlet 5, the right bridge arm upper solenoid valve 11 is installed at the entrance of the right bridge arm water inlet 10, and the right bridge The right bridge arm lower solenoid valve 13 is installed at the outlet of the arm water outlet 14; the left limit buffer device 3 and the ri...

Embodiment 2

[0023] The principle is the same as that in embodiment 1. A single-phase rectifier bridge is added at both ends of the stator coil outlet 9 and a larger capacitor is connected in parallel in the output section to obtain a DC voltage output; if the single-phase or three-phase inverter bridge is connected in series, single-phase or three-phase inverter bridges can be obtained. Phase alternating current, voltage and frequency can be adjusted as required.

Embodiment 3

[0025] The principle is the same as in Example 1. When the pipe diameter is increased to increase the water flow and output power, the left bridge arm upper solenoid valve 2, the left bridge arm lower solenoid valve 4, the right bridge arm upper solenoid valve 11, and the right bridge arm lower The solenoid valve 13 is replaced with an electric valve or other large flow control valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com