Wind energy heating device of airfoil fan with vertical shaft

A vertical axis, wind energy technology, applied in the direction of wind power generation, wind turbines, wind motor combinations, etc., can solve the problems of high start-up wind speed, high maintenance cost, and large operating noise of horizontal axis wind turbines, so as to improve wind energy utilization efficiency, material The effect of low strength requirements and low start-up wind speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

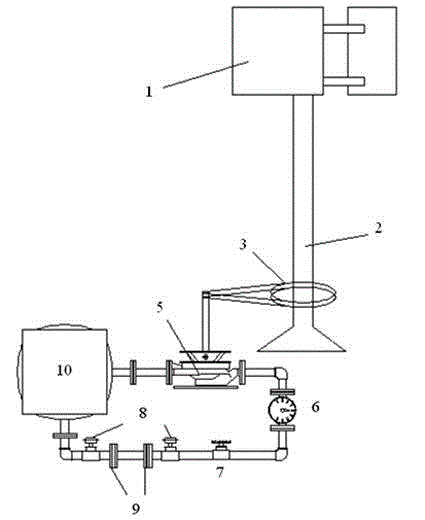

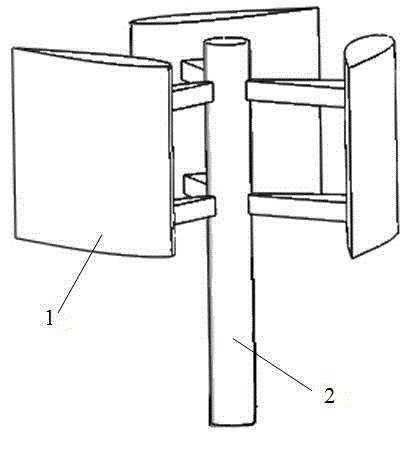

[0022] Such as figure 1 As shown, the wind energy heating device of the vertical axis airfoil fan according to the present invention is provided with a vertical axis airfoil wind turbine, the vertical axis 2 of the wind turbine passes through a transmission mechanism with a belt and a pulley 3 and a centrifugal pump 5 The shaft is connected; the centrifugal pump 5 is located in a circulation pipeline of hydraulic oil: that is, the circulation pipeline is provided with an oil tank 10, a centrifugal pump 5, a flow meter 6, a shut-off valve 7, a first pressure gauge 8, The first throttle orifice 9, the second throttle orifice 9 and the second pressure gauge 8 are connected back to the oil tank 10 from the second pressure gauge 8 to form the circulation pipeline. Shown in label 4 is the base of the wind turbine ( Figure 4 ).

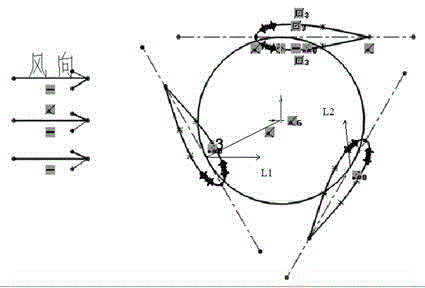

[0023] Cooperate see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com