Electromagnetic four-way reversing valve

A four-way reversing valve and electromagnetic technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of increased valve body volume, complex structure, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

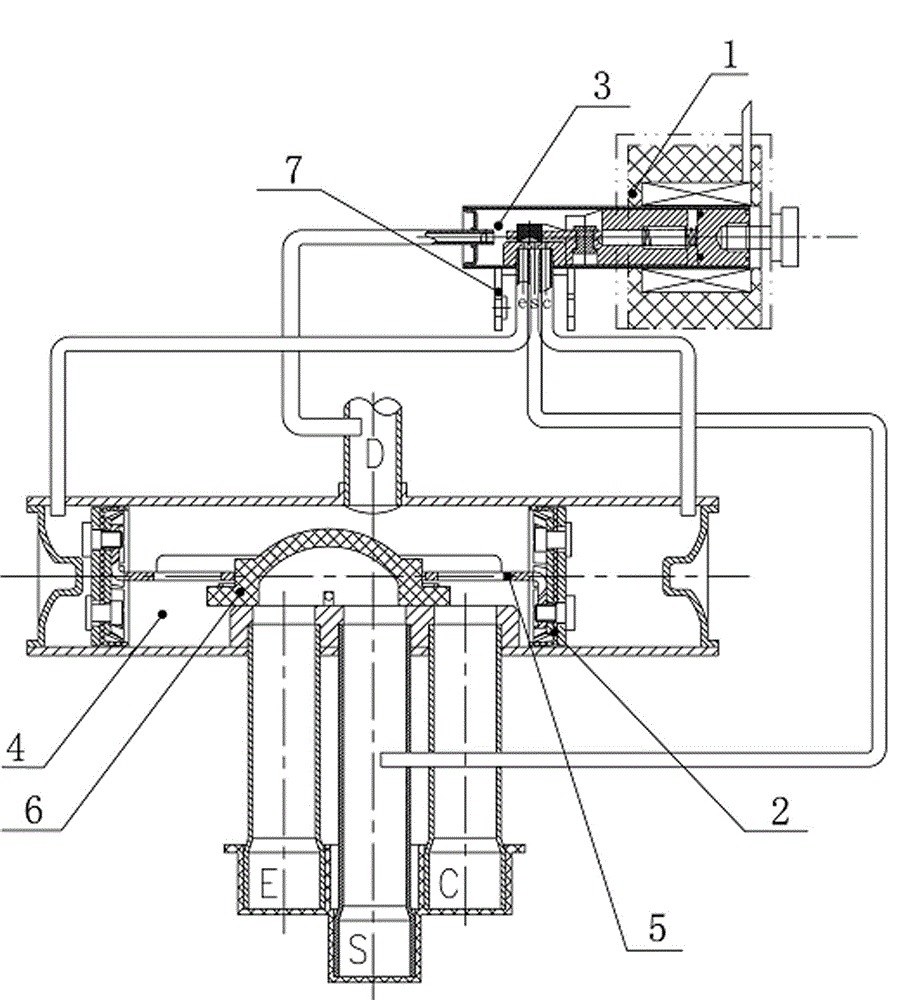

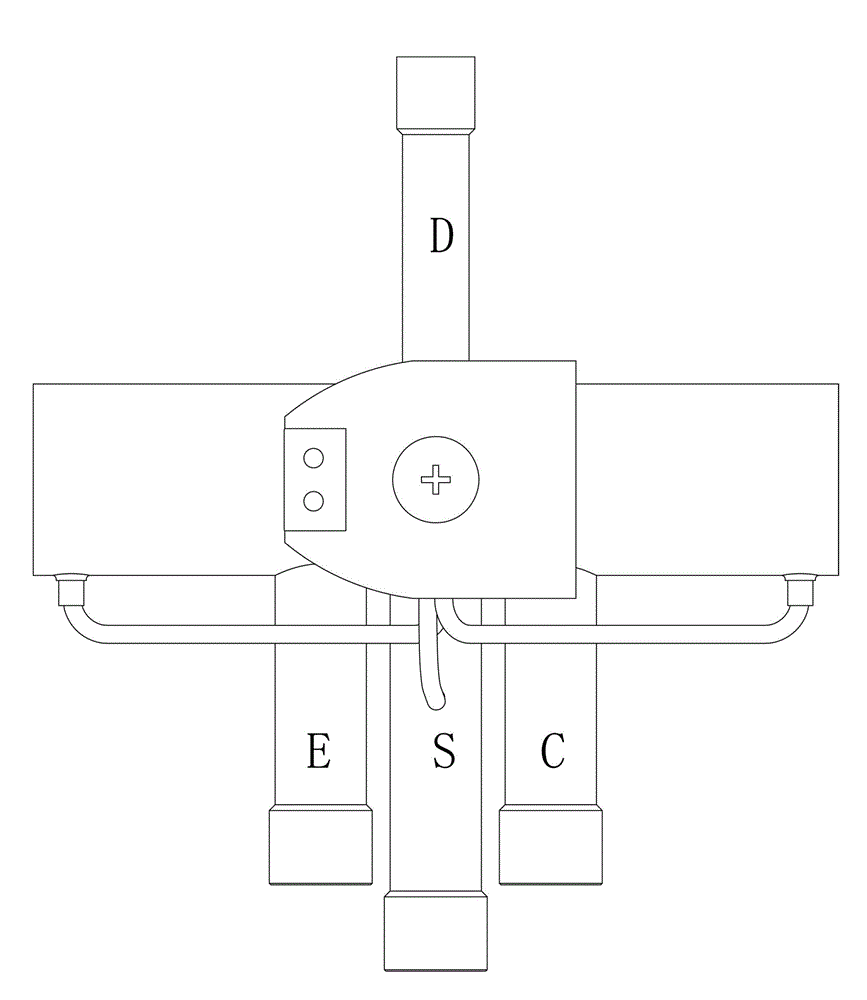

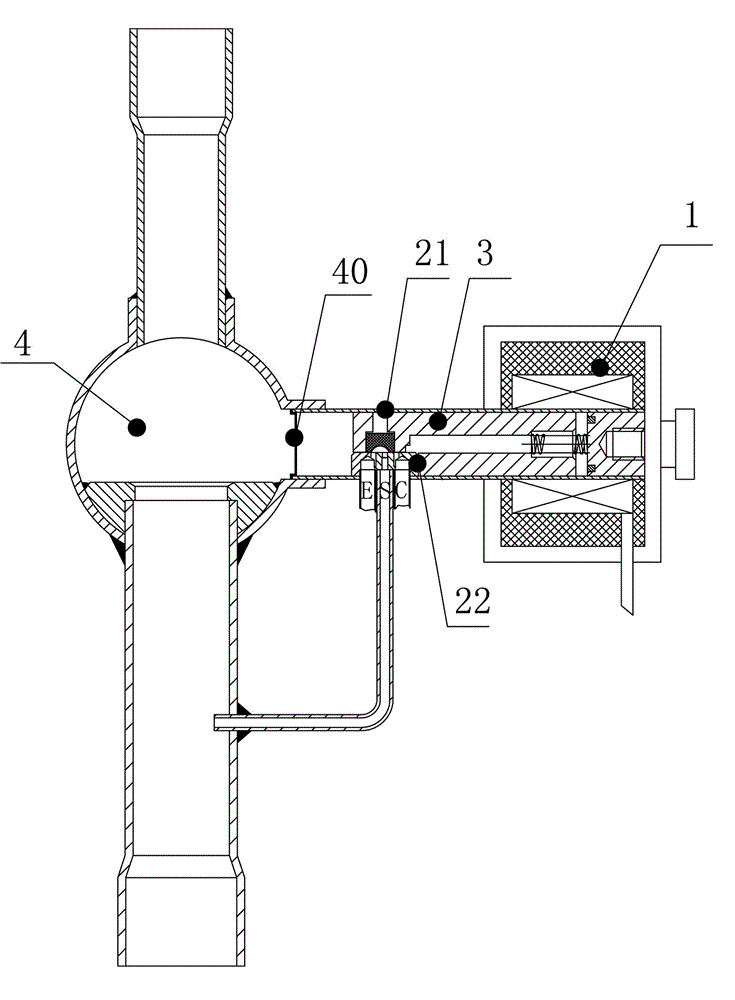

[0032] see first figure 2 and image 3 As shown, a reversing valve includes a main valve body 4, a pilot valve 3 and an electromagnetic coil 1. The main valve body 4 is also provided with a conduit installation hole 60 for installing the pilot valve conduit 21, and the pilot valve 3 cancels the The brass pilot valve 3 has a structure, and the main valve body 4 and the pilot valve 3 are connected and fixed by directly welding the pilot valve conduit 21 in the conduit installation hole 60 on the main valve body 4 .

[0033] next combine Figure 5 As shown, the conduit installation hole 60 of the pilot valve conduit 21 is processed and formed by flanging and stretching.

[0034] The conduit installation hole 60 on the main valve body 4 and the pilot valve conduit 21 are welded together by argon arc welding or other welding methods. A filter net structure 40 is provided at the top, and the filter net structure 40 and the pilot valve conduit 21 are fixed together by welding or ...

Embodiment 2

[0038] see first figure 2 and image 3 As shown, a reversing valve includes a main valve body 4, a pilot valve 3 and an electromagnetic coil 1. The main valve body 4 is also provided with a conduit installation hole 60 for installing the pilot valve conduit 21, and the pilot valve 3 cancels the The brass pilot valve 3 has a structure, and the main valve body 4 and the pilot valve 3 are connected and fixed by directly welding the pilot valve conduit 21 in the conduit installation hole 60 on the main valve body 4 .

[0039] next combine Figure 5-7 As shown, the conduit installation hole 60 of the pilot valve conduit 21 is processed and formed by flanging and stretching.

[0040]The conduit installation hole 60 on the main valve body 4 and the pilot valve conduit 21 are welded together by argon arc welding or other welding methods; The connection part 50 is processed from the same material as the main valve body 4 and the pilot valve conduit 21 . During installation, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com