Novel connecting pipe

A connecting pipe, a new type of technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of easy falling, wear and aging, water shortage and guide failure, etc., to achieve convenient connection, The effect of ensuring safety and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

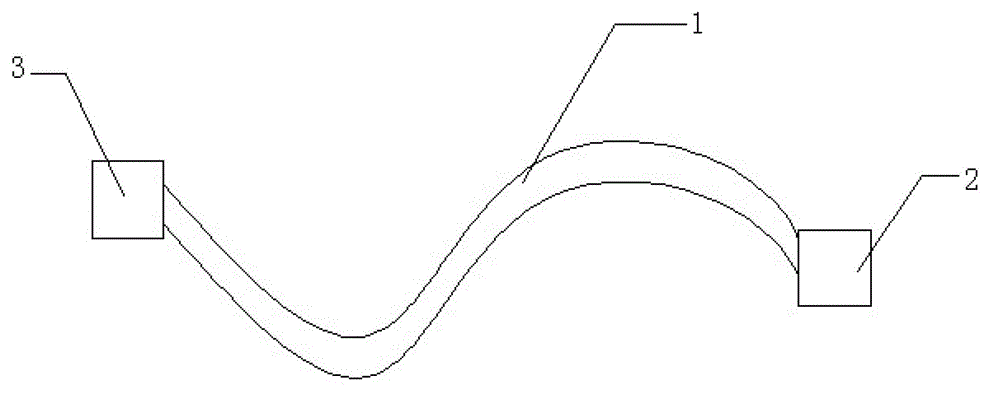

[0014] A new connecting pipe provided in this embodiment has a structure such as figure 1 As shown, it includes a tube body 1 and two quick connectors, the two quick connectors are respectively a proximal quick connector 2 and a distal quick connector 3, and the proximal quick connector 2 and the distal quick connector 3 are respectively fixed on both ends of the tube.

[0015] Wherein, the pipe body 1 is a metal hose, and the specification of the metal hose is from 3mm to 150mm, which is determined according to actual needs. Metal hose has good flexibility, corrosion resistance, high temperature resistance, wear resistance and tensile resistance.

[0016] The proximal quick connector 2 and the distal quick connector 3 are lever-type quick connectors, and the lever-type quick connectors are stainless steel lever-type quick connectors, brass lever-type quick connectors, aluminum alloy lever-type quick connectors Connector or plastic wrench type quick connector. The caliber o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com