Light-emitting diode (LED) lamp module capable of packaging LED chip on radiating supporting carrier circuit and method

A technology of LED chips and LED lamps, which is applied to circuits, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of long production time, cumbersome production process, slow heat conduction, etc., and achieve simple and efficient manufacturing process. , cheap manufacturing process, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

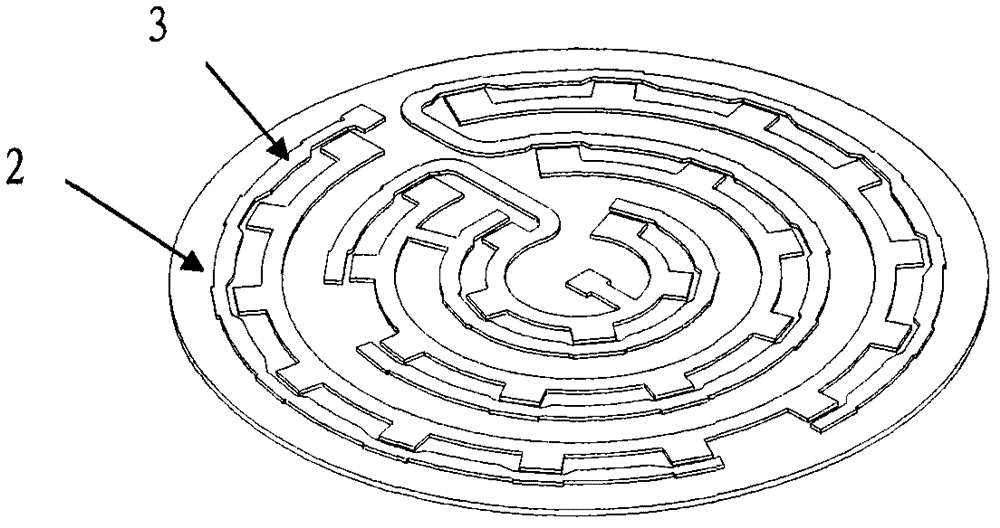

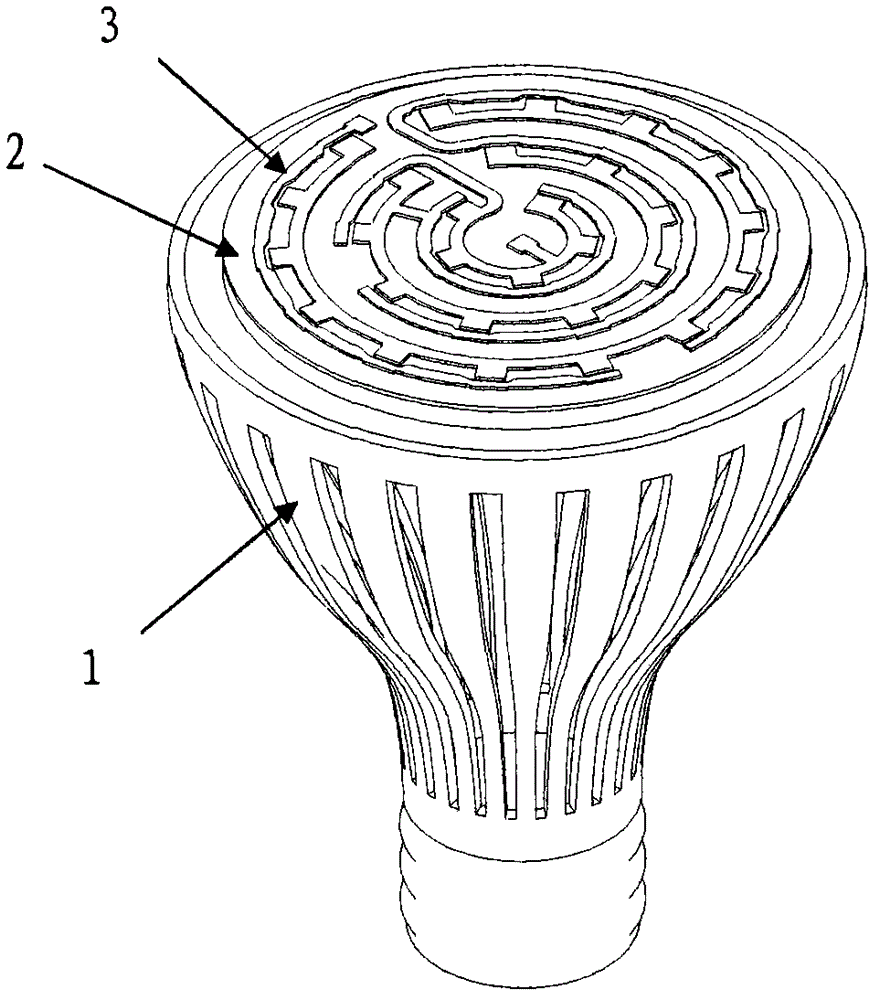

[0038] Next, according to a preferred embodiment of the present invention, adopt COB (Chip On Board) technology to bond the LED chip 4 on the image 3 The three-dimensional heat sink shown is supported on the lamp carrier circuit. An exemplary specific embodiment involved is as follows:

[0039] to clean image 3 The three-dimensional heat dissipation support lamp carrier circuit shown → drip adhesive glue on the three-dimensional heat dissipation support lamp carrier circuit → paste the LED chip 4 and dry it, and then bond the LED chip 4 (such as Figure 4 shown)→Test→Sealing 5 (such as Figure 5 shown)→cure→test→storage, so as to get Figure 5 The shown LED lamp module directly encapsulates the LED chip 4 on the carrier circuit of the three-dimensional heat dissipation supporting lamp.

[0040] in, Figure 4 In order to directly bond the LED chip 4 on image 3 The schematic diagram of the three-dimensional cooling support lamp carrier circuit shown. Figure 5For the L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com