Method for measuring shearing area of rock structral plane in direct shear test

A technology of shear area and measurement method, applied in the direction of measurement device, using stable shear force to test material strength, instrument, etc., can solve the problem that the contour part contains non-entire squares, unsuitable rock mass test sample measurement, work efficiency It can improve the measurement accuracy and work efficiency, improve the test work efficiency and measurement accuracy, and achieve the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

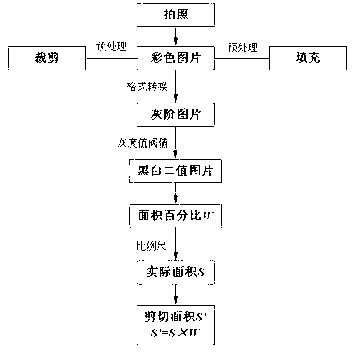

[0053] The measurement method of the shear area in the direct shear test of the rock mass structural surface provided by the invention, see Figure 1 to Figure 9 , including the following steps:

[0054] (1) Photo collection of structural surface of rock mass:

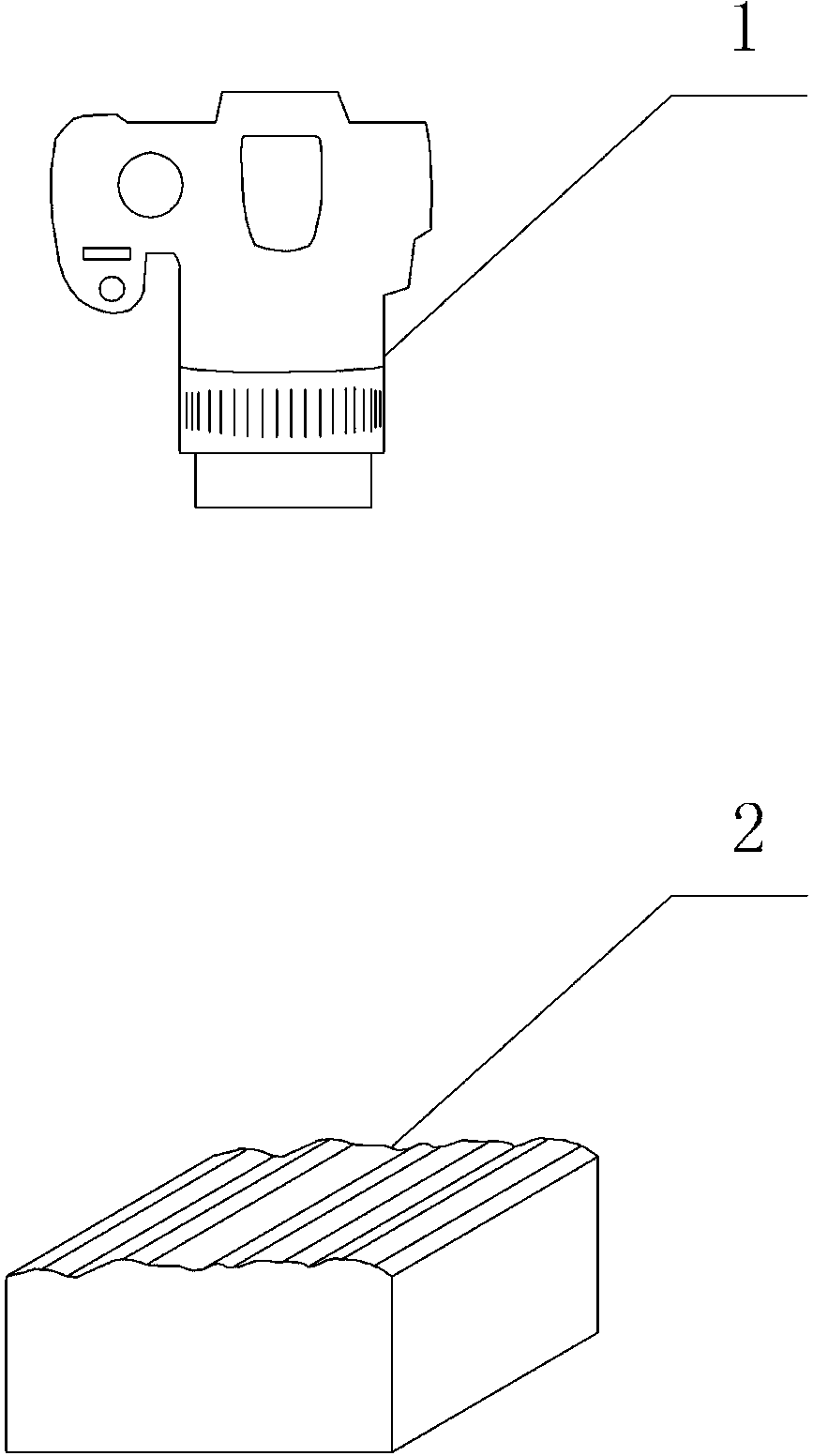

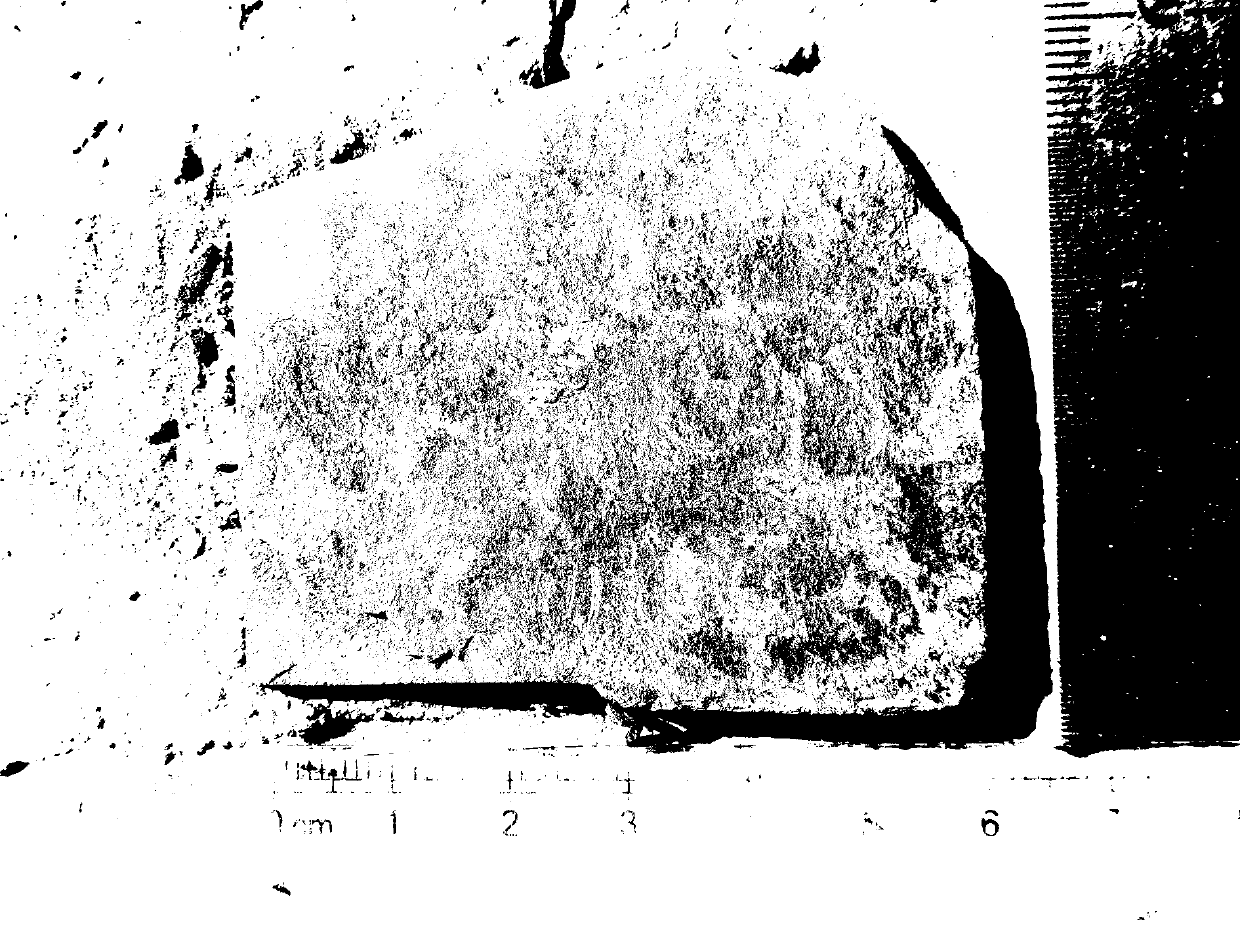

[0055]Place the cut rock mass structural surface in a bright place, and use an ordinary digital camera to take pictures of the cut rock mass structural surface surface. Before taking pictures, it is required to clean the surface of the rock mass structural surface, and at the same time use 1 mm A scale for accuracy is placed alongside as a reference, and the scale should be included in the picture. see Figure 2-Figure 3 When taking pictures, the lens of the digital camera 1 focuses vertically on the rock mass structural surface 2, and selects the close-range mode for shooting to avoid error...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com