Steel rail abrasion measuring method based on dynamic template

A technology of rail wear and measurement method, which is applied in the field of rail transit and can solve problems such as difficulty in matching feature points in template matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

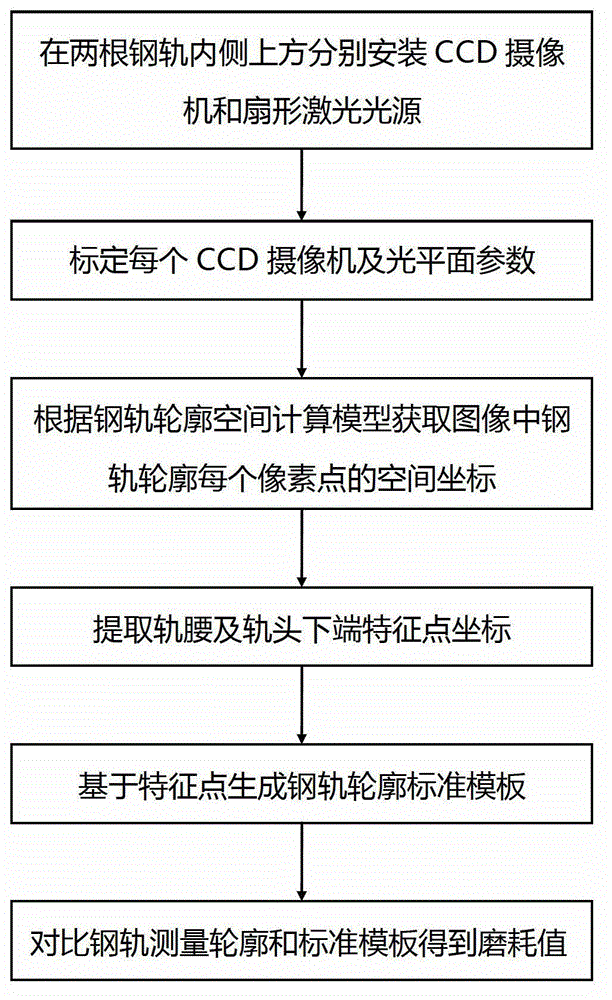

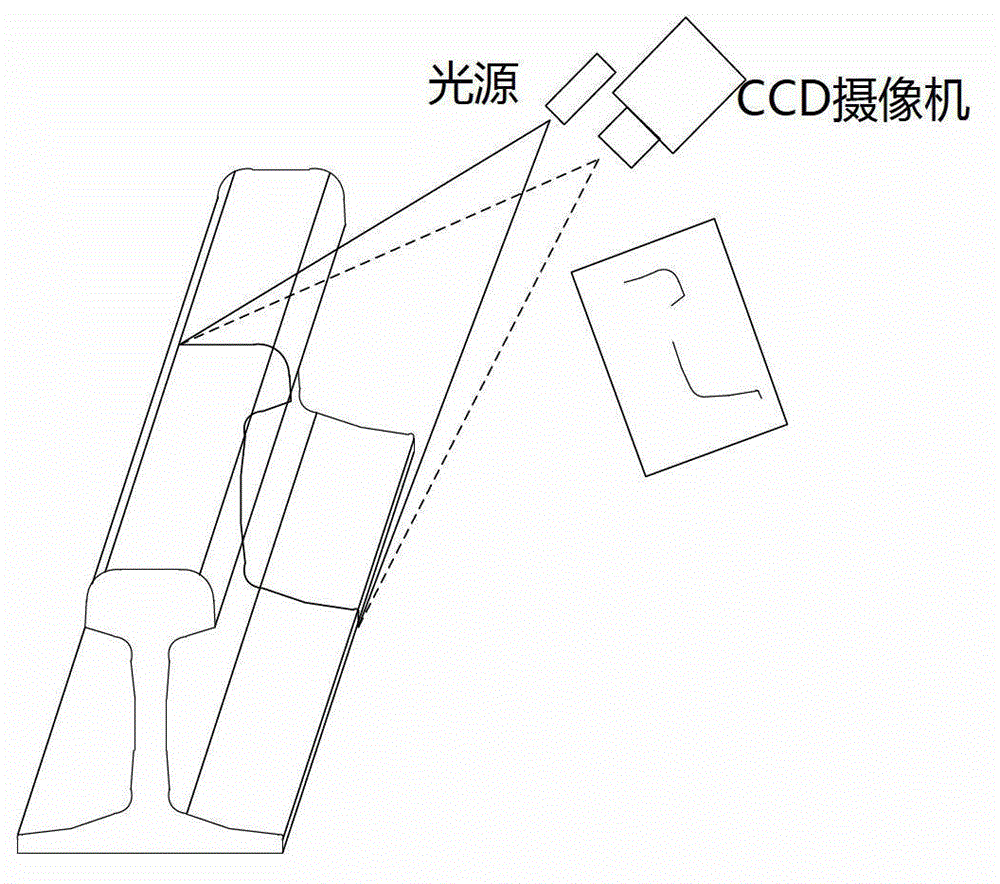

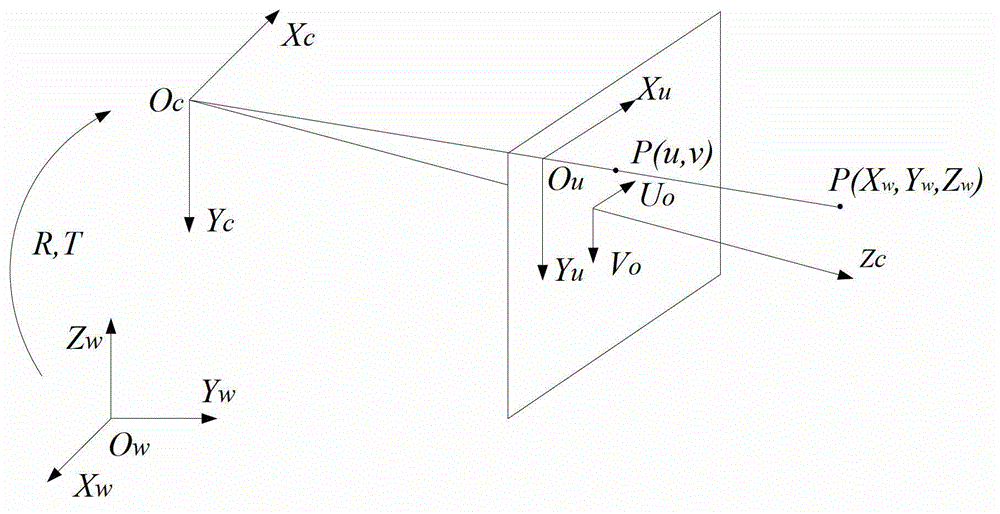

Method used

Image

Examples

Embodiment

[0152] In this embodiment, the standard 60-track is used as the detection object. The camera adopts a CCD industrial camera with a German AVT-FC125 1934 interface, and the resolution is 1280×960 pixels. Image processing and data transfer capabilities. The laser outputs red planar structured light with a wavelength of 635nm and a power of 40mW. In the laboratory, the camera parameters and light plane equation parameters are calibrated first, and the spatial geometric relationship between the camera and the light plane is determined. Take pictures of the profile of 60 standard rail sections, such as Figure 6 As shown, its space curve is obtained after three-dimensional reconstruction, and the theoretical contour space coordinate value of the corresponding position is calculated through the acquisition of feature points. Table 1 lists the measured values of the rail head contour parameters and the dynamically generated template theoretical values. From the perspective of err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com