Bridgeless power factor correction circuit

A power factor correction and circuit technology, applied in circuit devices, emergency protection circuit devices, output power conversion devices, etc., can solve problems such as EMI characteristics that cannot improve work efficiency, and achieve improved EMI characteristics, reduce costs, and improve power density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In order to enable those skilled in the art to better understand and implement the technical solution of the present invention, a bridgeless PFC circuit in the prior art will be firstly introduced below.

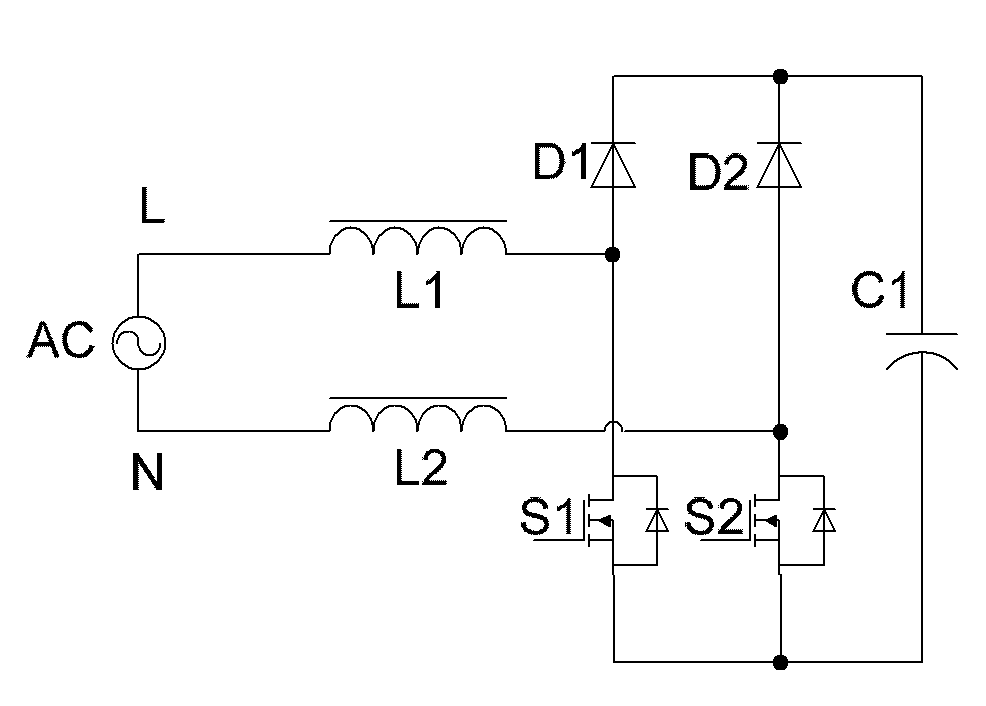

[0060] see Figure 5 , which is a schematic diagram of a bridgeless PFC circuit provided by the prior art.

[0061] The bridgeless PFC circuit includes a high-frequency bridge arm and a low-frequency bridge arm, wherein the high-frequency bridge arm includes a first switch tube S1 and a second switch tube S2 connected in series, and the low-frequency bridge arm includes a series-connected first diode D1 and a second switch tube S2. the second diode D2.

[0062] Both ends of the low-frequency bridge arm and the high-frequency bridge arm are connected in parallel to both ends of the capacitor C1.

[0063] The common end of the first diode D1 and the second diode D2 is connected to one end of the AC power source AC, and the common end of the first switch tube S1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com