Pneumatic control loop for dispensing

A pneumatic control and dispensing technology, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of easy dispensing of dispensing needles and uneven dispensing volume, so as to protect the environment and improve dispensing accuracy. , the effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

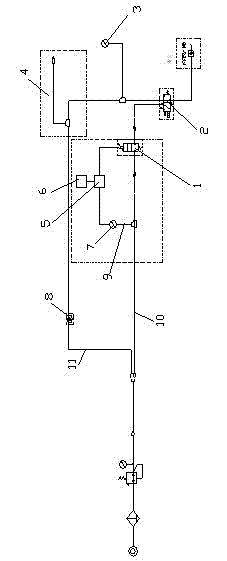

[0008] The present invention is a pneumatic control circuit for dispensing, such as figure 1 As shown, it includes a main pipe 10 connected with a dispensing needle to supply air to the dispensing needle, an electric proportional valve 1 is connected in series on the main pipe 10, and a bypass pipe 9 is provided on the front end of the electric proportional valve 1 , the bypass pipeline 9 is connected with the control interface pipe of the electric proportional valve 1, the pressure switch 7 and the power amplifier 5 are connected in series in the bypass pipeline 9, the power amplifier 5 is connected with the control circuit 6, the bypass pipeline 9, The positive pressure switch 7, the control circuit 6, the power amplifier 5 and the electric proportional valve 1 together constitute a voltage stabilizing device. The main pipeline 10 is connected in parallel with a negative pressure pipeline 11, and the end of the negative pressure pipeline 11 is connected with the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com