Numerical control fixed workpiece excircle processing device

A technology for processing equipment and workpieces, which is applied in the field of non-rotating CNC cylindrical processing equipment for workpieces, can solve problems such as workpiece immobility, and achieve the effects of high precision, high processing efficiency, and good system rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

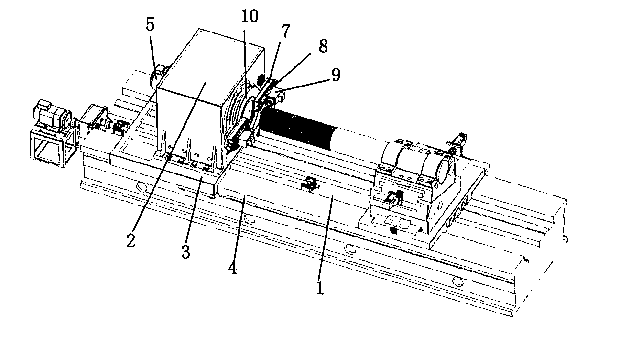

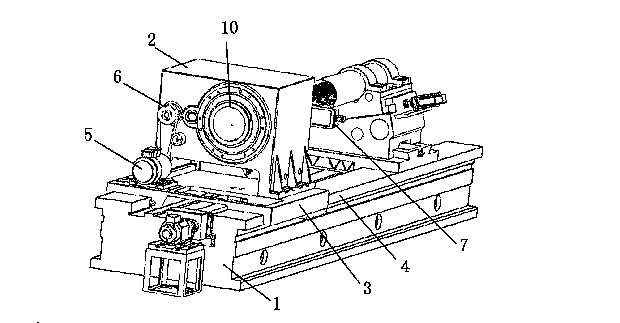

[0018] A kind of embodiment of the present invention is described below in conjunction with accompanying drawing:

[0019] The workpiece is fixed on the bed through a special fixture, and the center is adjusted through the special fixture to align with the spindle 10;

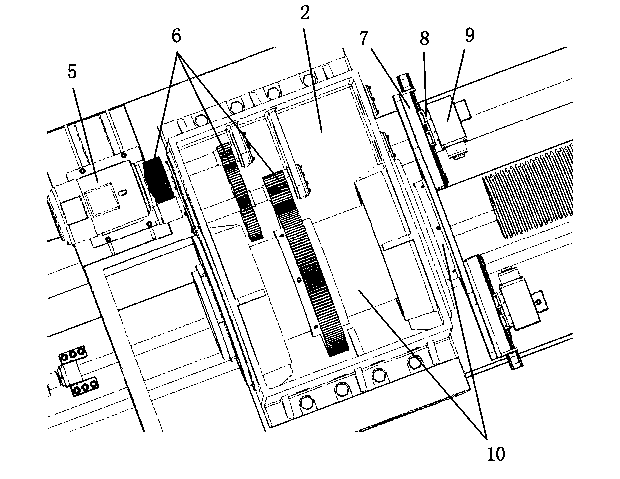

[0020] The spindle box 2 is installed on the spindle box slide 3, and the servo motor located behind the bed 1 is driven by a screw to drive the spindle box slide 3 to make a feed movement along the guide rail 4 on the bed 1, so that the spindle box can move on the workpiece Axial movement; the spindle box 2 includes the spindle frequency conversion motor 5, the reduction device 6, the tool post table 7, the slip table 8 and the air-cooled electric spindle 9; the spindle box frequency conversion motor 5 drives the spindle through the three-stage reduction device 6 10 revolutions, the tool rest table 7 is installed on the spindle 10, the slotted slide table 8 is installed on the tool post table 7, the air-cooled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com